Strong magnetic swirl self-generating vacuum superconducting four-effect wax-proof and viscosity-reducing device

A self-generating, strong magnetic technology, applied in the direction of vibration generating devices, isolation devices, cleaning appliances, etc., can solve difficult and uneconomical problems, and achieve the effects of long time limit, simple and convenient construction, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

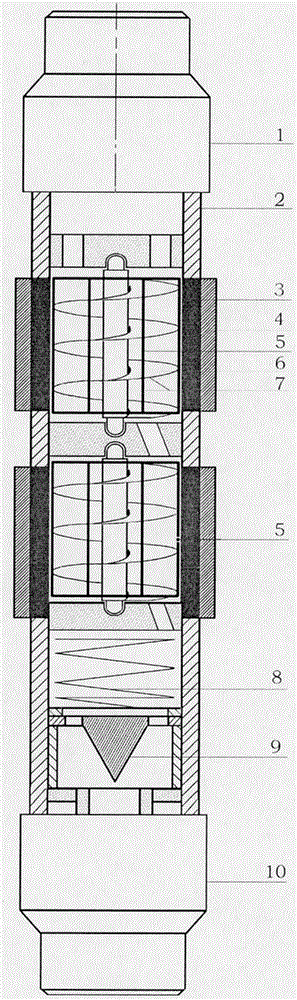

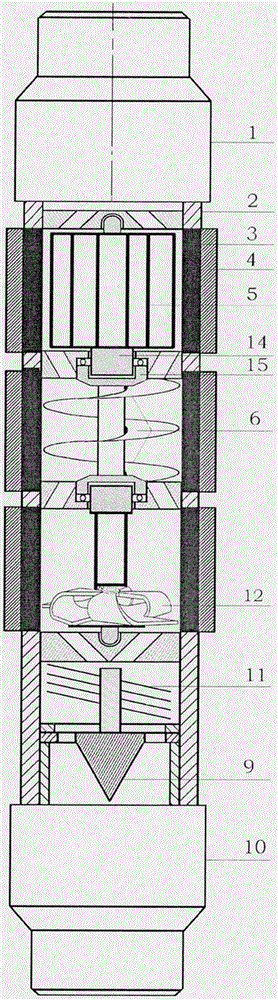

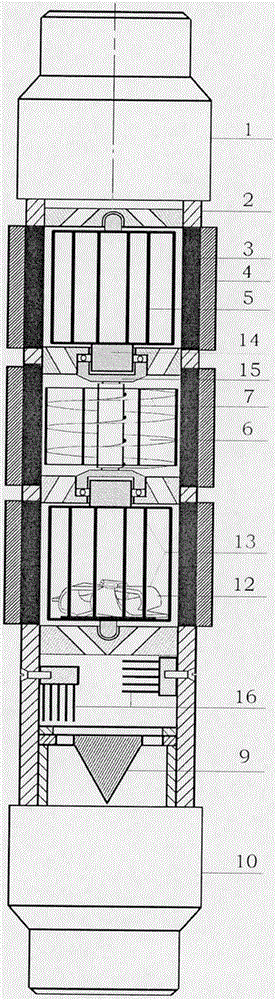

[0043] Such as figure 1 As shown: the strong magnetic swirl self-generating vacuum superconducting four-effect anti-wax viscosity-reducing device of the present invention includes single-stage or multi-stage high-frequency pulse hydraulic oscillation anti-wax viscosity-reducing devices connected in series from bottom to top with threaded fasteners, strong Magnetic swirl self-generating device and strong magnetic swirling self-generating vacuum superconducting four-effect anti-wax viscosity reducing device upper variable buckle joint (1) connected to the oil well pump and strong magnetic swirling self-generating vacuum superconducting four-effect anti-wax The lower variable button joint (10) connected to the tailpipe at the lower part of the viscosity reducing device, wherein the strong magnetic swirl self-generating device is composed of a squirrel cage (5), a strong magnet ring (3), a multi-wing spiral (6) or a multi-wing windmill (12) A five-in-one chamber composed of single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com