Multilayer-structure radar wave-absorbing cloth and preparation method thereof

A multi-layer structure, radar technology, used in coatings, radiation-absorbing coatings, film/flake adhesives, etc. Cost investment and other issues, to achieve the effect of excellent absorbing ability, low cost and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

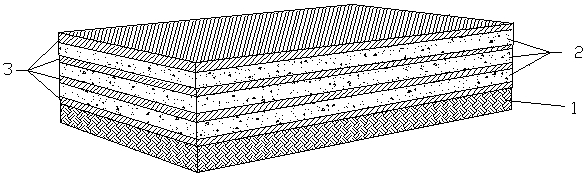

[0034]The preparation of the multi-layer structure radar absorbing cloth of the present invention mainly includes three steps: (1) preparation of magnetic metal alloy micropowder; (2) preparation of wave-absorbing coating; (3) coating of wave-absorbing material.

[0035] According to the prior art, there are mainly two problems to be solved: the preparation of the wave-absorbing coating and the setting of the coating process parameters of the wave-absorbing material.

[0036] The material and preparation method of the present invention require that the powder of the wave-absorbing material layer is a magnetic metal alloy powder, and the alloy powder is calculated by mass ratio, Fe: 85% to 95%, Cr: 0.5% to 5%, Si: 0.1% to 3% %, Al: 0.05% to 7%. The magnetic metal micropowder is a uniform flake, with a diameter of about 2-15 μm and a thickness of about 200 nm.

[0037] The material and preparation method of the present invention, in terms of structural design, according to the ...

example 1

[0042] Example 1: Preparation of multi-layer structure radar absorbing cloth

[0043] Prepare the magnetic metal alloy micropowder according to the proportion, the magnetic metal alloy micropowder of the absorbing material layer is calculated according to the mass percentage proportion, Fe is 85%, Cr is 5%, Si is 3%, and Al is 7%. The magnetic metal alloy powder is prepared by mechanical ball milling;

[0044] (1) First coat a layer of polyurethane adhesive on the surface of the canvas soaked in flame retardant, and dry and cure in an oven at 160 °C for 10 minutes;

[0045] (2) Select the magnetic metal alloy powder with a sheet diameter of 2 μm, dry the magnetic metal alloy powder at 50 °C for 6 hours, then divide it into polyurethane, and stir it evenly to make a wave-absorbing material absorbing coating;

[0046] (3) Step 4, making microwave-absorbing cloth: ①. Coat the surface of the canvas with a layer of polyurethane, the thickness of which is controlled between 10 μm, ...

example 2

[0047] Example 2: Preparation of multi-layer structure radar absorbing cloth

[0048] Prepare the magnetic metal alloy micropowder according to the proportion, the magnetic metal alloy micropowder of the absorbing material layer is calculated according to the mass percentage proportion, Fe is 90%, Cr is 4.5%, Si is 0.1%, and Al is 5.4%. The magnetic metal alloy powder is prepared by mechanical ball milling;

[0049] (1) First coat a layer of polyurethane adhesive on the surface of the canvas soaked in flame retardant, and dry and cure in an oven at 160 °C for 10 minutes;

[0050] (2) Select magnetic metal alloy powder with a sheet diameter of 7 μm, dry the magnetic metal alloy powder at 50 °C for 6 hours, then divide it into polyurethane, and stir it evenly to make a wave-absorbing coating;

[0051] (3) Making microwave-absorbing cloth: ①. Coat the surface of the canvas with a layer of polyurethane, the thickness of which is controlled between 30 μm, and dry and solidify in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com