Method for removing brominated-flame-retardant pollutant in water

A technology of brominated flame retardants and pollutants, which is applied in the design and operation of columnar adsorption devices, can solve the problems of carcinogenesis, impact on brain and bone development, and small removal effect, so as to improve flow state, save pressure demand, and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

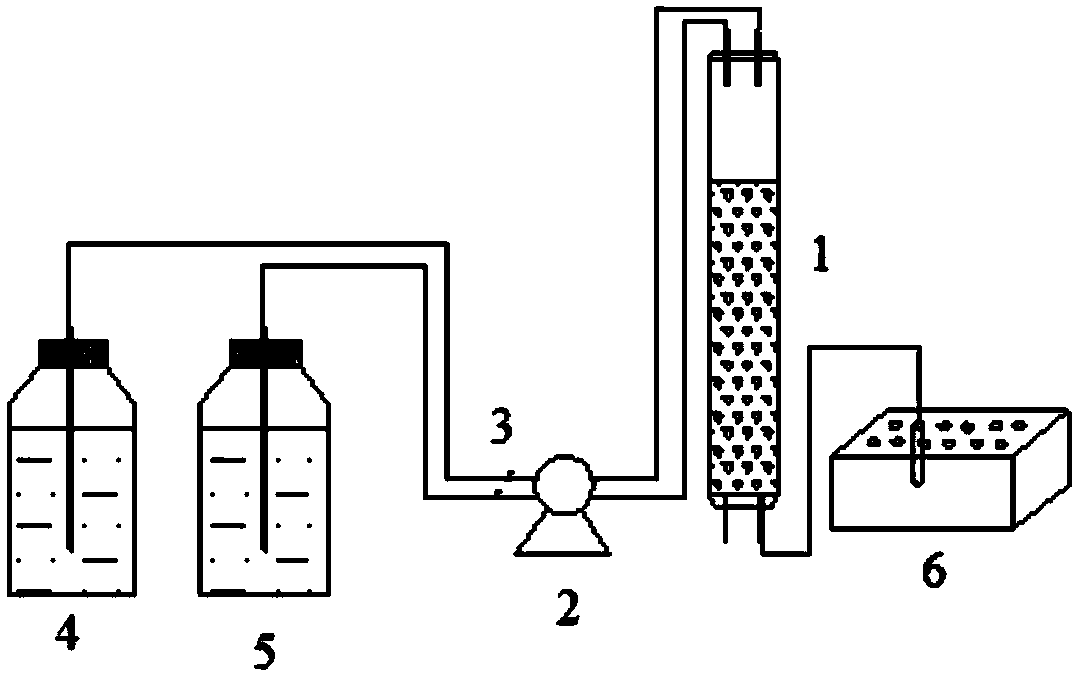

[0023] (1) Use a plexiglass column with a diameter of 5 cm and a length of 40 cm to fill it with fillers. The fillers are 10 cm thick quartz sand and 20 cm thick magnetic ion exchange resin, and fully mix before filling the column. The 50μm microporous membrane prevents the loss of filler, and the water pump uses a vacuum pump with a lift of 8m;

[0024] (2) Before entering the water sample, run it with deionized water for 3.5 hours at a flow rate of 5ml / min, in order to clean the filler;

[0025] (3) The influent water sample contains 3.0mg / L tetrabromobisphenol-A, the flow rate of the whole device is controlled at 3.2ml / min, the effluent water sample is collected with a 50ml centrifuge tube, and is determined by high performance liquid chromatography and mass spectrometry The concentration of tetrabromobisphenol-A in effluent;

[0026] (4) Regeneration is carried out under alkaline conditions (pH=9-11), and the rejuvenating agent is a sodium chloride solution with a mass fr...

Embodiment 2

[0029] (1) Use a plexiglass column with a diameter of 5 cm and a length of 40 cm to fill it with fillers. The fillers are 10 cm thick quartz sand and 20 cm thick magnetic ion exchange resin, and fully mix before filling the column. The 50μm microporous membrane prevents the loss of filler, and the water pump uses a vacuum pump with a lift of 8m;

[0030] (2) Before entering the water sample, run it with deionized water for 3.5 hours at a flow rate of 5ml / min, in order to clean the filler;

[0031] (3) The influent water sample contains 1.0 mg / L of pentabromodiphenyl ether, the flow rate of the whole device is controlled at 2.2ml / min, the effluent water sample is collected in a 50ml centrifuge tube, and the effluent water is determined by high performance liquid chromatography and mass spectrometry. The concentration of tetrabromobisphenol-A;

[0032] (4) Regeneration is carried out under alkaline conditions (pH=9-11), and the rejuvenating agent is a sodium chloride solution w...

Embodiment 3

[0035] (1) Use a plexiglass column with a diameter of 5 cm and a length of 40 cm to fill it with fillers. The fillers are 10 cm thick quartz sand and 20 cm thick magnetic ion exchange resin, and fully mix before filling the column. The 50μm microporous membrane prevents the loss of filler, and the water pump uses a vacuum pump with a lift of 8m;

[0036] (2) Before entering the water sample, run it with deionized water for 3.5 hours at a flow rate of 5ml / min, in order to clean the filler;

[0037] (3) The influent water sample contains 1.0mg / L decabromodiphenyl ether, the flow rate of the whole device is controlled at 2.0ml / min, the effluent water sample is collected in a 50ml centrifuge tube, and the effluent water is determined by high performance liquid chromatography and mass spectrometry. The concentration of tetrabromobisphenol-A;

[0038] (4) Regeneration is carried out under alkaline conditions (pH=9-11), and the rejuvenating agent is a sodium chloride solution with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com