Fireproof heat-preserving glass-fiber aluminum-foil membrane

A technology of fire prevention and heat preservation, glass fiber aluminum, applied in the direction of heat preservation, fire prevention, glass/slag layered products, etc., can solve the problems that the effect of aluminum foil paper is very different, fire prevention is not a grade, etc., achieve good insulation, improve molding processing performance, improve the effect of fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

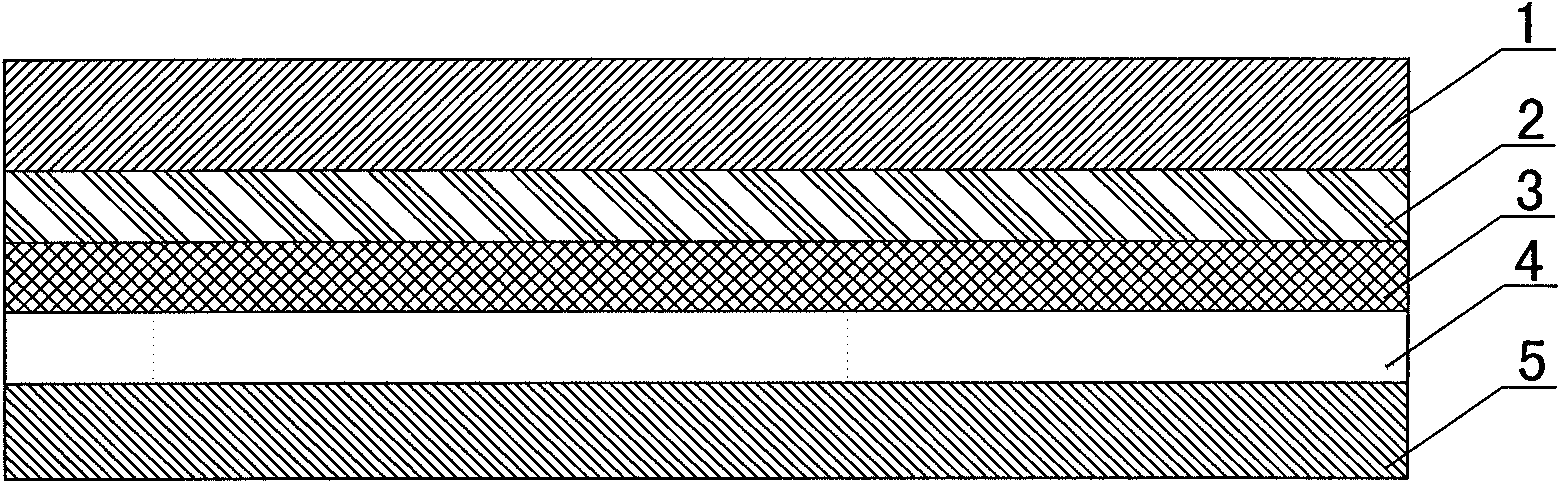

[0021] Such as figure 1 As shown, the fire-proof and thermal insulation glass fiber aluminum foil film described in the embodiment of the present invention includes glass fiber cloth 1, and selects 115~125g / m 2 A glass fiber cloth 1 with the advantages of good insulation, strong heat resistance, good corrosion resistance, and high mechanical strength. The outer surface of one side of the glass fiber cloth 1 is provided with a layer of weight of 16-20g / m 2 The biaxially stretched polyester film 2 made up for the poor wear resistance of the glass fiber cloth. Evenly set 17~21g / m 2 The middle layer 3 of aluminum foil paper, one of the upper and lower surfaces of the middle layer 3 of aluminum foil paper is combined with the biaxially stretched polyester film 2, and the other surface is combined with the 17-21g / m 2 The biaxially stretched nylon film 4 is bonded, and the outer layer of the biaxially stretched nylon film 4 is coated with a weight of 76-83g / m 2 Low-density polyeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com