A kind of preparation method of soft magnetic composite material

A technology of soft magnetic composite material and soft magnetic powder, which is applied in the field of magnetic materials, can solve the problems of magnetic dilution, magnetic powder core permeability and magnetization reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The steps of the soft magnetic composite material preparation method are as follows:

[0020] 1) Preparation of sol: Fe 3+ The salt is dissolved in ethylene glycol solution to make Fe 3+ The solubility is 2mol / L, heated to 30~50 o C, stirring for 1~3h to form a sol;

[0021] 2) Coating of metal soft magnetic alloy: Add soft magnetic powder into the sol, stir and mix thoroughly, heat to 60~90 o C, keep warm until the gel is obtained; age the gel for 1~4h, then heat it at 80~120 o Dry under C conditions for 3~5h, and the dry gel after drying is at 200~400 o Anneal in an inert gas of C for 3~5h; obtain coated soft magnetic powder, the amount of soft magnetic powder makes the mass percentage of soft magnetic powder in the final product be 70~99%, Fe 3 o 4 The mass percentage in the product is 1~30%;

[0022] 3) Add binder: Take the coated soft magnetic powder with a mass fraction of 0.5-2.5% of the binder and pour it into the soft magnetic powder treated in step 2). ...

Embodiment 1

[0028] 0.02mol Fe(NO 3 ) 3 Dissolve in 10ml of ethylene glycol, heat to 40 o C and stir for 2h, then add 60g iron powder, heat to 80 o C and stirred until a gel was obtained, and the obtained gel was aged for 2h at 120 o Dry under C condition for 4h, the xerogel obtained at 400 o C temperature under the condition of nitrogen protection under heat treatment for 4h.

[0029] The iron powder obtained is added in the mixed solution of 2wt% epoxy resin and 10wt% acetone, at 80 o Stir under the condition of C until the powder is dry, then add 0.5wt% barium stearate, and press it into a dense ring shape under the condition of 800MPa, for the ring sample at 400 o Annealed under C condition for 1h to make a soft magnetic composite material.

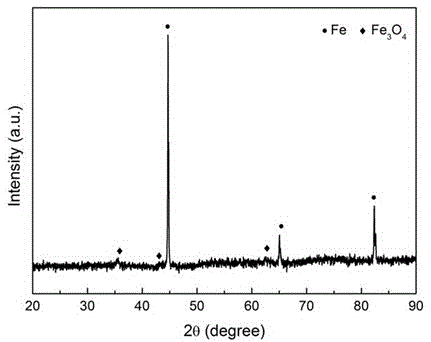

[0030] After testing, the magnetization of the soft magnetic alloy is 1.6T, and the magnetic permeability is 80, figure 1 For iron powder surface generation Fe in embodiment 1 3 o 4 X-ray (XRD) spectrum lines of core-shell composite soft ...

Embodiment 2

[0032] 0.2mol FeCl 3 Dissolve in 100ml of ethylene glycol, heat to 30 o C and stirred for 3h, then added 150g sendust powder, heated to 60 o C and stirred until a gel was obtained, and the obtained gel was aged for 1 h at 80 o C condition is dried 3h, and the xerogel obtained is at 200 o C temperature under the condition of argon protection under heat treatment for 5h.

[0033] Add 1.5wt% silicone resin, 1.0wt% SiO to the obtained alloy powder 2 In a mixed solution with 10wt% acetone, at 80 oStir under C conditions until the powder is dry, then add 0.25wt% zinc stearate and 0.25wt% barium stearate, and press it into a dense ring shape under the condition of 2000MPa. o Annealed under C condition for 2h to make a soft magnetic composite material.

[0034] After testing, the magnetization of the soft magnetic alloy is 1.2T, and the magnetic permeability is 92.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com