Oriented electromagnetic steel plate and manufacturing method therefor

A technology of electromagnetic steel sheet and manufacturing method, applied in the direction of inductance/transformer/magnet manufacturing, manufacturing tools, circuits, etc., can solve problems such as insulation, corrosion resistance will not recover, magnetic degradation, insulation film damage, etc., to achieve insulation and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

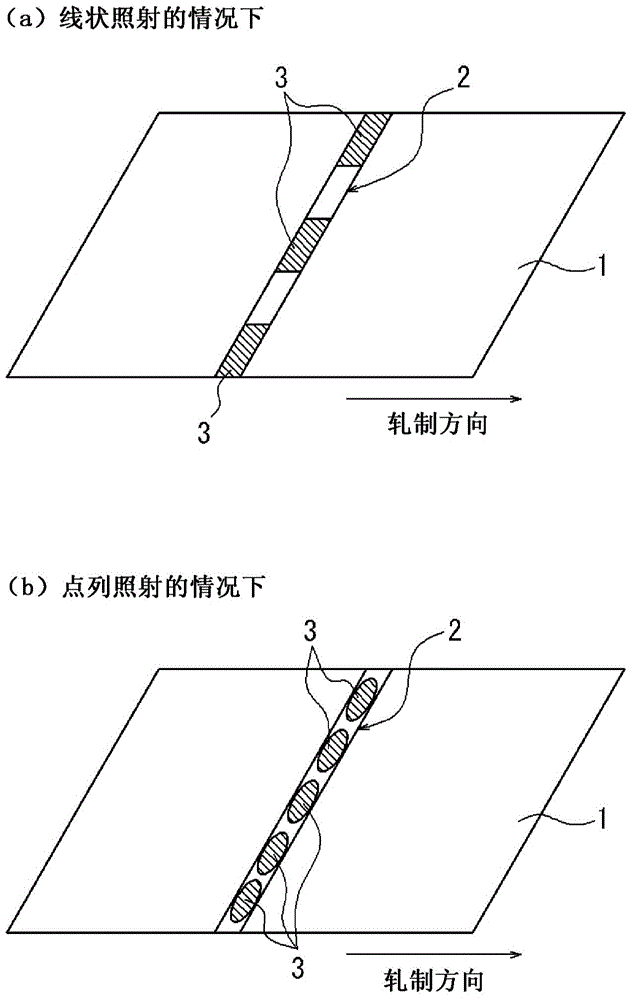

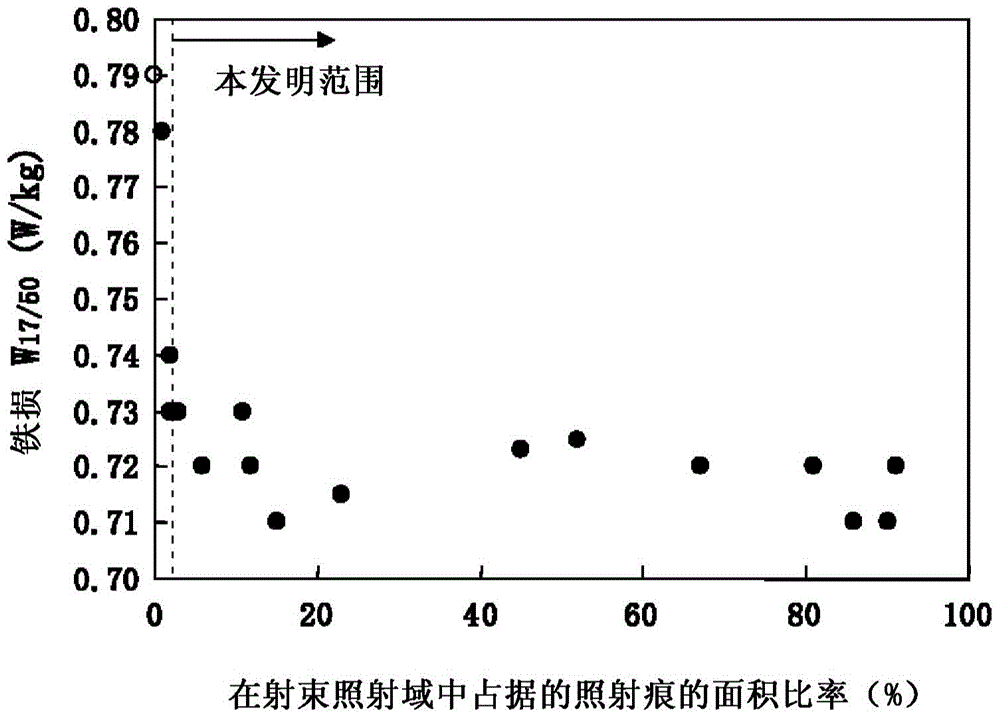

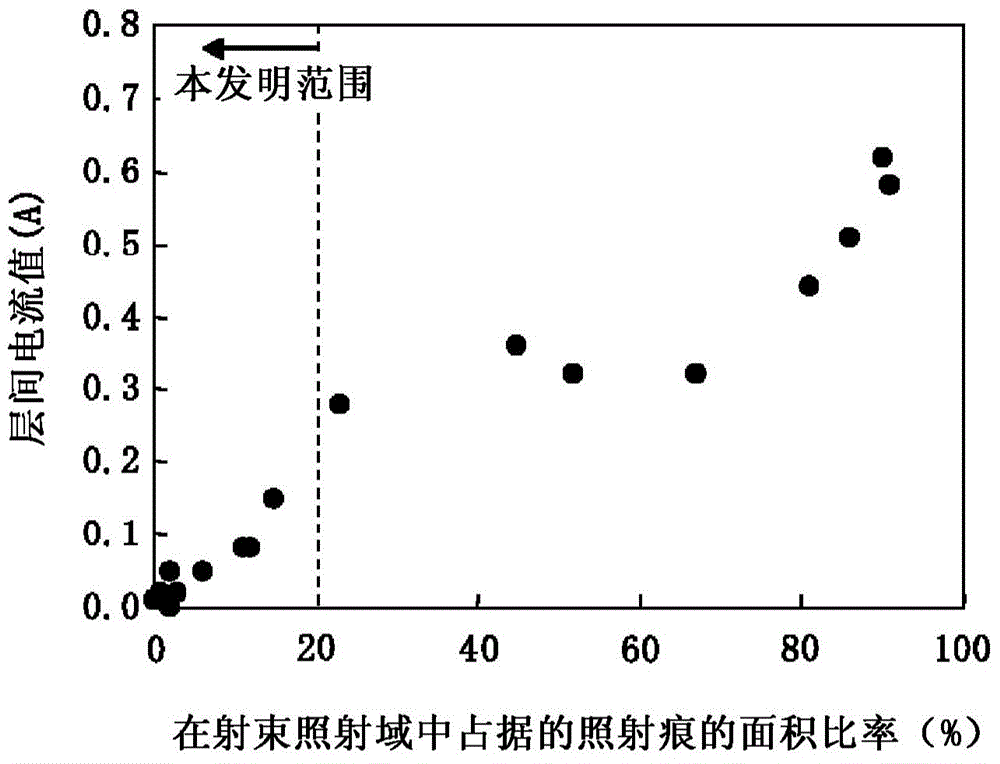

[0126] For a compound containing 3.25 mass % of Si, 0.04 mass % of Mn, 0.01 mass % of Ni, 60 mass ppm of Al, 20 mass ppm of S, 250 mass ppm of C, 16 mass ppm of O and 40 mass ppm of N The grain-oriented electrical steel sheet rolled to a final thickness of 0.23mm is decarburized with a cold-rolled sheet, and after primary recrystallization annealing, an annealing separator with MgO as the main component is applied, and the secondary recrystallization process and purification process are carried out. Final annealing was performed to obtain a grain-oriented electrical steel sheet having a forsterite coating. Then, the following coating solution A was applied to the steel sheet, and fired at 800° C. to form an insulating film. Thereafter, continuous fiber laser irradiation or Q-switched pulsed laser irradiation was performed on the insulating film at intervals of 3 mm along the rolling direction perpendicular to the rolling direction to perform magnetic domain refining treatment....

Embodiment 2

[0135] Containing the same composition as in Example 1, the grain-oriented electrical steel sheet rolled into a final plate thickness of 0.23 mm is decarburized and primary recrystallization annealed with a cold-rolled sheet, and then coated with MgO as an annealing separator as a main component. The final annealing including the secondary recrystallization process and the purification process obtains a grain-oriented electrical steel sheet with a forsterite coating. Then, the coating liquid A in the above-mentioned Example 1 was applied to the steel sheet, and fired at 800° C. to form an insulating film. Thereafter, the insulating film was irradiated with electron beams at intervals of 3 mm in the rolling direction perpendicular to the rolling direction and the vacuum degree of the processing chamber was 1 Pa, or continuously irradiated to perform magnetic domain refinement treatment. As a result, the magnetic flux density B 8 A material whose value is 1.92T to 1.94T.

[01...

Embodiment 3

[0141] The final plate thickness is rolled to 3.3% by mass of Si, 0.08% by mass of Mn, 0.05% by mass of Cu, 0.002% by mass of Al, 0.001% by mass of S, 0.06% by mass of C, and 0.002% by mass of N After decarburization and primary recrystallization annealing are performed on the 0.23mm grain-oriented electrical steel sheet, a part of the cold-rolled sheet is treated as a coil in a batch of salt bath for nitrogen treatment, which increases the amount of N in the steel by 700ppm. Thereafter, an annealing separator mainly composed of MgO was applied, and final annealing including a secondary recrystallization process and a purification process was performed to obtain a grain-oriented electrical steel sheet with a forsterite coating. Next, the coating solution A in Example 1 described above was applied to the grain-oriented electrical steel sheet, and fired at 800° C. to form an insulating film. Thereafter, the insulating film was irradiated with electron beams at intervals of 3 mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com