Lightweighting high-strength composite material vehicle shelter panel

A composite material, high-strength technology, used in chemical instruments and methods, synthetic resin layered products, building components, etc., can solve the problem of thermal stress shelter slab debonding, self-heavy shelter slabs, and complex load conditions. and other problems, to achieve the effect of reducing assembly costs, short manufacturing time, and easy daily maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

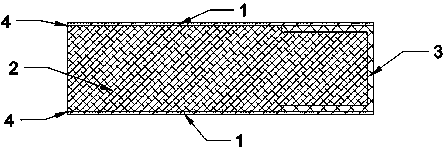

[0019] Such as figure 1 As shown, this embodiment provides a large board for a vehicle-mounted shelter made of composite materials, including a skin 1 , a middle foam interlayer, and surrounding edges 3 . The skin 1 includes an inner skin and an outer skin. The skin 1 used is made of carbon fiber satin fabric prepreg and glass fiber fabric prepreg as raw materials, and is formed by a vacuum oven process. Carbon fiber satin fabric prepreg provides sufficient strength, stiffness and flat appearance, while glass fiber fabric prepreg provides sufficient impact performance, and the vacuum oven process greatly reduces the cost of manufacturing. The resin used in the prepreg is flame-retardant epoxy resin, and the resin content in the prepreg is 35% to 45%.

[0020] The surrounding edge 3 used adopts a U-shaped structure, with carbon fiber twill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com