Reduction Distillation Furnace Used in Sponge Titanium Production

A distillation furnace and furnace shell technology, applied in the field of sponge titanium production, can solve the problems of unrealized recycling and achieve the effects of shortening the production cycle, increasing the speed of reduction and feeding, and reducing power consumption and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

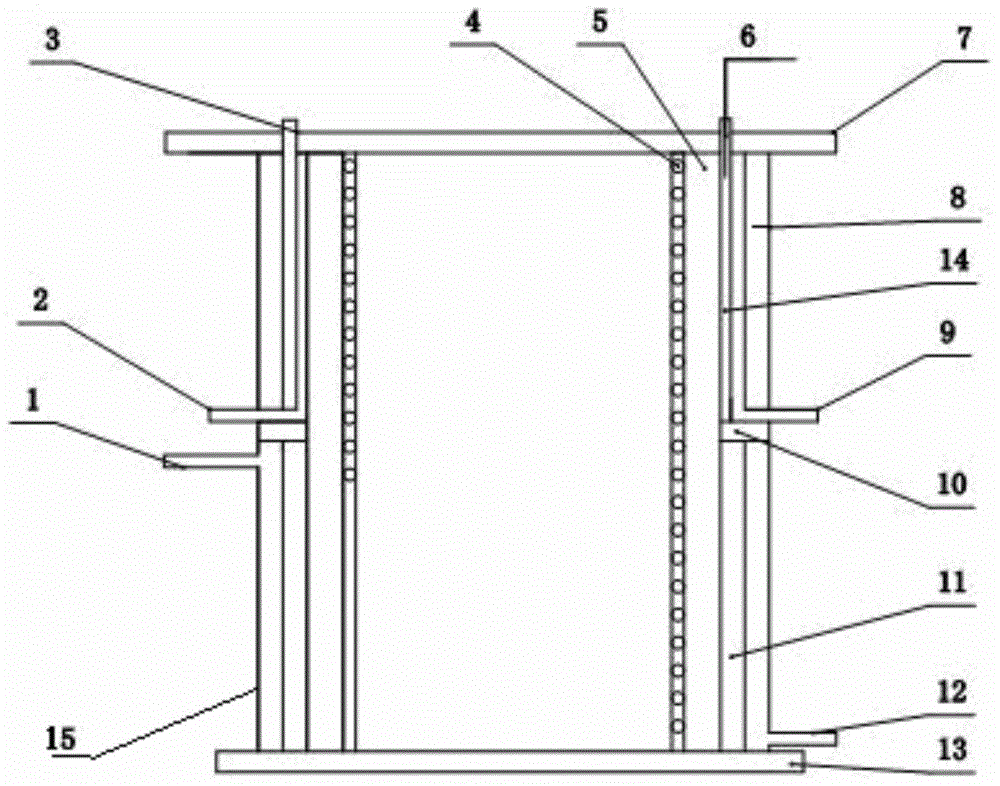

[0016] Such as figure 1 As shown, a reduction distillation furnace for the production of sponge titanium is mainly composed of a furnace shell 15, a heating element 4, a flange 7, and a furnace bottom 13. The furnace shell 15 is connected to the flange 7 and the furnace bottom 13, respectively, The shell 15 is provided with a heating element 4 and an external insulation layer 8. The isolation plate 10 divides the reduction distillation furnace into an upper half and a lower half. A condenser is provided in the outer insulation layer 8 of the upper half of the reduction distillation furnace The cooling medium inlet pipe 9 is arranged above the isolation plate 10, the cooling medium outlet pipe 3 passes through the flange 7, and a gap 14 and a drain pipe 2 are provided between the internal insulation layer 5 and the condenser. The flange 7 is provided with a pressure relief port 6, and an intermediate thermal insulation layer 11 is provided between the external thermal insulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com