A medical stone dissolution system and process for preparing edible oil

A technology of edible oil and medical stone, applied in the direction of edible oil/fat, application, food science, etc., can solve the problems of destroying the quality of healthy life, not completely eliminating health risks, heavy metals in raw materials, excessive pesticide residues, etc., to achieve full Automatic process, unique internal structure, simple installation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

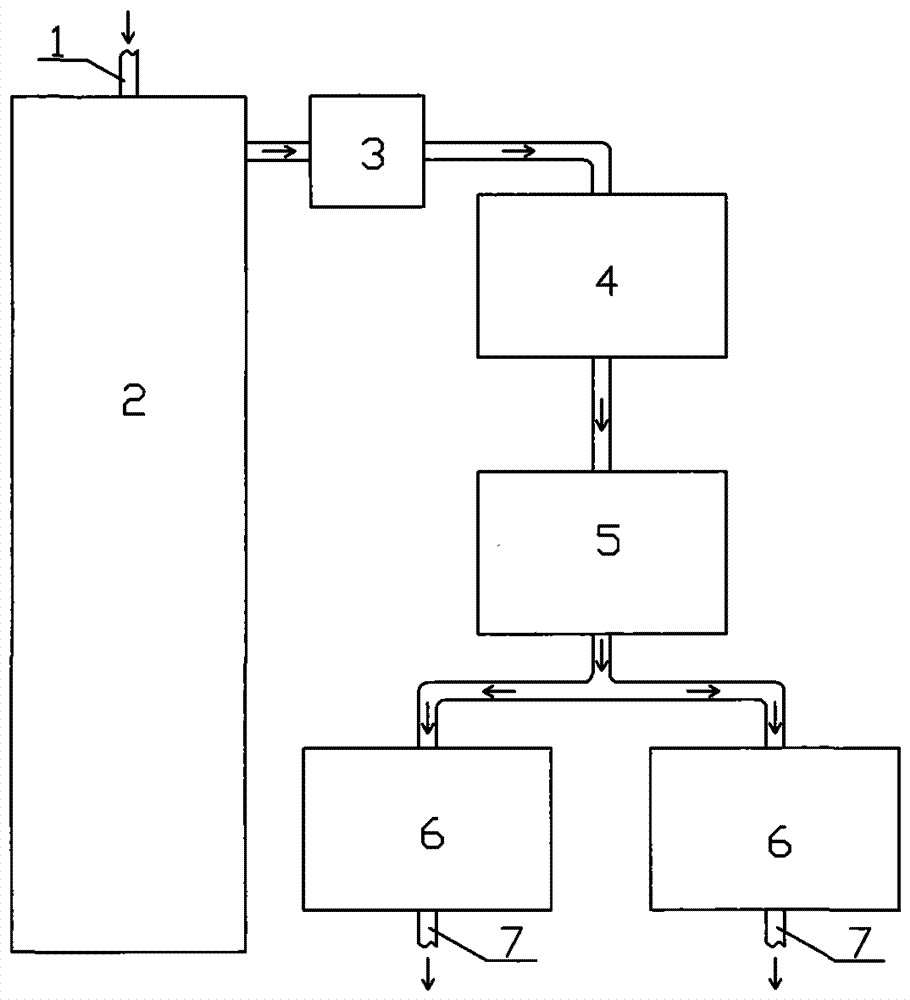

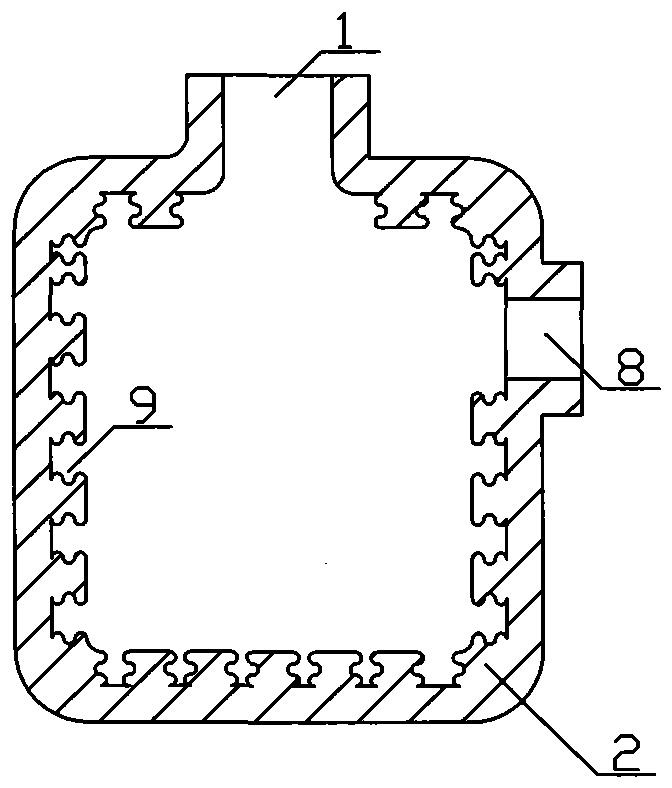

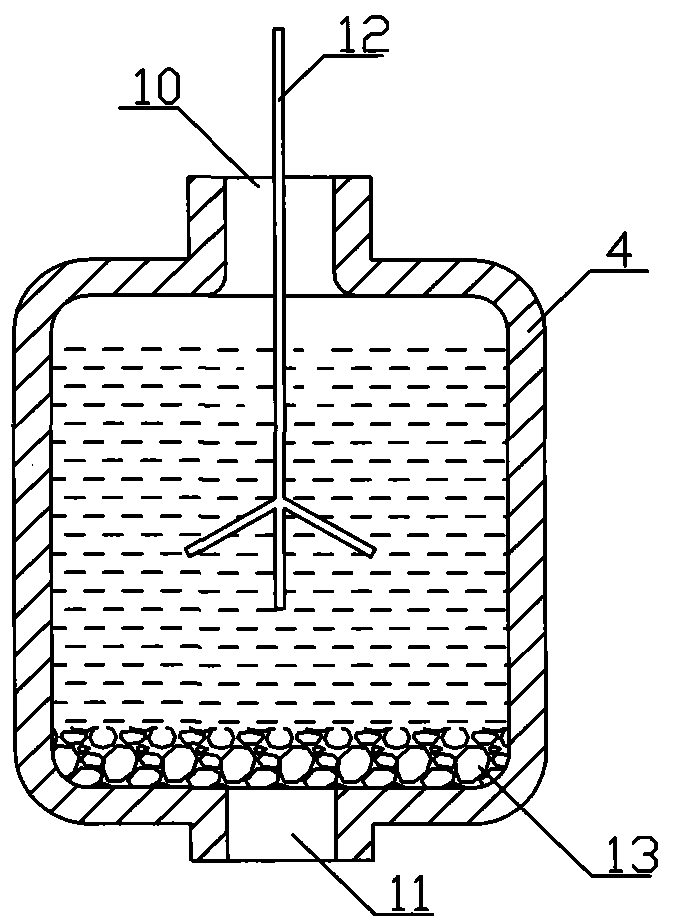

[0041] Embodiment 1: as figure 1 Shown, a kind of medical stone stripping system that is used to prepare edible oil, it comprises sedimentation tank, hydraulic pump 3, physical adsorber, weak ionization filter, two static regulators; figure 2 As shown, the settling tank comprises a settling tank body 2 made of medical stone with an average pore size of 0.09---0.13 micron, and the wall thickness of the settling tank body 2 is 8cm; There is a raw material input pipe 1, and a sedimentation tank outlet 8 is provided on the side wall of the sedimentation tank body 2; grooves 9 are evenly arranged on the inner wall of the sedimentation tank body 2, so as to maximize the surface area of the inner wall of the sedimentation tank body 2 The ratio of the contact area of edible oil in the sedimentation tank body 2 to the inner wall of the sedimentation tank body 2 and the overall surface area of the edible oil is 1 / 12, can also be 1 / 8.5, or 1 / 7, which can make the medical stone It...

Embodiment 2

[0042] Embodiment 2: a kind of process that is used to prepare the medical stone stripping system of edible oil to produce edible oil, it adopts the stripping system among the embodiment 1, and it comprises the steps:

[0043] Step 1, inject conventionally produced edible oil through the raw material input pipe 1 into the settling tank made of medical stone with an average pore size of 0.09 microns and place it for 18 hours, and the edible oil in the settling tank body 2 and the settling tank 2 The ratio of the contact area of the inner wall to the overall surface area of edible oil is 1 / 12, so that the medical stone contained in the sedimentation tank 2 contains eleven kinds of constant elements such as potassium, calcium, magnesium, manganese, and anti-cancer germanium, Fourteen kinds of trace elements such as strontium, molybdenum and vanadium are fully dissolved in the edible oil, increasing the oxygen content in the edible oil, and carrying out a certain degree of prel...

Embodiment 3

[0049] Embodiment 3: a kind of process that is used to prepare the medical stone stripping system of edible oil to produce edible oil, it adopts the stripping system among the embodiment 1, and it comprises the steps:

[0050] Step 1, inject conventionally produced edible oil through the raw material input pipe 1 into the settling tank made of medical stone with an average pore size of 0.13 microns and place it for 36 hours, the edible oil in the settling tank body 2 and the settling tank body 2 The ratio of the contact area of the inner wall to the overall surface area of edible oil is 1 / 7, so that the medical stone contained in the sedimentation tank body 2 contains eleven kinds of constant elements such as potassium, calcium, magnesium, manganese, and anti-cancer germanium, Fourteen kinds of trace elements such as strontium, molybdenum and vanadium are fully dissolved in the edible oil, increasing the oxygen content in the edible oil, and carrying out a certain degree of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com