A kind of coal pyrolysis gas dry purification, cracking and fraction recovery device and process

A dry purification and recovery device technology, applied in chemical recovery, gas dedusting, petroleum industry, etc., can solve the problems of wasting sensible heat of gas, low utilization value, wasting energy, etc. Effects of avoiding maintenance operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

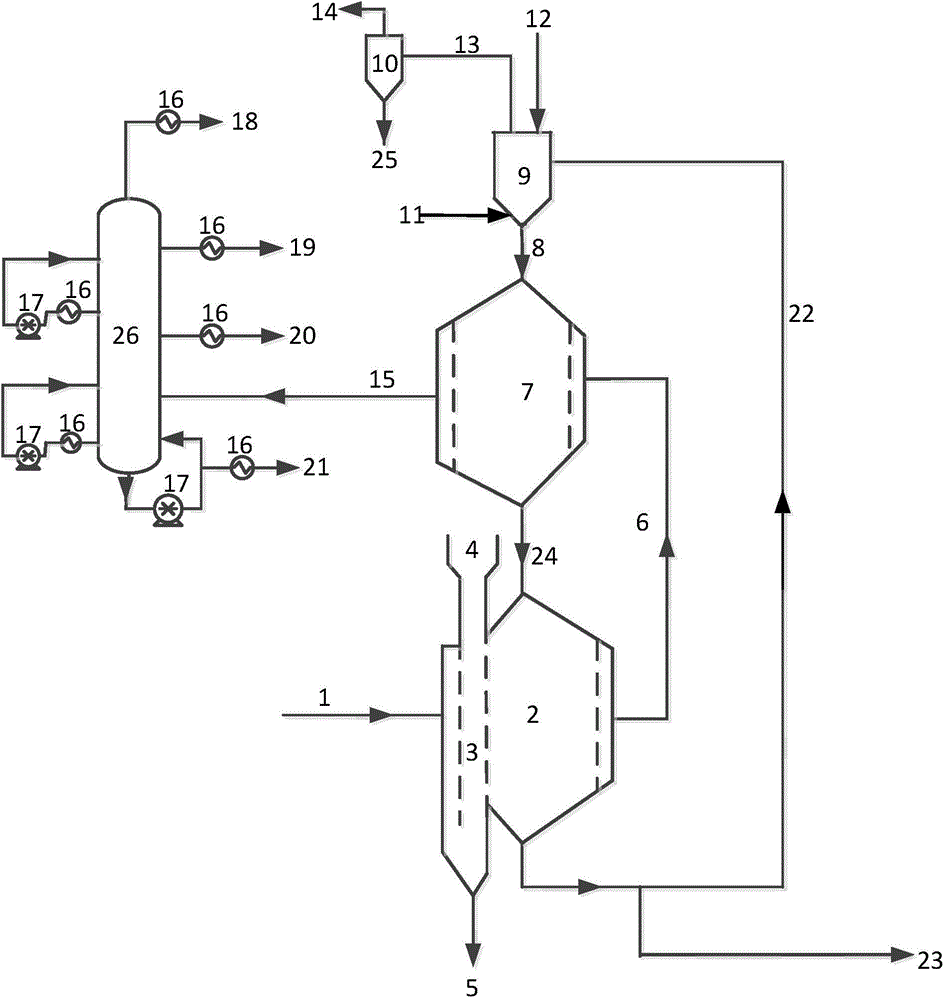

[0028] In conjunction with the accompanying drawings, a coal pyrolysis gas dry purification, cracking and fraction recovery device includes a lower catalytic bed 2, an upper catalytic bed 7 and a composite fractionation tower 26. The lower catalytic bed is divided into a lower catalytic bed dust removal area 3 and a lower catalytic bed. There are two parts of the bed catalytic area, the dust removal area and the catalytic area are separated by louver baffles, the louver baffles are vertically arranged, and the bottom end is inserted into the middle and lower part of the lower catalytic bed dust removal area 3. The dust removal area 3 of the lower catalytic bed is connected with the pyrolysis gas inlet pipe 1, the upper part of the dust removal area is provided with a dust removal filter material feeding hopper 4, and the lower part of the dust removal area is provided with a dusty filter material discharge pipe 5. The catalytic zone is connected to the upper catalytic bed 7 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com