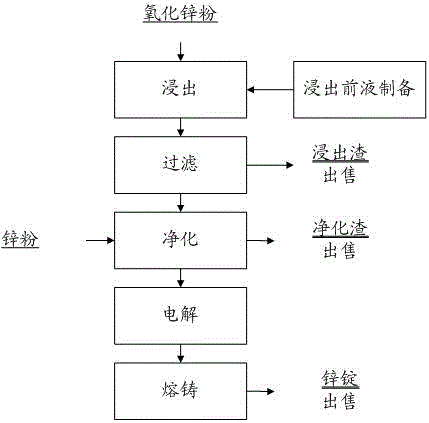

Method for extracting electrodeposited zinc from zinc oxide powder in ammonium chloride solution system

A technology of ammonium chloride solution and zinc oxide powder is applied in the improvement of process efficiency, photography process, instruments and other directions, which can solve the problems of high cost, long process flow, and fluorine-chlorine waste water, etc., and achieves short process and high production load. The effect of controlling and solving environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The zinc oxide powder produced by the volatilization of ironmaking blast furnace dust through volatilization kiln is used as raw material, and the ingredients (the materials in the present invention are all mass percentages unless otherwise specified): Zn53.3, Fe3.7, Cl 9.2, F0.5 , Pb7.6;

[0052] Ammonium chloride solution system is used to prepare the pre-leaching solution so that its composition reaches NH 4 + 90g / l, NH 3 45g / l;

[0053] Leaching: add 28m to the leaching tank 3 For the solution before leaching, correspondingly add 4.7 tons of zinc oxide powder, the leaching temperature is 35°C, the leaching time is 0.5 hours, the zinc leaching rate is 93.1%, and the filtrate after leaching (i.e. leachate, g / l): Zn82.7, Pb0.53, Cu0.004;

[0054] Purification: zinc powder is added according to twice the total theoretical calculation amount of lead, copper, cadmium and cobalt in the leaching solution (3g / l-leach solution, that is, 1l leaching solution is added with...

Embodiment 2

[0058] Zinc oxide powder produced by volatilization of lead smelting fuming furnace is used as raw material, composition (%): Zn61.6, Fe4.7, Cl 0.71, Cu0.035, Pb10.3.

[0059] Prepare the pre-leaching solution so that its composition reaches NH 4 + 110g / l, NH 3 50g / l;

[0060] Leaching: add 28m to the leaching tank 3 For the pre-leaching solution, correspondingly add 4 tons of zinc oxide powder, the leaching temperature is 40°C, and the leaching time is 2 hours. The zinc leaching rate is 92.1%, and the filtrate composition after leaching (g / l): Zn81.1, Pb0.0053, Cu0.0032, Cd0.0062;

[0061] Purification: add zinc powder (0.2g / l-leach solution) based on 18 times the total theoretical amount of lead, copper, cadmium and cobalt in the leaching solution, the purification time is 1.5 hours, the purification temperature is 35°C, and the impurity composition of the purification solution (mg / l) : Pb0.051, Cu0.03, Cd0.02, Co0.23;

[0062] Electrowinning: Graphite is used as the a...

Embodiment 3

[0065] Zinc dross produced by zinc smelting industrial frequency furnace is used as raw material, composition (%): Zn73.3, Fe2.1, Cl 4.2, Cu0.8, Pb3.7;

[0066] Prepare the pre-leaching solution so that its composition reaches NH 4 + 95g / l, NH 3 45g / l;

[0067] Leaching: add 28m to the leaching tank 3 For the pre-leaching solution, correspondingly add 4 tons of zinc scum, the leaching temperature is 30°C, and the leaching time is 4 hours. The zinc leaching rate is 95.1%, and the filtrate composition after leaching (g / l): Zn99.5, Pb0.005, Cu0.001, Cd0.001;

[0068] Purification: add zinc powder according to 25 times the total theoretical calculation amount of lead, copper, cadmium and cobalt in the leaching solution, the purification time is 0.5 hours, the purification temperature is 30 ℃, the impurity composition of the purification solution (mg / l): Pb0.03, Cu0.01, Cd0.02, Co0.08;

[0069] Electrowinning: Graphite is used as the anode, the same pole distance is 75mm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com