Method for purifying pentachlorophenol in water through photocatalysis

A technology for purifying water and pentachlorophenol, applied in the field of environmental photocatalysis, can solve the problems of severe reaction conditions, PCP pollution, poor purification ability, etc., and achieve the effect of simple equipment, short process and high purification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

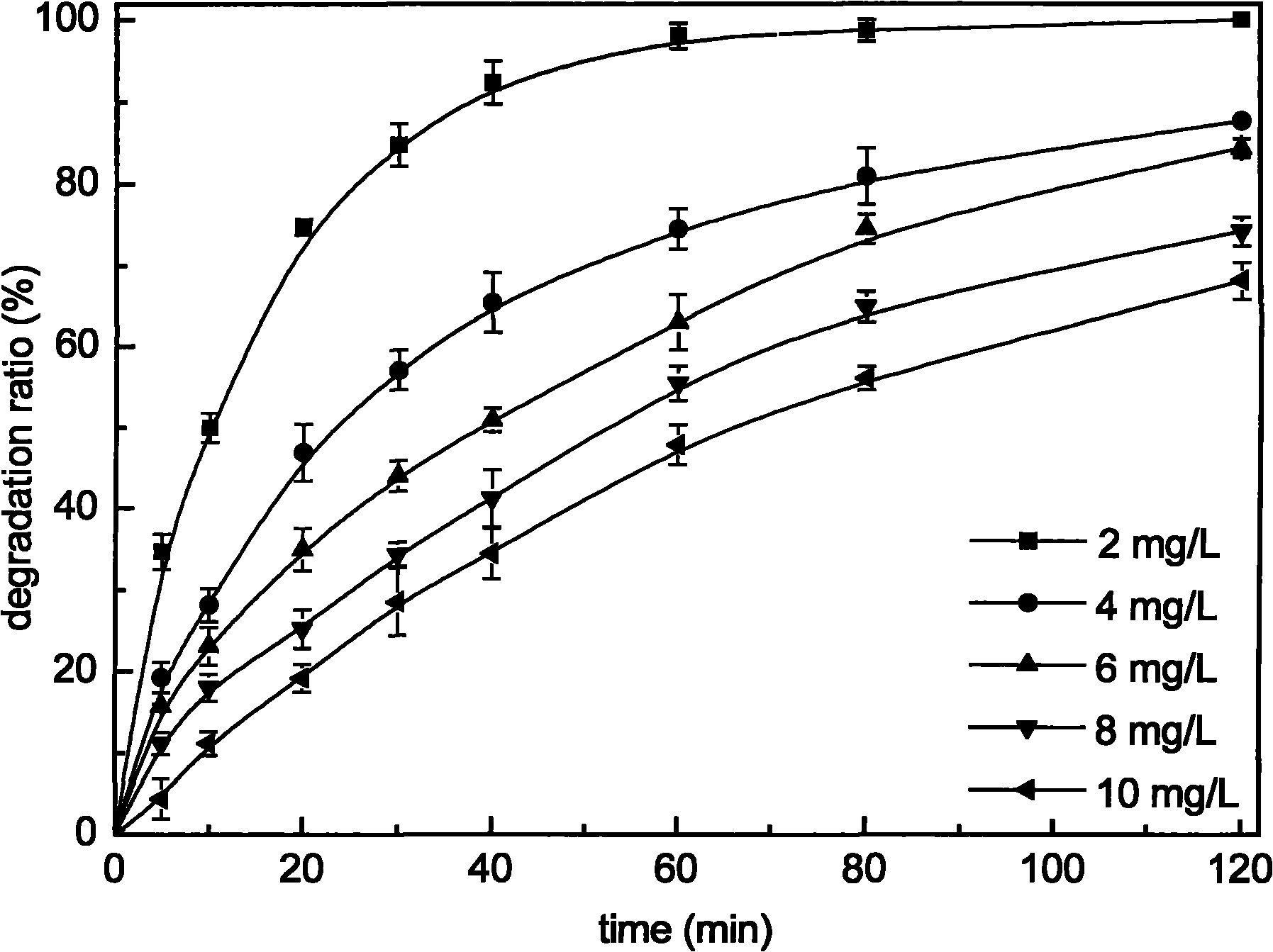

[0028] Disperse 50 mg of bismuth silicate powder in 200 ml of PCP solution with an initial concentration of 2 mg / L, and ultrasonicate the mixture for 10 minutes under dark conditions to completely disperse the catalyst in the solution. Before irradiation, the mixture was magnetically stirred for 30 minutes in the dark to achieve adsorption equilibrium, and then irradiated with a 500-watt xenon lamp (wavelength 300-800 nm), adjusting the distance between the reaction liquid level and the head of the xenon lamp to be 20 cm. During the process of photocatalytic degradation, magnetic stirring is used to make the reaction solution uniform, and the temperature of the reaction solution is kept at (20±2) degrees by a water bath. Take 1 ml samples regularly, centrifuge to get the supernatant, and use HPLC to analyze the concentration of PCP after sampling. The results showed that after the reaction was carried out for 2 hours, the degradation rate of PCP was greater than 99.0%.

Embodiment 2

[0030] Disperse 50 mg of bismuth silicate powder in 200 ml of PCP solution with an initial concentration of 4 mg / L, and ultrasonicate the mixture for 10 minutes in the dark to completely disperse the catalyst in the solution. Before irradiation, the mixture was magnetically stirred for 30 minutes in the dark to achieve adsorption equilibrium, and then irradiated with a 500-watt xenon lamp (wavelength 300-800 nm), adjusting the distance between the reaction liquid level and the head of the xenon lamp to be 20 cm. During the process of photocatalytic degradation, magnetic stirring is used to make the reaction solution uniform, and the temperature of the reaction solution is kept at (20±2) degrees by a water bath. 1 ml samples were taken regularly, the supernatant was taken after centrifugation, and the concentration of PCP was analyzed by HPLC after sampling. The results showed that after 2 hours of reaction, the degradation rate of PCP reached 87.7%.

Embodiment 3

[0032] Disperse 50 mg of bismuth silicate powder in 200 ml of PCP solution with an initial concentration of 6 mg / L, and ultrasonicate the mixture for 10 minutes under dark conditions to completely disperse the catalyst in the solution. Before irradiation, the mixture was magnetically stirred for 30 minutes in the dark to achieve adsorption equilibrium, and then irradiated with a 500-watt xenon lamp (wavelength 300-800 nm), adjusting the distance between the reaction liquid level and the head of the xenon lamp to be 20 cm. During the process of photocatalytic degradation, magnetic stirring is used to make the reaction solution uniform, and the temperature of the reaction solution is kept at (20±2) degrees by a water bath. 1 ml samples were taken regularly, the supernatant was taken after centrifugation, and the concentration of PCP was analyzed by HPLC after sampling. The results showed that the degradation rate of PCP reached 84.5% after the reaction was carried out for 2 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com