Aluminum alloy surface treatment method

An aluminum alloy surface, aluminum alloy technology, applied in the direction of surface reaction electrolytic coating, electrolytic coating, anodizing, etc., can solve the problems of the effect of the sealing process, the complicated operation, the influence of the inherent performance of the aluminum alloy, etc., to achieve low cost and high efficiency The effect of production efficiency and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

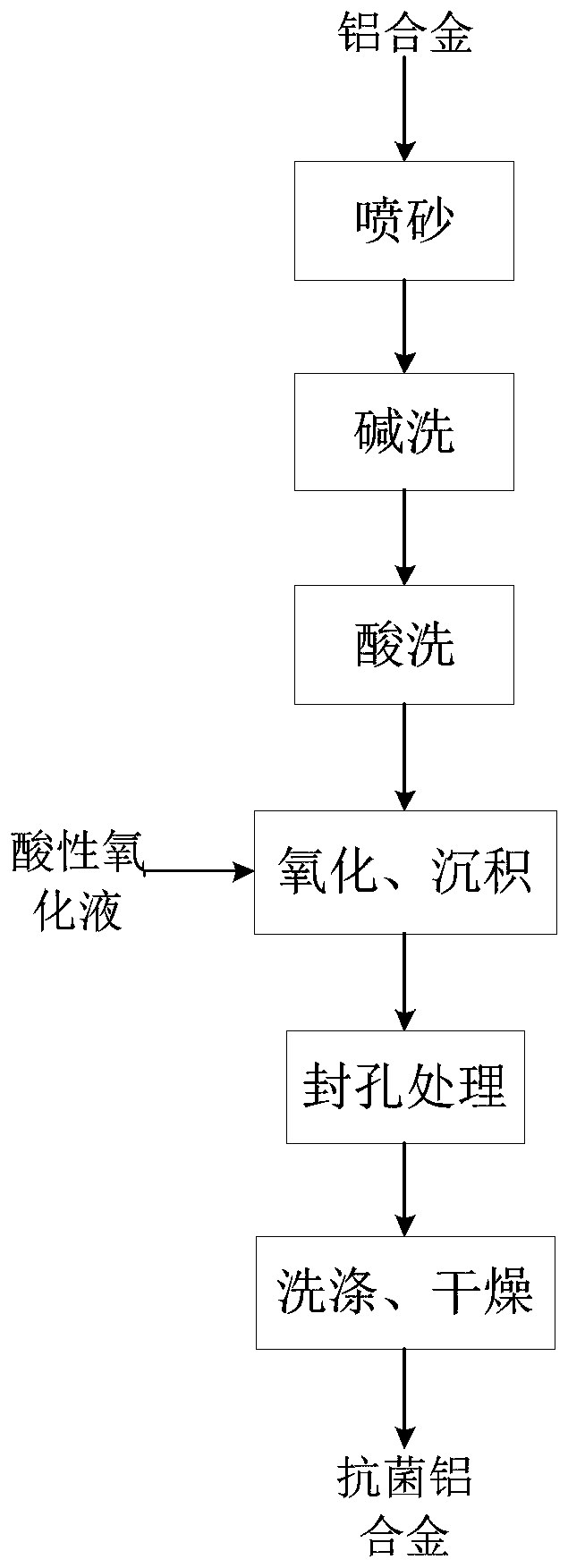

[0058] This embodiment provides a method for aluminum alloy surface treatment, the process flow chart of the method is as follows figure 1 shown, including the following steps:

[0059] (1) Sand blast the aluminum alloy first, the particle size of the sand used is 100 mesh, and then use 50g / L sodium hydroxide solution for alkaline cleaning for 5 minutes. Carry out pickling, the solution used for pickling is 200g / L nitric acid solution, pickling treatment at 20°C for 5 minutes, wash with deionized water and then blow dry;

[0060] (2) Place the aluminum alloy processed in step (1) in an acidic oxidation solution, wherein the composition of the acidic oxidation solution is: sulfuric acid 150g / L, silver nitrate 0.8g / L, aluminum sulfate 32g / L, cerium nitrate 10g / L L, oxidation and deposition are carried out alternately under the conditions of power supply voltage 30V and alternating current, the time of alternating current is 1min in the positive direction and 1min in the negativ...

Embodiment 2

[0063] This embodiment provides a method for surface treatment of an aluminum alloy, the method comprising the following steps:

[0064] (1) Sand blast the aluminum alloy first, the particle size of the sand used is 50 mesh, and then use 40g / L sodium hydroxide solution for alkali washing treatment for 6 minutes. Carry out pickling, the solution used for pickling is 180g / L nitric acid solution, pickling treatment at 25°C for 6 minutes, wash with deionized water and then blow dry;

[0065] (2) Place the aluminum alloy processed in step (1) in acidic oxidation solution, wherein the composition of acidic oxidation solution is: sulfuric acid 140g / L, silver nitrate 1.2g / L, aluminum nitrate 35g / L, cerium nitrate 15g / L L, under the condition of power supply voltage of 25V and alternating current, oxidation and deposition are carried out alternately. The time of alternating current is 1.2min in the positive direction and 0.8min in the negative direction, and the current density of the ...

Embodiment 3

[0068] This embodiment provides a method for surface treatment of an aluminum alloy, the method comprising the following steps:

[0069] (1) Sand blast the aluminum alloy first, the particle size of the sand used is 150 mesh, and then use 45g / L potassium hydroxide solution for alkali washing treatment for 3 minutes, the temperature of alkali washing is 32 °C, after washing with deionized water Carry out pickling, the solution used for pickling is 190g / L nitric acid solution, pickling at 30°C for 4 minutes, washing with deionized water and drying;

[0070] (2) Place the aluminum alloy processed in step (1) in an acidic oxidation solution, wherein the composition of the acidic oxidation solution is: sulfuric acid 145g / L, silver nitrate 1.0g / L, aluminum sulfate 30g / L, cerium nitrate 12g / L L, under the condition of power supply voltage of 35V and alternating current, oxidation and deposition are alternately carried out. The time of alternating current is 0.8min in the positive dir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com