Method of recovering lead from scrap lead-acid storage battery lead plaster

A technology for waste lead-acid batteries and lead paste is applied in the field of recovering lead from waste lead-acid battery lead paste, which can solve the problems of high energy consumption cost and high energy consumption of lead paste, and achieve low cost, low energy consumption and reagent consumption. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

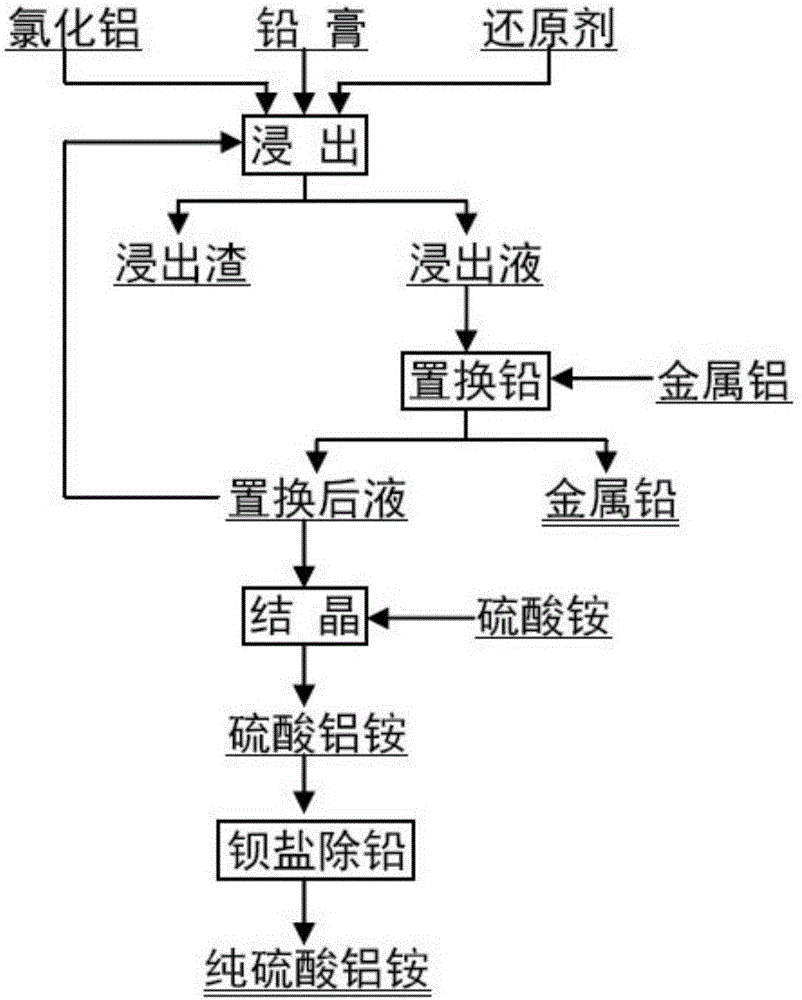

Method used

Image

Examples

Embodiment 1

[0022] Leaching: 1kg lead paste (Pb 71.1%), leaching agent is 350g / L aluminum chloride solution, reducing agent FeCl 2 4H 2 The amount of O is 0.4kg, the leaching temperature is 80°C, the leaching time is 2h, and the liquid-solid ratio is 35.5:1. Lead leaching rate reaches 98.9%.

[0023] Replacement of lead: use aluminum plate as the replacement agent, the replacement temperature is 30°C, the amount of aluminum plate is 1 times the theoretical amount, and the replacement is 1h to obtain a total of 702g of fine lead sludge with a lead content of 99.1%.

[0024] Aluminum ammonium sulfate crystallization: at room temperature at 25°C, add 500g / L (NH 4 ) 2 SO 4 Solution, form ammonium aluminum sulfate crystallization precipitation, control the sulfate radical concentration in the solution at 20g / L.

[0025] Lead removal with barium salt: After dissolving ammonium aluminum sulfate crystals, add barium carbonate, and obtain pure ammonium aluminum sulfate after recrystallization...

Embodiment 2

[0027] Leaching: 1kg zinc leaching residue (Pb 65.7%), leaching agent is 350g / L aluminum chloride solution, reducing agent hydrogen peroxide dosage is 300mL, leaching temperature is 70℃, leaching time is 2h, liquid-solid ratio is 28.5:1. Lead leaching rate reaches 95.7%.

[0028] Replacement of lead: use aluminum block as the replacement agent, the replacement temperature is 30°C, the amount of aluminum block is 1 times the theoretical amount, and the replacement is for 1 hour to obtain a total of 627g of fine lead sludge with a lead content of 99.2%.

[0029] Aluminum ammonium sulfate crystallization: at room temperature at 25°C, add 500g / L (NH 4 ) 2 SO 4 Solution, form ammonium aluminum sulfate crystallization precipitation, control the sulfate radical concentration in the solution at 20g / L.

[0030] Lead removal with barium salt: After dissolving ammonium aluminum sulfate crystals, add barium carbonate, and obtain pure ammonium aluminum sulfate after recrystallization. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com