Low-halogen polypropylene flame-resistant materials and preparing method thereof

A flame retardant material, polypropylene technology, applied in the field of polypropylene flame retardant, phenylphosphinate and brominated flame retardant compound flame retardant PP field, can solve the problem of large amount of addition, affecting the processing performance and physical properties of PP products Performance, environmental pollution and other issues, to achieve the effect of reducing the amount of addition, excellent electrical performance, and meeting environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

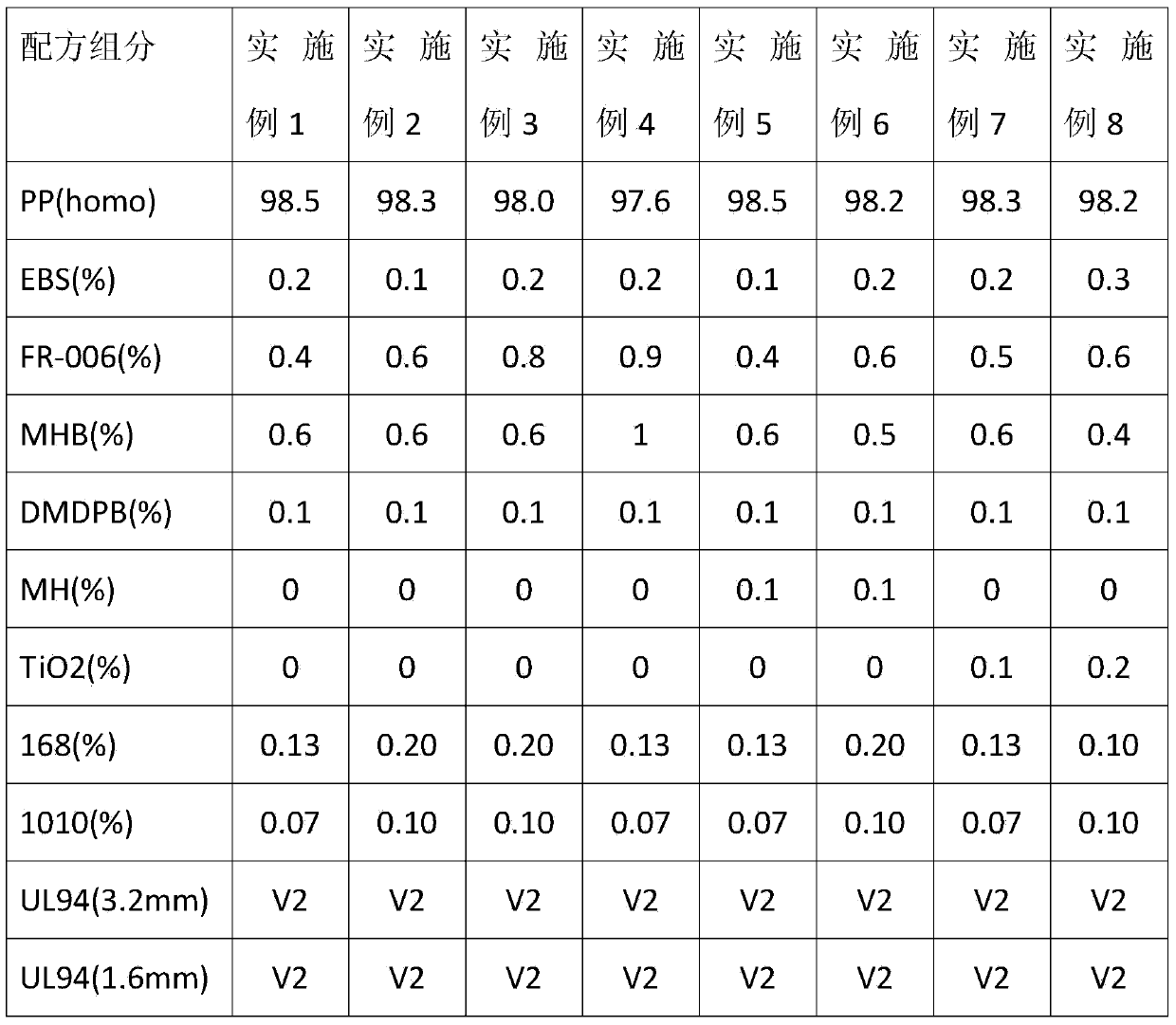

[0029] Examples 1-8 are the flame retardant effects of FR-006 and MHB compound flame retardant PP. The ratio of each raw material is shown in Table 1. The general method of the experimental process: Weigh the raw materials according to the weight percentage, and stir each component in a high-speed mixer. The flame retardant PP material is obtained by lower extrusion granulation.

[0030] Table I

[0031]

[0032] As can be seen from the data analysis in Table 1: Examples 1-8 keep the DMDPB addition 0.1wt% constant, discuss FR-006, MHB (melamine hydrobromide), DMDPB (2,3-dimethyl-2, 3-diphenylbutane) compounded on the flame retardancy of PP. Because DMDPB is used as a free radical initiator in PP flame retardancy, it promotes the breakage of PP molecular chains, and then promotes the droplet dripping; while bromine can promote the droplet non-combustibility, so as to promote dripping and flame retardancy; among them, the implementation Example 1: The total addition amoun...

Embodiment 9-16

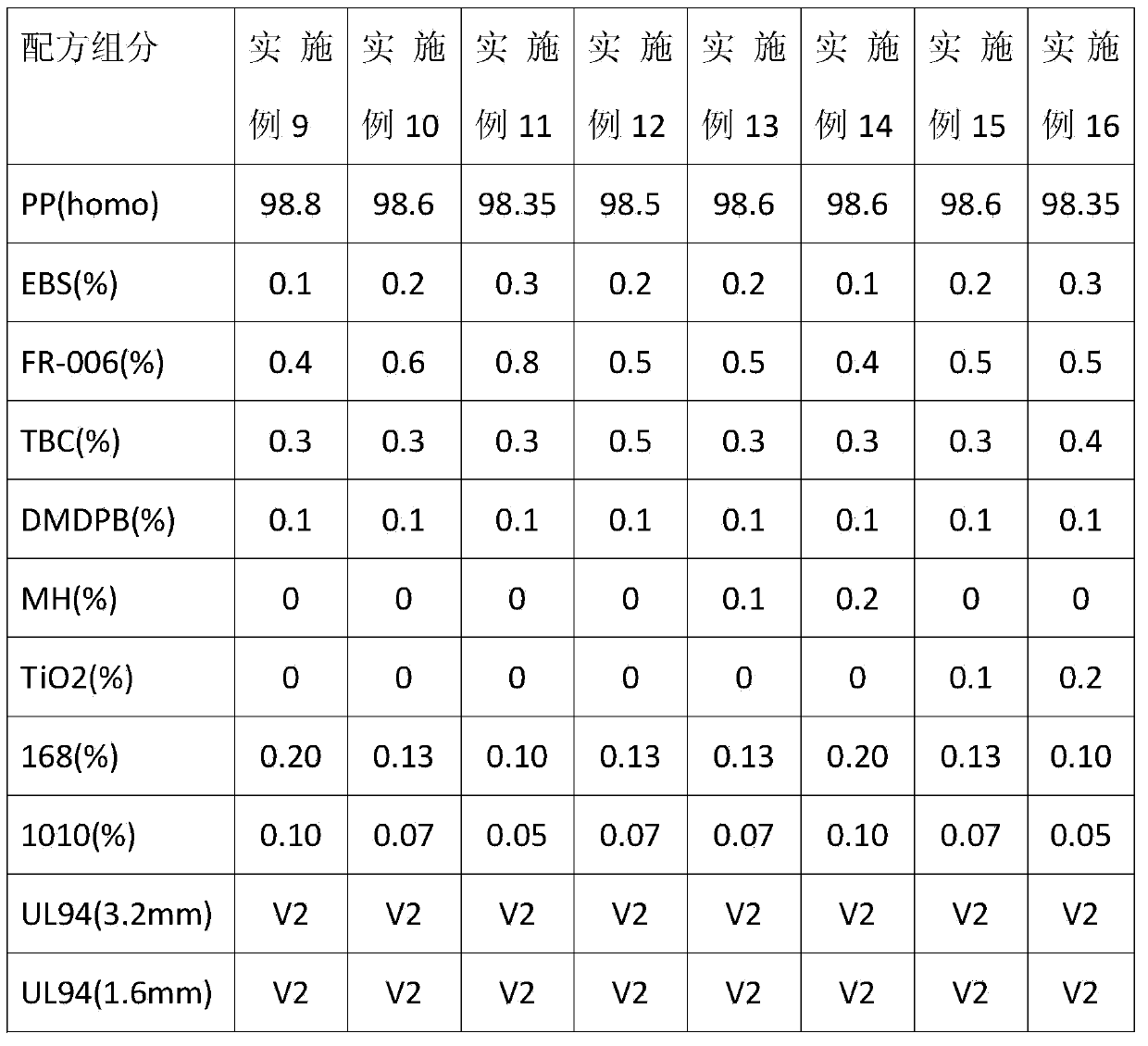

[0034] Examples 9-16 are the flame retardant effects of FR-006 and TBC compounded flame retardant PP, the ratio of each raw material is shown in Table 2, and the preparation process is the same as the example in Table 1.

[0035] Table II

[0036]

[0037]As can be seen from the data analysis in Table 2, the embodiment 9-16 keeps the 0.1wt% addition of DMDPB unchanged, and studies FR-006, three (2,3-dibromopropyl) isocyanurate (TBC), The flame retardant effect of DMDPB on PP. The role of DMDPB (2,3-dimethyl-2,3-diphenylbutane) in PP flame retardancy exists as a free radical initiator. Wherein embodiment 15: FR-006, TBC, DMDPB total addition amount just can reach UL941.6mm V2 level at 0.8wt%; When maintaining the addition amount of TBC0.3wt% in embodiment 13-14, add inorganic particle hydrogen oxidation Magnesium (MH), when MH is 0.1-0.2wt%, the flame-retardant PP can reach UL941.6mm V2 level, and 0.5wt% of phenylphosphinate aluminum (FR006) is added in Examples 15-16, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com