Thermal conductive SMA (stone mastic asphalt) asphalt concrete used for electric snow melting asphalt pavement

A technology of asphalt concrete and asphalt pavement, which is applied in the field of road materials, can solve the problems of increasing the amount of asphalt, storage difficulties, and inconvenient construction, and achieves the effect of increasing high temperature stability, improving high temperature stability, and simple construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0026] The heat-conducting SMA asphalt concrete of this embodiment is first prepared graphite asphalt, graphite is added to the heated asphalt; and then the asphalt mixture is produced according to the traditional process. The graphite used replaces 10% of the mass of mineral powder, that is, 1% of the total mass of asphalt mixture is added with graphite; the content of fibers (lignin fiber or modified lignin fiber, carbon fiber) used is 3‰~5‰ of the mass of asphalt concrete; The asphalt used is SBS modified asphalt, and the dosage is 6.5% of the aggregate mass; the graphite used is flaky graphite, and the specific technical indicators are shown in Table 3; the stone used is basalt, and the specific gradation is implemented with reference to SMA-13; The ore powder is limestone, and the synthetic gradation is shown in Table 4.

[0027]

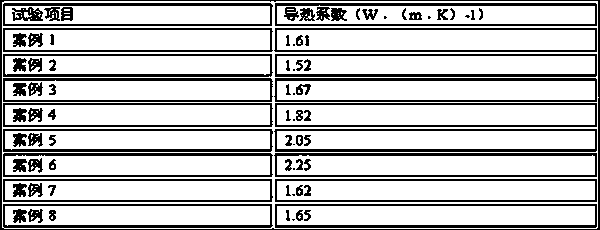

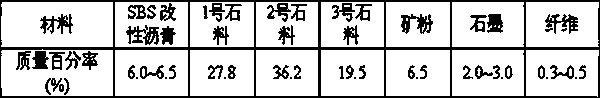

[0028] Table 3 Main properties of graphite

[0029]

[0030] Table 4 Synthesis gradation of SMA-13 mixture

[0031]

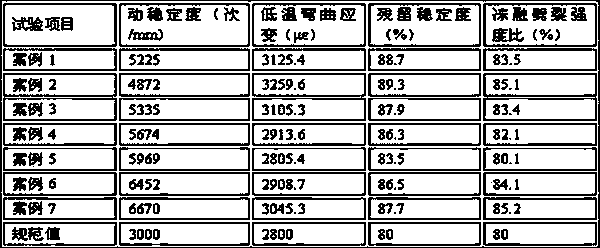

[0032] The p...

Embodiment example 2

[0034] The material and amount used in the heat-conducting SMA asphalt concrete in this implementation case are basically the same as those in Case 1, except that no graphite is added. The construction process is as follows: 1) Add fibers to the aggregate (aggregate in mineral aggregate) heated to 180°C~200°C, and stir for 10~15 seconds; 2) Add asphalt heated to 175°C to the mixture and mix 90 seconds; 3) Add mineral powder to the mixture, mix for 90-100 seconds, and then go through the molding process to make heat-conducting SMA asphalt concrete.

Embodiment example 3

[0036] The materials and dosage of the heat-conducting SMA asphalt concrete in this implementation case are the same as those in Case 1. The construction process is as follows: 1) Add fiber and graphite to the aggregate (aggregate in mineral aggregate) heated to 180°C~200°C, and stir 10~15 seconds. 2) Add the asphalt heated to 175°C into the mixture and stir for 90 seconds. 3) Add mineral powder to the mixture, mix again for 90-100 seconds, and then go through the molding process to obtain heat-conducting SMA asphalt concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com