Making method for high TG halogen-free LOW Dk/Df copper-clad plate

A manufacturing method and copper-clad laminate technology, applied in chemical instruments and methods, lamination auxiliary operations, lamination, etc., can solve problems such as unsuitable high-frequency circuit boards, achieve high glass transition temperature, low dielectric constant, The effect of good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below through specific embodiments.

[0024] The manufacturing method of the high TG halogen-free LOW Dk / Df copper clad laminate provided by the present invention includes the steps of: disposing glue liquid-gluing-lamination and hot pressing.

[0025] S1: Preparation of glue

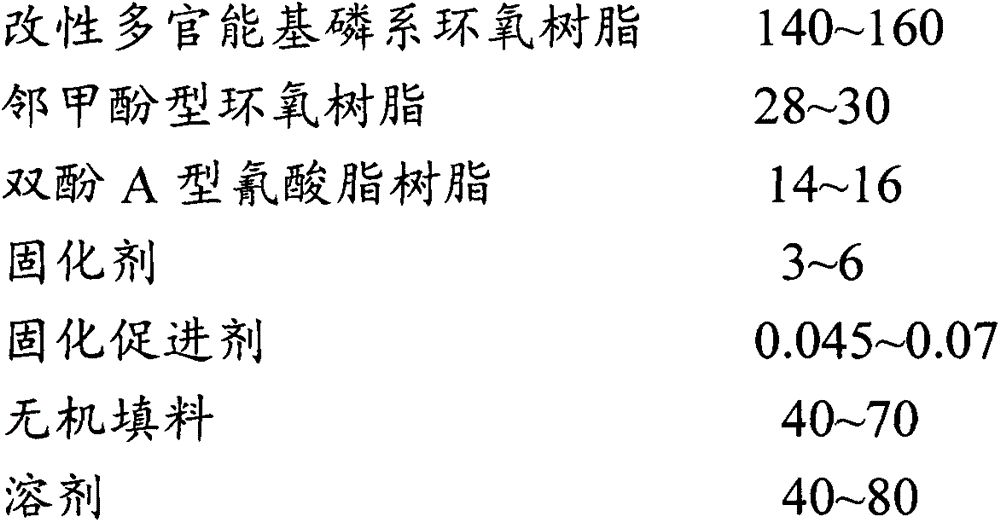

[0026] The glue composition includes (parts by weight):

[0027]

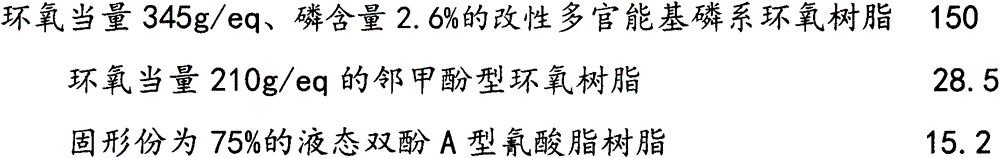

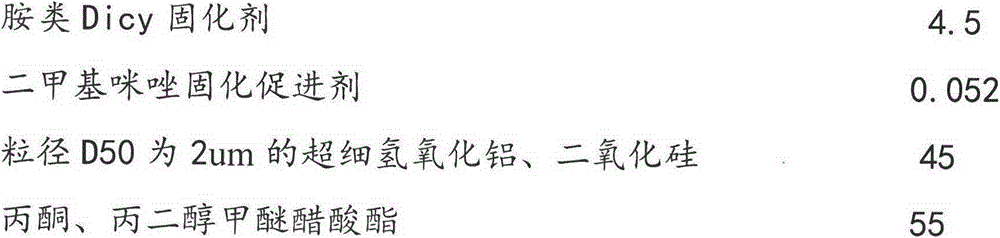

[0028]

[0029] The glue is prepared according to the above components, and the gel is evenly stirred, and the gel time is 288S;

[0030] The modified polyfunctional phosphorus-based epoxy resin with an epoxy equivalent of 345 g / eq and a phosphorus content of 2.6% is an epoxy resin modified by DOPO-based epoxy resin by adding a polyfunctional resin and a propanol phenol resin. The main features are: wide working window, high Tg value of the substrate made with it, good heat resistance and flame resistance, etc.;

[0031] Ortho-cresol type epoxy resin with epoxy equivalent of 210g / eq;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com