Circulating fluidized bed coal boiler denitration method

A circulating fluidized bed and coal-fired boiler technology, which is applied in the field of high-temperature flue gas denitrification system, can solve the problems of low denitrification efficiency, achieve high denitrification efficiency, simplify the denitrification process, and reduce the amount of ammonia escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

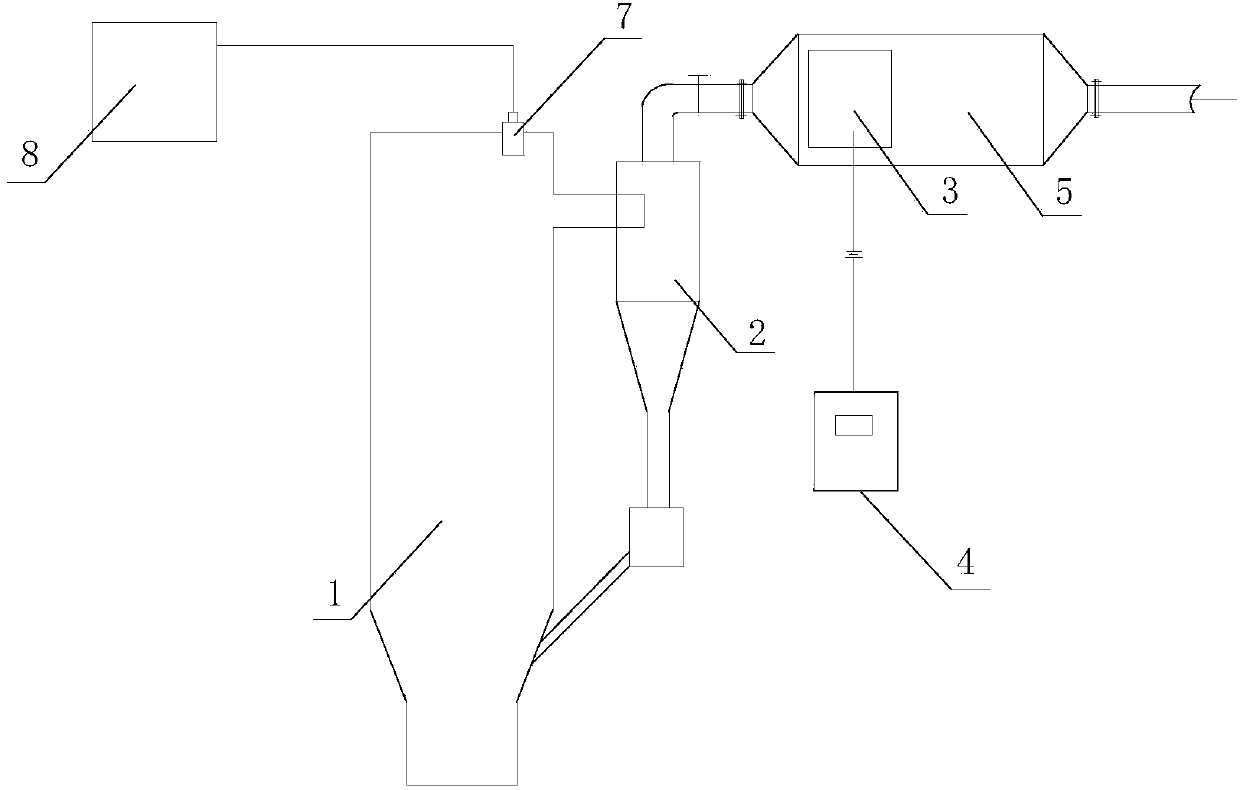

[0022] 1. A new denitration method for a circulating fluidized bed coal-fired boiler, comprising a coal-fired boiler 1, a cyclone separator 2, a corona-free electron emission cathode reactor 6, a liquid atomization spray gun 7, a liquid storage tank and a regulating valve 8 .

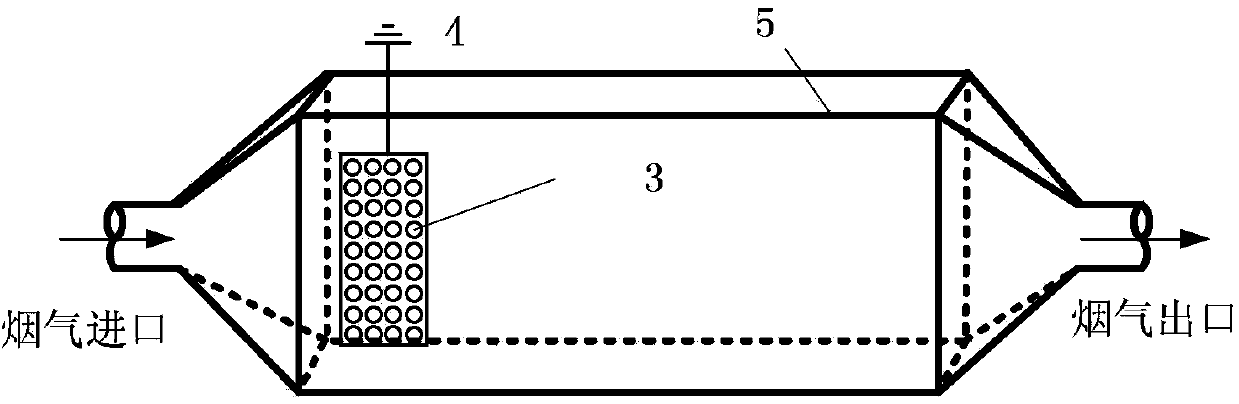

[0023] 2. The upper and lower parts of one side of the furnace 1 are respectively connected with one end of the horizontal flue and the return pipe, the other end of the horizontal flue is connected with the inlet 2 of the cyclone dust collector, and the upper and lower outlets of the cyclone separator 2 are respectively connected with the non-corona type electron emission The inlet pipe of the cathode 3 reactor is connected to one end of the return pipe, and there is no corona-type electron emission cathode reactor.

[0024] 3. Arrange a reducing agent injection device near the exit of the furnace 1 tail. The reducing agent is 8% to 15% ammonia solution.

[0025] 4. The ammonia solution flow control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com