Ozone/hydrogen peroxide-induced free radical flue gas purification method and system

A hydrogen peroxide and flue gas purification technology, applied in chemical instruments and methods, separation methods, applications, etc., can solve the problems of high application cost, high temperature self-decomposition of oxidants, and inability to remove them, and reduce initial investment and operation. effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

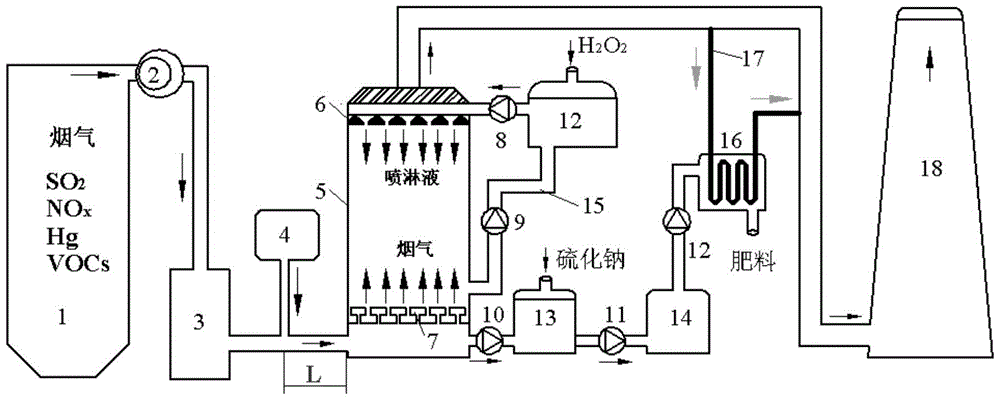

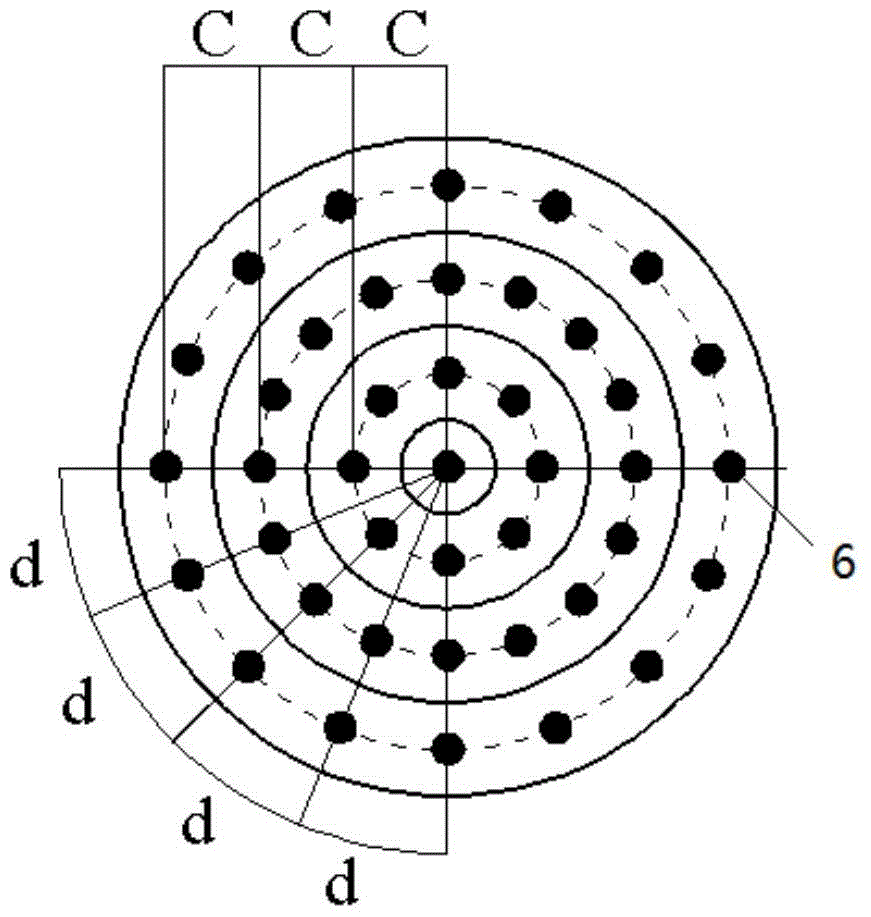

Method used

Image

Examples

Embodiment 1

[0057] Example 1. SO in flue gas 2 ﹑NO x ﹑Hg 0 and VOCs concentrations are 2000ppm, 400ppm, 50ug / m 3 and 100mg / m 3 , the flue gas temperature is 25°C, the hydrogen peroxide molar concentration is 1.0mol / L, the ozone injection concentration is 100ppm, and the liquid-gas ratio is 5L / m 3 , The ozone injection distance is 50cm. SO in flue gas 2 ﹑NO x ﹑Hg 0 The simultaneous removal efficiencies of VOCs and VOCs were 100%, 60.9%, 78.8% and 38.2%, respectively.

Embodiment 2

[0058] Example 2. SO in flue gas 2 ﹑NO x ﹑Hg 0 and VOCs concentrations are 2000ppm, 400ppm, 50ug / m 3 and 100mg / m 3 , the flue gas temperature is 25°C, the hydrogen peroxide molar concentration is 1.0mol / L, the ozone injection concentration is 100ppm, and the liquid-gas ratio is 10L / m 3 , The ozone injection distance is 50cm. SO in flue gas 2 ﹑NO x ﹑Hg 0 The simultaneous removal efficiencies of VOCs and VOCs were 100%, 68.9%, 85.7% and 48.6%, respectively.

Embodiment 3

[0059] Example 3. SO in flue gas 2 ﹑NO x ﹑Hg 0 and VOCs concentrations are 2000ppm, 400ppm, 50ug / m 3 and 50mg / m 3 , the flue gas temperature is 35°C, the hydrogen peroxide molar concentration is 1.5mol / L, the ozone injection concentration is 300ppm, and the liquid-gas ratio is 25L / m 3 , The ozone injection distance is 100cm. SO in flue gas 2 ﹑NO x ﹑Hg 0 The simultaneous removal efficiencies of VOCs and VOCs were 100%, 86.9%, 94.6% and 68.9%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com