A method for resource recycling of scum

A technology of resource utilization and scum, applied in the application, animal feed, additional food elements, etc., can solve the problems of not conforming to the fermented feed with clear fermentation strains, unclear strains of koji, restricting industrialization, etc., to achieve the realization of scum Harmless treatment and resource utilization, eliminating environmental pollution and nutrient waste, and creating economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

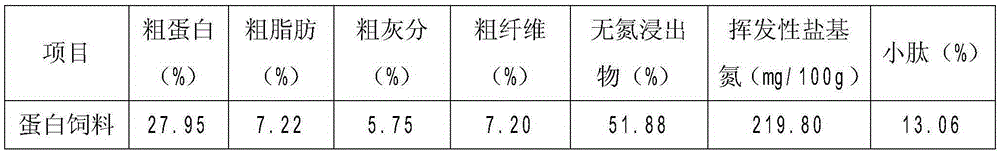

Image

Examples

Embodiment 1

[0021] 1. Cultivation of fermentation strains:

[0022] Bacillus licheniformis D-1 strain was selected as the fermentation strain, and the medium was beef extract peptone medium, and its formula was: beef extract 5.0 g / L, peptone 10.0 g / L, NaCl 5.0 g / L, and the pH was adjusted to 7.0.

[0023] Take 10mL of normal saline with a mass fraction of 0.9% in a test tube, sterilize at 121°C for 20 minutes, cool to 30°C, and pour all the freeze-dried powder of Bacillus licheniformis D-1 into the above-mentioned physiological saline under aseptic condition , shake to make it dissolve, put it in a 30°C incubator for 30 minutes for activation, and set aside;

[0024] Measure 200mL of beef extract peptone medium into a 500mL Erlenmeyer flask, sterilize at 121°C for 20 minutes, cool to 30°C, inoculate the above-mentioned activated strains according to 10% (volume fraction) of the medium volume, and place on a shaker at 30°C Cultivate for 24 hours, and the shaking table rotates at 120-130 r...

Embodiment 2

[0033] In step (1) of this embodiment, the mass ratio of scum and wheat bran is 1:1, and the mass percentage of the overall water content is controlled at about 50%; in step (2), the initial fermentation temperature is 25°C; In step (3), the drying temperature of the wet material is 40° C., and other steps are the same as in Example 1.

Embodiment 3

[0035] In step (1) of this embodiment, the mass ratio of scum and wheat bran mixed is 2:1, and the mass percentage of overall water content control is about 60%; in step (2), the initial fermentation temperature is 30°C; In step (3), the drying temperature of the wet material is 45° C., and other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com