A nano-modified water-based multifunctional sound-absorbing coating and its preparation method

A nano-modified and sound-absorbing coating technology, applied in the coating and other directions, can solve the problems of affecting the drying speed of the coating, difficult to separate asbestos, complicated construction and use, etc., and achieve the effects of superior thermal insulation performance, low density and low hygroscopicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

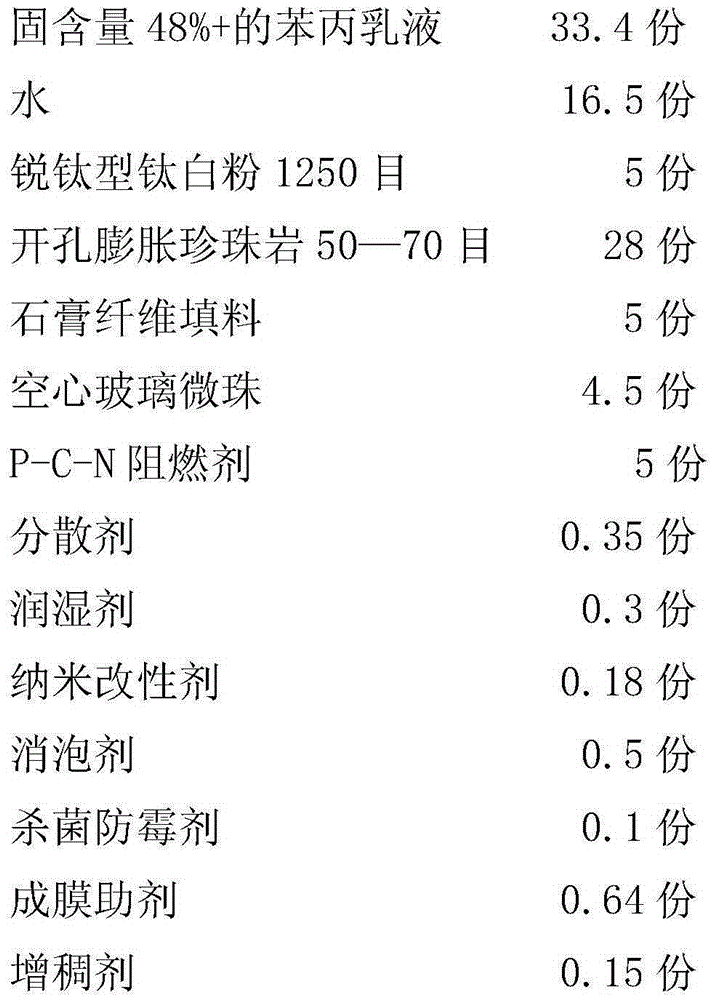

[0031] Ingredients as follows:

[0032]

[0033]

[0034] 100 parts by weight

[0035] The preparation method is as follows:

[0036] 1. Put the formulated amount of emulsion, half of the dispersant, wetting agent, one-third of the defoamer and all the bactericide and antifungal agent into the dispersing and stirring equipment, and disperse and stir at a speed of 300r / min-500r / min 10-15 minutes, slowly add all the nano-modifiers, continue to disperse and stir at a speed of 600r / min-1000r / min, and slowly add a pH regulator to make the pH of the system 8-9, disperse and stir for 20-30 Minutes, modified emulsion A was prepared.

[0037] 2. Take half of the formula amount of water, add one-third of the defoamer, the remaining dispersant, and wetting agent at a speed of 300-500r / min, disperse and stir for 10-15 minutes, and sieve in all the pigments and flame retardants , gradually increase the rotation speed to 1200r / min-1500r / min, disperse at high speed for 20-30 minutes; ...

Embodiment 2

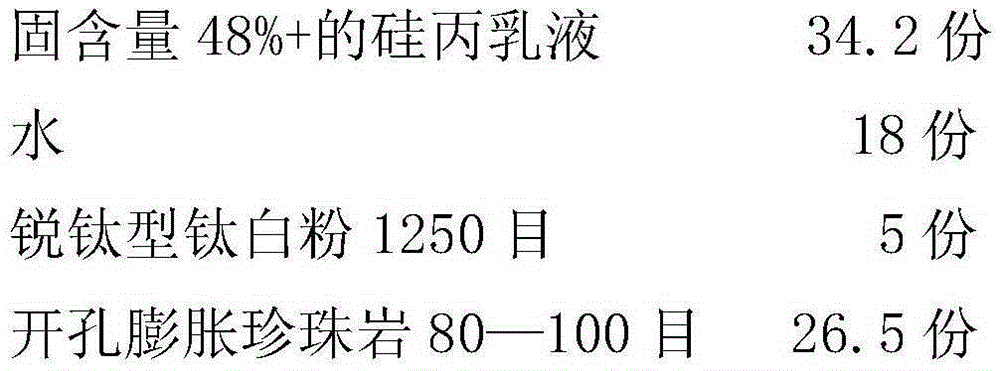

[0041] Ingredients as follows:

[0042]

[0043]

[0044] 100 parts by mass

[0045] Preparation method is the same as embodiment one

[0046] The finished product has low specific gravity, superior mechanical properties, and excellent heat preservation, moisture-proof, fire-proof, aging resistance, anti-fouling, sterilization, air purification and other effects.

[0047] According to the standard requirements of GB / T20247-2006 "Acoustic Reverberation Room Sound Absorption Measurement", the measured sound absorption coefficient of this product is 0.65.

Embodiment 3

[0049] Ingredients as follows:

[0050]

[0051]

[0052] 100 parts by mass

[0053] Preparation method is the same as embodiment 1

[0054] The finished product has excellent water resistance, weather resistance, oil resistance and other properties, and also has excellent mechanical properties, and also has high-value properties such as environmental protection, heat preservation, aging resistance, fire prevention, sterilization, and air purification.

[0055] According to the standard requirements of GB / T20247-2006 "Acoustic Reverberation Room Sound Absorption Measurement", the measured sound absorption coefficient of this product is 0.80.

[0056] The nano-material for modifying the polymer base material is nano-silica coated with nano-titanium dioxide on the surface according to the method of Chinese invention patent ZL200910063398.2, and a composite nano-material with nano-silica surface-coated with nano-titanium dioxide is used. At the same time, the material has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com