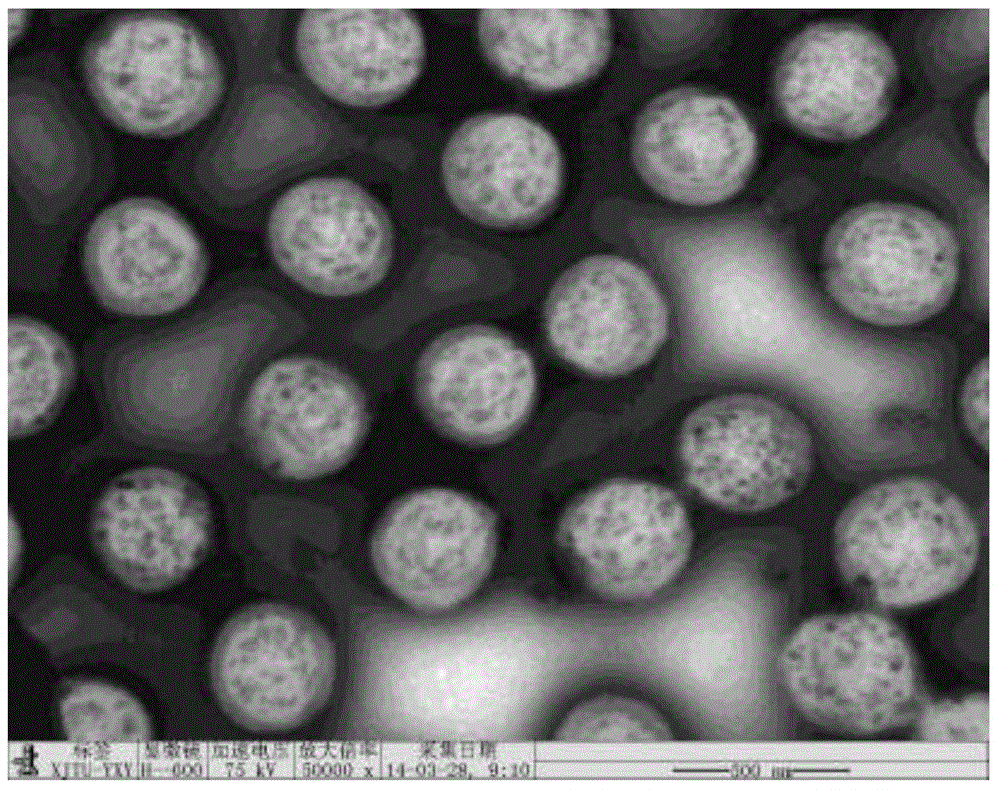

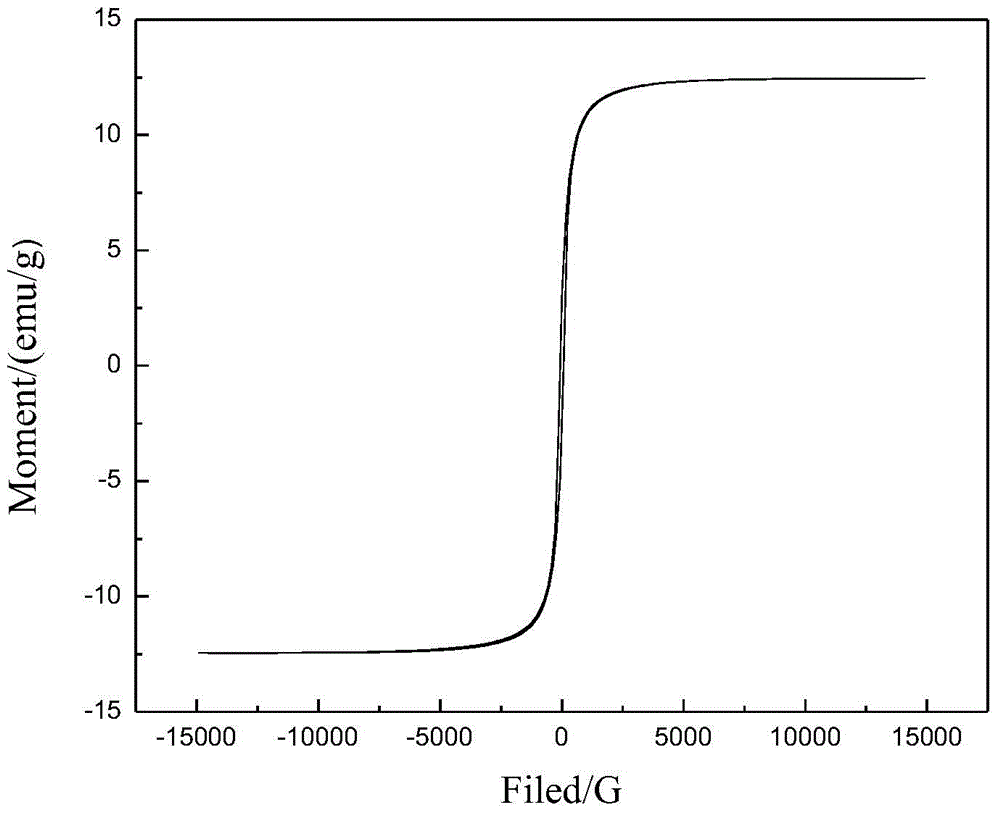

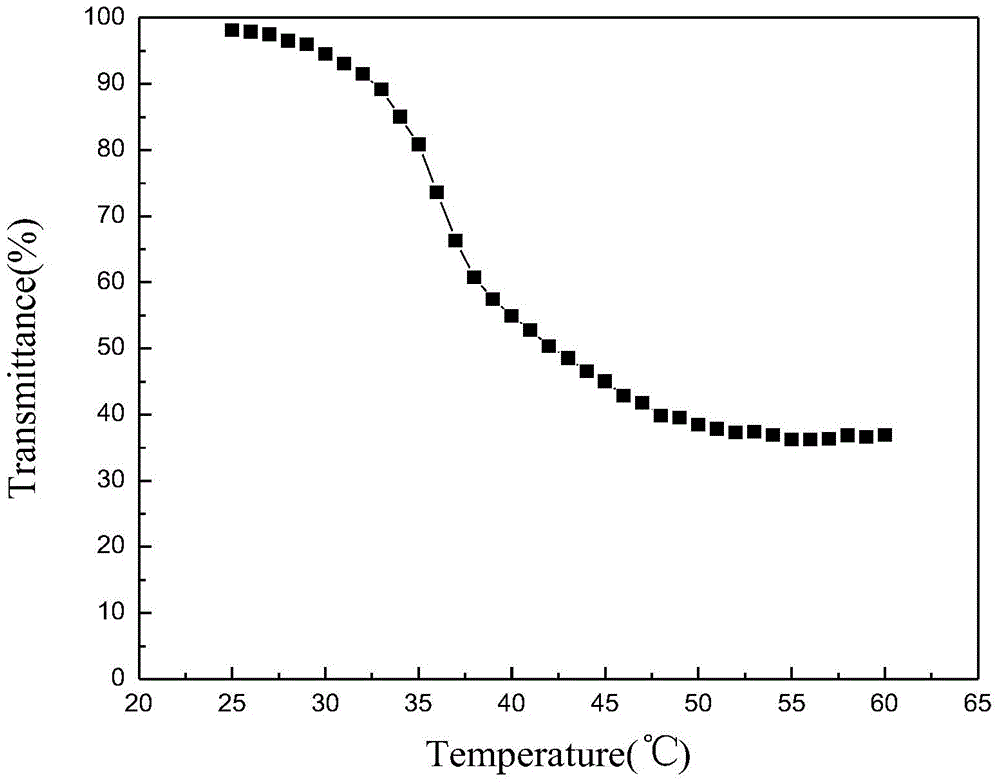

Preparation method of poly(N-isopropylacrylamide-methacrylic acid) porous microspheres with magnetic field and temperature dual responsiveness

A technology of isopropylacrylamide and methacrylic acid is applied in the field of preparation of polyporous microspheres, which can solve the problems of poor monodispersity of microspheres and narrow application range, and achieve controlled release of biomedicine and magnetic targeting. The effect of convenient medicine, sensitive temperature responsiveness, and few steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The technical scheme adopted by the present invention to solve its technical problems: the preparation method of poly(N-isopropylacrylamide-methacrylic acid) porous microspheres with dual responsiveness to magnetic field and temperature, which is characterized by comprising the following steps.

[0024] (1) Prepare a mixed aqueous solution of N-isopropylacrylamide with a concentration of 6.7-6.8g / L and N,N'-methylenebisacrylamide with a concentration of 0.5-0.8g / L, and add methyl The acrylic acid monomer is added in a proportion of 7.0-9.0% of the weight of the N-isopropylacrylamide monomer in the solution.

[0025] (2) Transfer the solution prepared in step (1) into a three-necked flask and heat it to 70°C under the condition of an oil bath or water bath, and at the same time pass nitrogen into it, and then inject N-isopropylacrylamide into the solution with a mass of 2.3~ 3.0% of the initiator, started to initiate the polymerization reaction.

[0026] (3) The initiat...

Embodiment 1

[0033] Example 1: Add 0.3397g of N-isopropylacrylamide and 0.0251g of N,N'-methylenebisacrylamide into 50mL of pure water, and add 25μL of methacrylic acid to it after fully dissolving. Pour the mixed solution into a 100mL three-neck flask, place it in an oil bath at 70°C for magnetic stirring, and at the same time pass through nitrogen gas. After 20 minutes, add 3 mL of ammonium persulfate aqueous solution with a concentration of 2.5 mg / mL to the solution with a syringe, and wait for 3 to 5 minutes. The solution appeared light blue, and the nitrogen reaction was continued for 12h. After the reaction, stir and cool to room temperature, adjust the pH value of the solution to 10.00 with 1:1 diluted ammonia water under pH meter monitoring and magnetic stirring, stir at room temperature for 4h, then use 1:1 under pH meter monitoring and magnetic stirring 1 diluted hydrochloric acid to adjust the pH value of the solution to 2.50, sealed and stirred for 4h. Then put the sample into...

Embodiment 2

[0036] Example 2: Add 0.7000g of N-isopropylacrylamide and 0.0800g of N,N'-methylenebisacrylamide into 100mL of pure water, and add 52μL of methacrylic acid to it after fully dissolving Pour the mixed solution into a 250mL three-neck flask, place it in an oil bath at 70°C for magnetic stirring, and at the same time pass through nitrogen gas. After 20 minutes, add 6 mL of ammonium persulfate aqueous solution with a concentration of 3 mg / mL to the solution with a syringe, and wait for 3 to 5 minutes. Appear light blue, continue nitrogen reaction 10h. After the reaction is over, stir and cool to room temperature, adjust the pH value of the solution to 9.90 with 1:1 diluted ammonia water under pH meter monitoring and magnetic stirring, stir at room temperature for 3h, then use 1:1 under pH meter monitoring and magnetic stirring 1 diluted hydrochloric acid to adjust the pH value of the solution to 2.00, sealed and stirred for 3h. Then put the sample into a dialysis bag with a mole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com