Preparation method of carbon fiber/sulfur composite positive material with multilevel structure

A composite cathode material and carbon fiber technology, applied in structural parts, battery electrodes, electrical components, etc., can solve problems such as poor electrochemical performance, achieve the effects of improving electrical conductivity, reducing graphitization temperature, and reducing raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

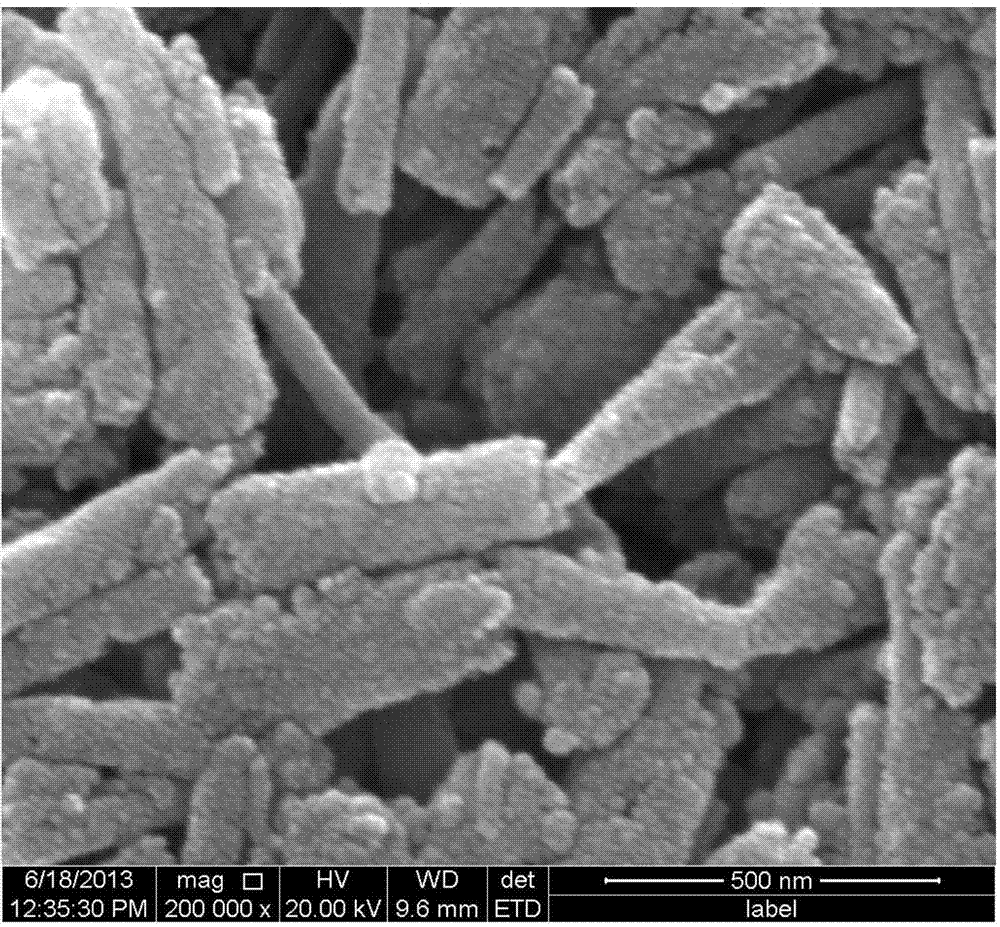

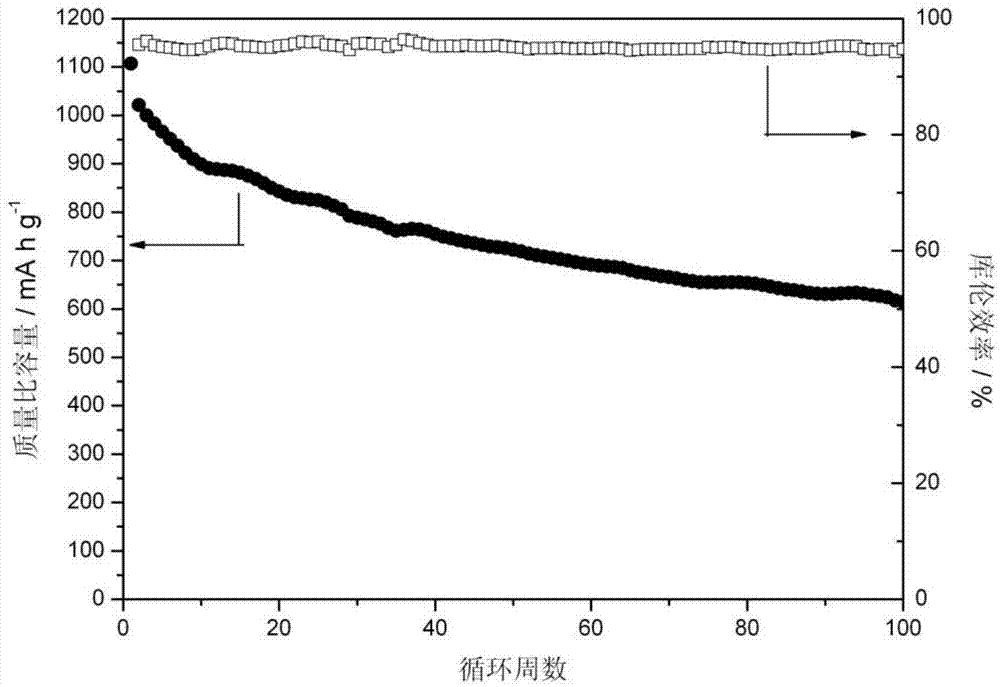

[0028] A method for preparing a multi-level structure carbon fiber / sulfur composite positive electrode material, the specific steps are:

[0029] 1) Dissolve 1 g of nickel nitrate and 1 g of polyacrylonitrile powder (number average molecular weight 150,000) in 10 g of N, N-dimethylformamide, and mix well to obtain a solution;

[0030] 2) Put the solution obtained in step 1) in the injector of the electrospinning apparatus, apply a high voltage of 20kV, and inject the solution at a speed of 0.1mm·min -1 ;

[0031] 3) moving the metal salt-containing film obtained in step 2) to a muffle furnace, and calcining in air at 250° C. for 2 hours to obtain a pre-oxidized film;

[0032] 4) Move the pre-oxidized film obtained in the step into a tube furnace, feed argon gas, and calcinate at 1600°C for 0.5h, and obtain a carbon fiber film containing metal salt after the reaction is completed;

[0033] 5) After the reaction is over, the carbon fiber film containing metal salt obtained in ...

Embodiment 2

[0038] A method for preparing a multi-level structure carbon fiber / sulfur composite positive electrode material, the specific steps are:

[0039] 1) Dissolve 0.1g of ferric nitrate and 3g of polyvinylpyrrolidone powder (number average molecular weight 1,300,000) in 10g of water, mix well to obtain a solution;

[0040] 2) Place the solution obtained in step 1) in the injector of the electrospinning apparatus, apply a high voltage of 12kV, and inject at a speed of 0.01mm·min -1 ;

[0041]3) moving the metal salt-containing film obtained in step 2) to a muffle furnace, and calcining in air at 100° C. for 4 hours to obtain a pre-oxidized film;

[0042] 4) Move the pre-oxidized film obtained in the step into a tube furnace, feed argon gas, and calcinate at 800° C. for 3 hours, and obtain a carbon fiber film containing metal salt after the reaction is completed;

[0043] 5) After the reaction is over, the carbon fiber film containing metal salt obtained in step 4) is added to 6mol...

Embodiment 3

[0048] A method for preparing a multi-level structure carbon fiber / sulfur composite positive electrode material, the specific steps are:

[0049] 1) Dissolve 1.5g of nickel acetate and 0.5g of polyethylene glycol powder (number average molecular weight: 1,000,000) in 10g of water, mix well to obtain a solution;

[0050] 2) Place the solution obtained in step 1) in the injector of the electrospinning apparatus, apply a high voltage of 25kV, and inject the solution at a speed of 0.2mm·min -1 ;

[0051] 3) moving the metal salt-containing film obtained in step 2) to a muffle furnace, and calcining in air at 300° C. for 0.5 h to obtain a pre-oxidized film;

[0052] 4) Move the pre-oxidized film obtained in the step into a tube furnace, feed argon gas, and calcinate at 600° C. for 6 hours, and obtain a carbon fiber film containing metal salt after the reaction is completed;

[0053] 5) After the reaction is over, the carbon fiber film containing metal salt obtained in step 4) is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com