Positive electrode of all-solid-state lithium battery and manufacturing method thereof, and all-solid-state lithium battery

A production method and all-solid-state technology, applied in electrode manufacturing, battery electrodes, lithium batteries, etc., can solve the problems of small contact area and large internal resistance, improve contact area, reduce battery internal resistance, and increase energy density and rate performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

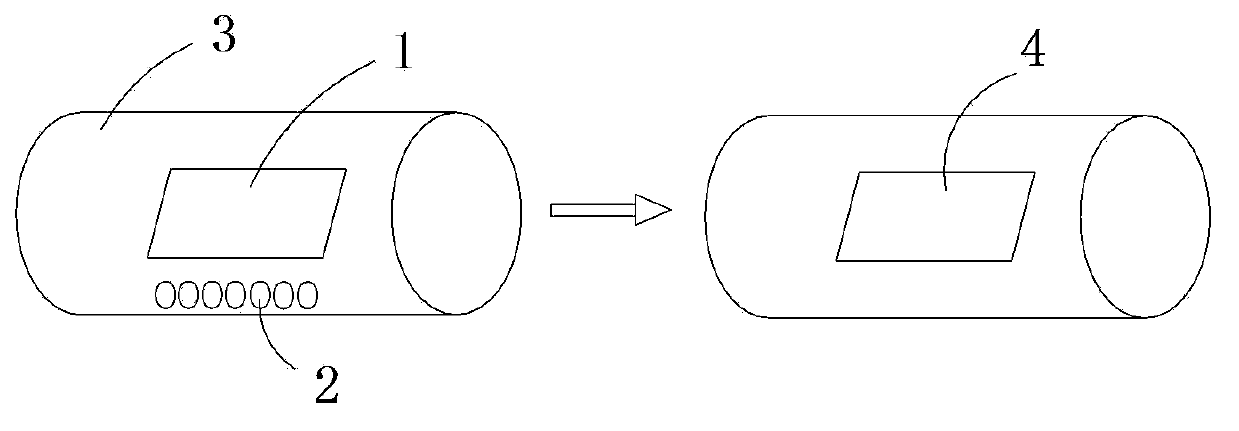

Method used

Image

Examples

Embodiment 1

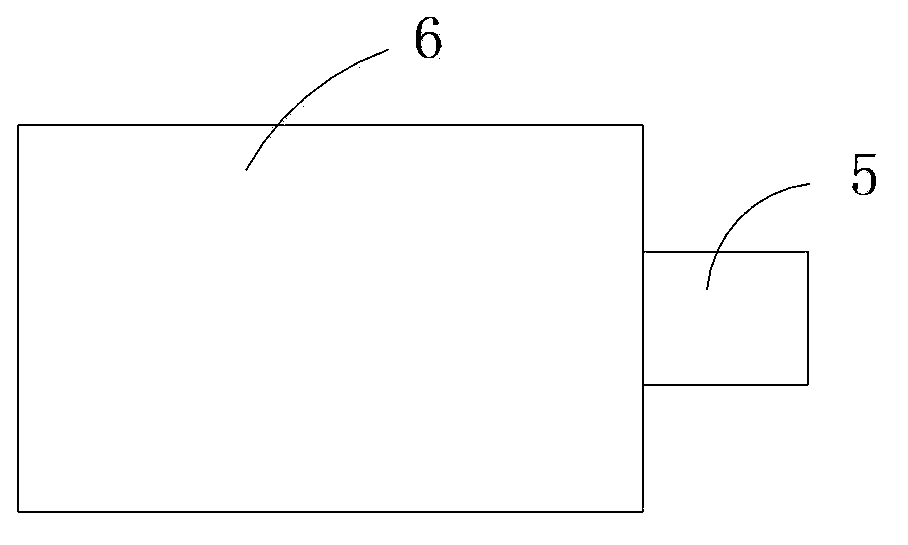

[0043] Choose lithium cobalt oxide: 70Li 2 S.30P 2 S 5 Glass-ceramic (glass-ceramic) electrolyte: Vapor-grown carbon fiber is mixed according to the mass ratio of 70:25:5 and mixed evenly in a planetary ball mill under the protection of argon, and then pressed into a thickness of about 150 μm under a hot press After completion, place the thin slice in a quartz seal tube with sulfur (S) element at the bottom and vacuum seal it, then keep the seal tube at 400°C~450°C for 6 hours (h), and then slowly cool it down. Then, the active pole piece filled with S simple substance was adhered to the aluminum current collector coated with PVDF conductive glue on the surface, and cold pressed and dried to obtain the positive pole piece.

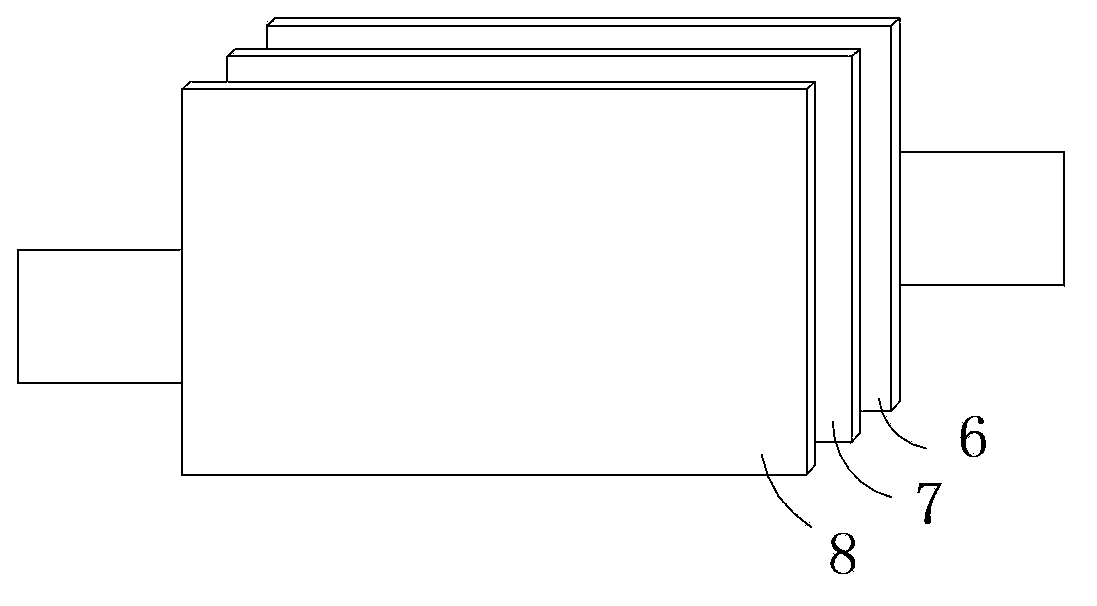

[0044] Add the pressed glass-ceramic electrolyte sheet with a thickness of 100μm to the side of the positive electrode sheet close to the active electrode, and go through 360MPa hot pressing or cold pressing to make the two tightly connected together, an...

Embodiment 2

[0046] Choose lithium cobalt oxide: 70Li 2 S.30P 2 S 5 Glass-ceramic electrolyte: Vapor-grown carbon fiber is mixed according to the mass ratio of 70:25:5 and mixed evenly in a planetary ball mill under the protection of argon, and then pressed into a thin sheet with a thickness of about 150 μm under a hot press. Place this flake on the bottom with GeS 2 Put the simple substance in a sealed quartz tube and vacuum seal it, then keep the sealed tube at 600~650°C for 6h, and then cool it down slowly. This is then populated with GeS 2 The simple active pole piece is adhered to the aluminum current collector coated with PVDF conductive glue on the surface, and cold-pressed and dried to obtain the positive pole piece.

[0047] Add the pressed glass-ceramic electrolyte sheet with a thickness of 100μm to the side of the positive electrode sheet close to the active electrode, and go through 360MPa hot pressing or cold pressing to make the two tightly connected together, and then pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com