Method for preparing high-orientation small organic molecule semiconductor single-crystal patterns with controllable sizes

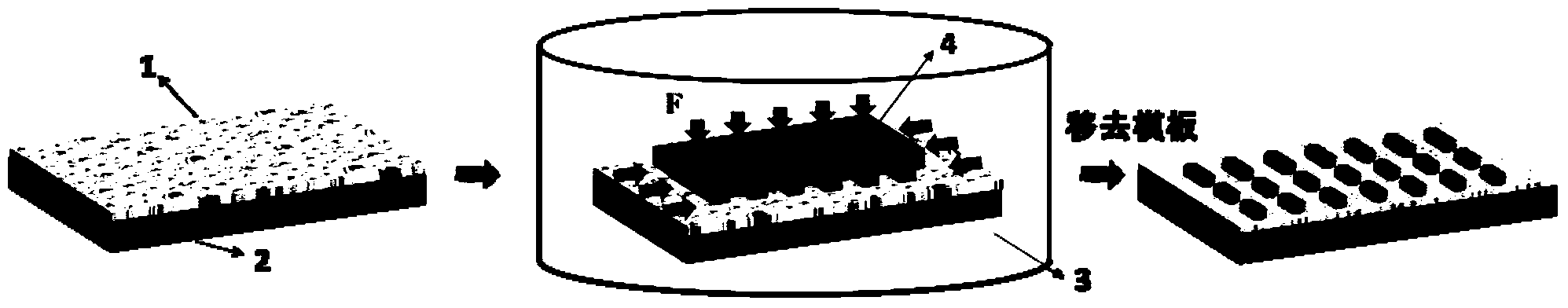

A technology of small molecules and semiconductors, which is applied in the field of preparing large-area, high-orientation and size-controllable organic small molecule semiconductor single crystal patterns, which can solve the problems of complex processing technology and difficulty in mass production, and achieve simplified processing technology, The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: The preparation of highly oriented anthracene stripe single crystal patterns with controllable large-area size, the steps are as follows:

[0036] The first step is to perform anti-sticking treatment on the silicon template. The silicon template was subjected to deionized water, acetone, ethanol, ultrasonic cleaning for 5 minutes, and oxygen plasma treatment for 2 minutes. Then place the silicon template in a desiccator filled with vapor of perfluorododecyltrichlorosilane (1H,1H,2H,2H-Perfluorodecyltrichlorosilane) and heat it at 90°C for 4h, and take it out for use. As the silicon template, 12 μm, 22 μm, 32 μm, and 52 μm stripe templates with equal intervals are selected.

[0037] In the second step, a 7% (mass percent) tetrahydrofuran mixed solution of anthracene / PMMA is configured, wherein the mass ratio of anthracene to PMMA is anthracene:PMMA=1:1, and the solution is left for 24 hours to fully dissolve. The silicon substrate was ultrasonically cleane...

Embodiment 2

[0040] Example 2: The preparation of high-orientation TIPS-PEN stripe single crystal pattern with large area and size controllable, the steps are as follows:

[0041] The first step is to perform anti-sticking treatment on the 5μm, 15μm, 22μm, 32μm, 52μm striped silicon templates with equal spacing. The silicon template was ultrasonically cleaned with deionized water, acetone and ethanol for 5 minutes, and treated with oxygen plasma for 2 minutes. Then place the silicon template in a desiccator filled with perfluorododecyltrichlorosilane (1H,1H,2H,2H-Perfluorodecyltrichlorosilane) and heat it at 90°C for 4h, and take it out for use.

[0042] In the second step, a 4% (mass percentage) mixed solution of TIPS-PEN / PS in chloroform was prepared (TIPS-PEN:PS=1:1, mass ratio), and left for 24 hours to fully dissolve the solution. The glass substrate was ultrasonically cleaned for 5 minutes as follows: ultrasonically cleaned with deionized water, acetone and ethanol, and finally tr...

Embodiment 3

[0045] Example 3: The preparation of high-orientation TIPS-PEN stripe single crystal pattern with large area and size controllable, the steps are as follows:

[0046] Prepare 1%, 2%, 3%, and 4% TIPS-PEN / PS mixed solutions respectively, and prepare mixed films by drop coating, and treat the samples in saturated toluene organic vapor at 60°C for 10 hours, and the remaining steps are the same as Example 2 is the same.

[0047] The test results show that TIPS-PEN single crystal patterns with a width of 5 μm, 15 μm, 22 μm, 32 μm and 52 μm can be prepared with large area and high orientation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com