Electroluminescent device and display

A technology of electric field luminescence and components, which is applied in the direction of electrical components, electroluminescent light sources, electric light sources, etc., can solve the problems of high cost of driving circuits, strong charge repulsion, etc., and achieve high brightness luminous efficiency, low voltage drive, and high luminous efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

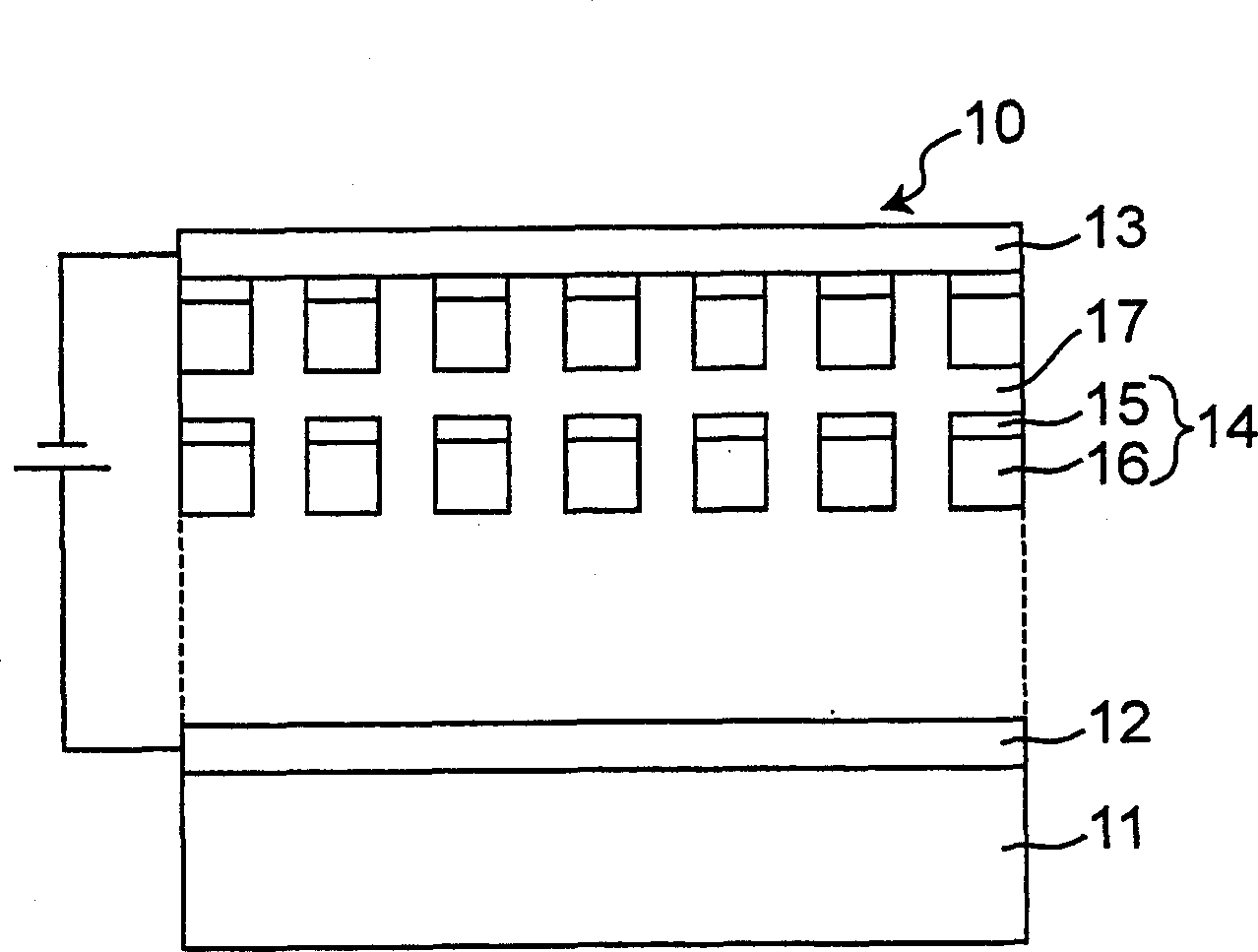

[0047] control figure 1 The electroluminescence element related to Embodiment 1 of the present invention will be described. figure 1 This is a cross-sectional view illustrating the structure of the electroluminescent element 10 according to the first embodiment. The electroluminescent device 10 has a multilayer structure, and has a pair of anode electrodes 12 and cathode electrodes 13 facing each other on a substrate 11 . In addition, between the anode electrode 12 and the cathode electrode 13 , a light emitting layer 14 composed of a semiconductor layer 15 and a phosphor layer 16 is repeatedly laminated via a transparent conductor layer 17 . The semiconductor layer 15 and phosphor layer 16 constituting the light emitting layer 14 are discontinuous layers, and the discontinuous portions between the light emitting layers 14 are filled with the transparent conductor layer 17 . in addition, figure 1 The middle light emitting layer 14 shows only two sets, but it is not limit...

Embodiment approach 2

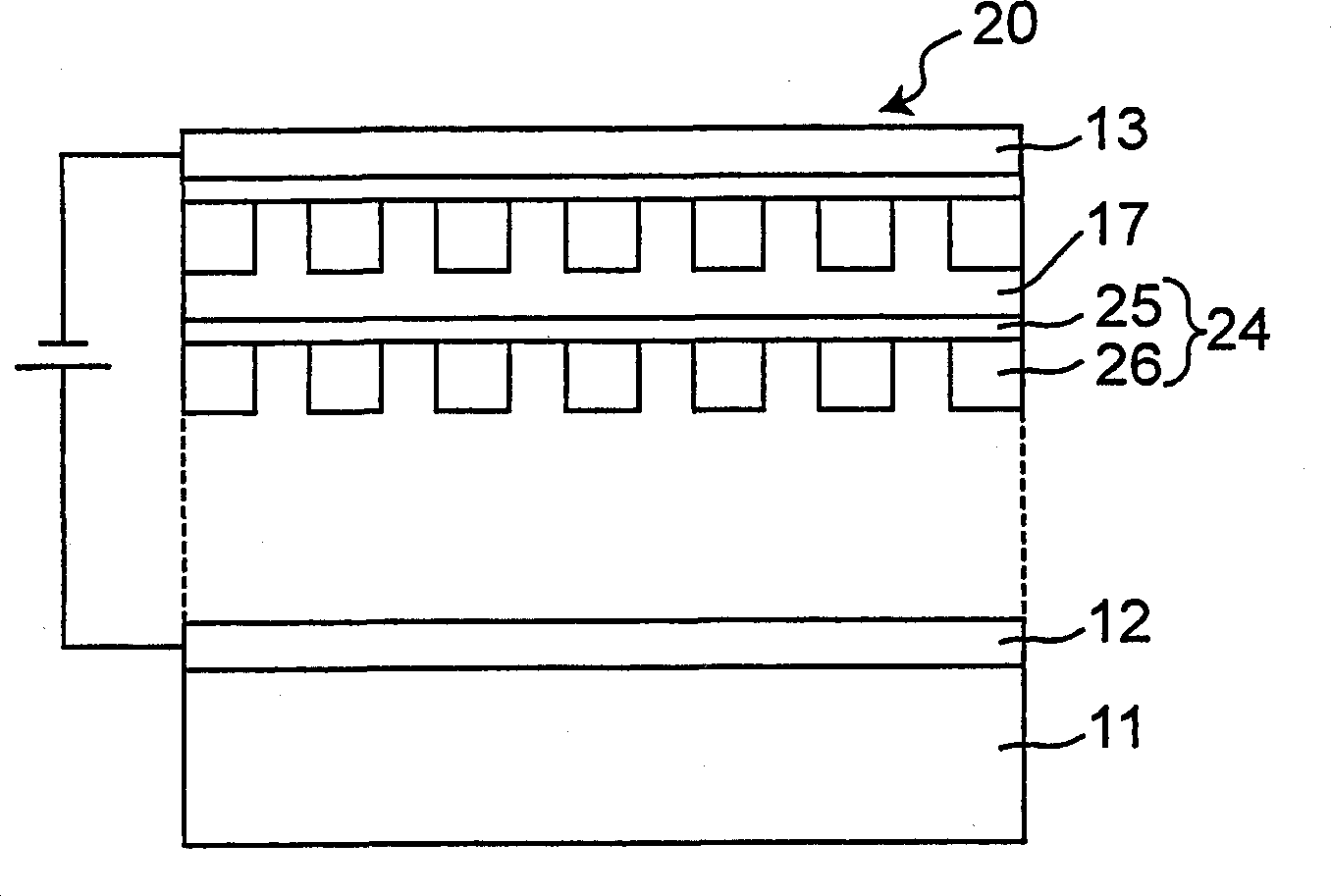

[0056] control figure 2 The related electroluminescent element 20 according to Embodiment 2 of the present invention will be described. This electroluminescent element 20 differs from the related electroluminescent element of Embodiment 1 in that the semiconductor layer 25 constituting the light emitting layer 24 with a large energy band gap is a continuous layer.

Embodiment approach 3

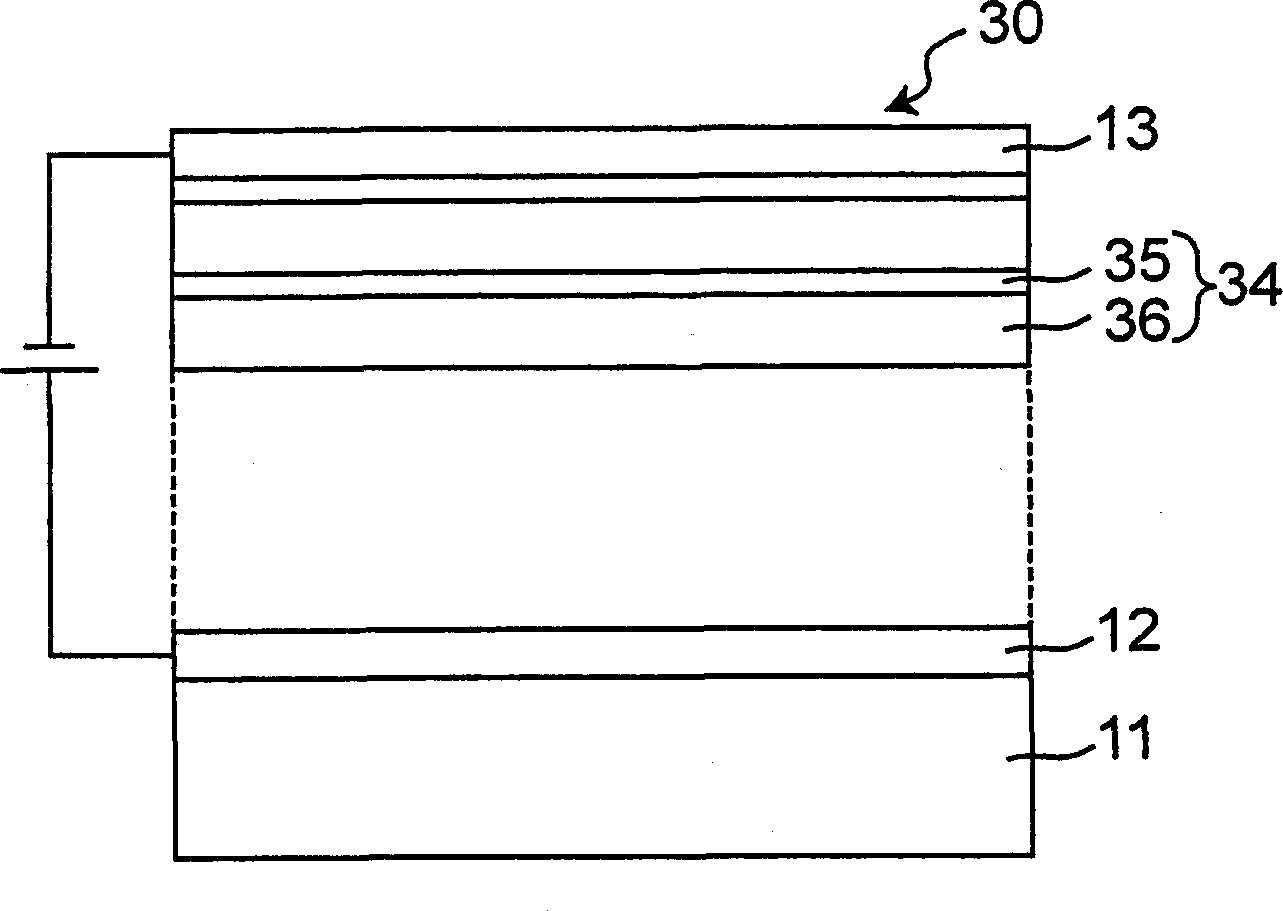

[0058] control image 3 The related electroluminescent element 30 according to Embodiment 3 of the present invention will be described. This electroluminescent element 30 differs from the related electroluminescent element of Embodiment 1 in that the semiconductor layer 35 and the phosphor layer 36 constituting the light emitting layer 34 with a large band gap are both continuous layers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com