Failure correlativity dynamic change analysis method of numerically-controlled machine tool

A technology of correlation relationship and analysis method, which is applied in the field of dynamic change analysis of the correlation relationship of CNC machine tool faults, and can solve problems such as the degree of correlation of intricate multi-systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0159] The present invention takes the complex correlation analysis among the three subsystems of the CNC machine tool as an example.

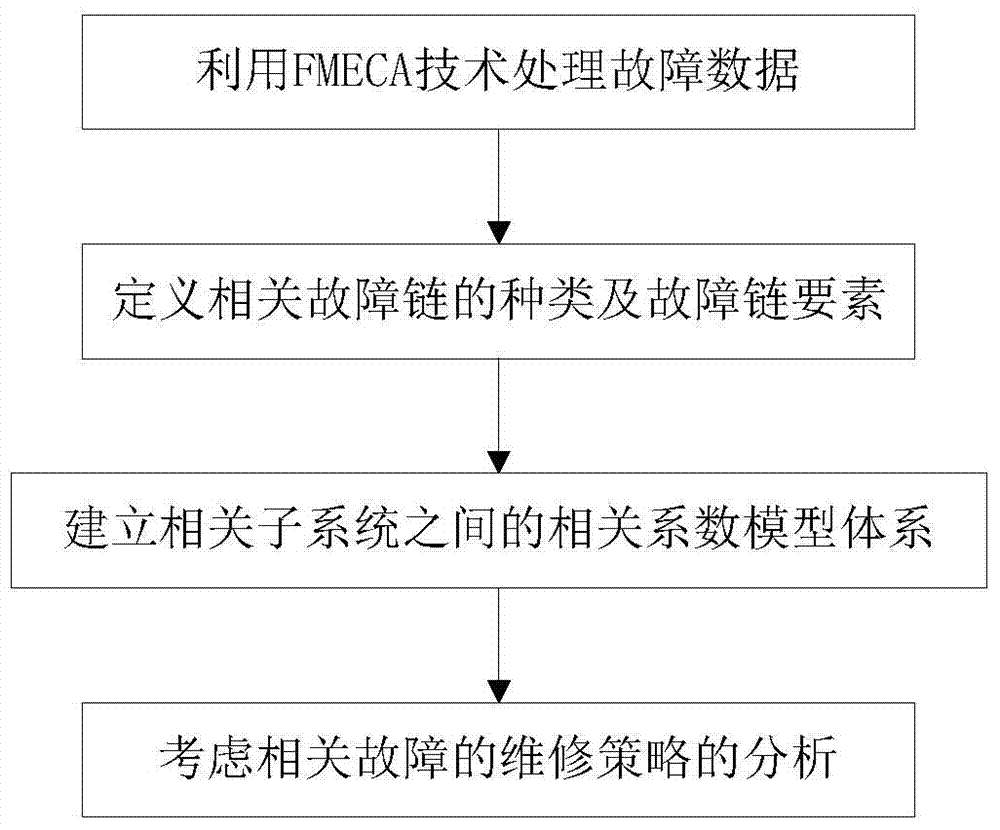

[0160] Step 1: Use FMECA analysis technology to process the fault data, divide the fault parts of each subsystem of the machine tool, and sort out the data with related faults.

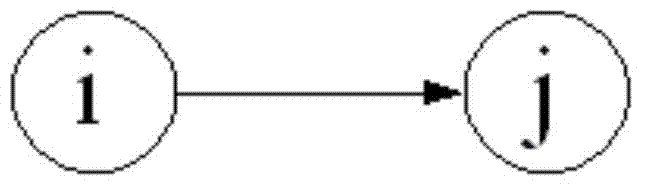

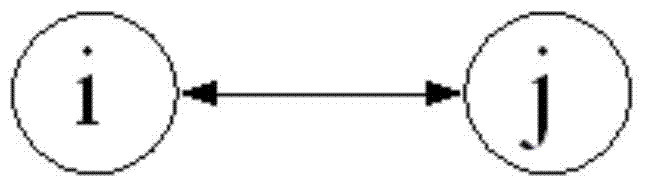

[0161] The data comes from the 13-month production failure tracking records of 175 machine tools of the same model. After processing the fault data through FMECA analysis technology, find out the subsystems with correlation, refer to Figure 7 relation as an example.

[0162] After processing by FMECA method, the failure time points and related failure time points of each subsystem are obtained. The failure interval time value is calculated from the failure time points as the failure data. The daily working system of the machine tool is two shifts. Table 1 shows the data of the tool holder system process result. Its calculation formula is as follows:

[0163] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com