Characterization method for distinguishing multi-phase sinter in hot-rolled silicon steel

A technology of iron oxide scale and silicon steel, which is applied in the direction of analyzing materials, using wave/particle radiation for material analysis, measuring devices, etc., can solve the problems of low efficiency, long time consumption, and inability to distinguish iron oxide scale objects, and achieve high experimental efficiency , Solve the effect that is difficult to identify and the analysis result is accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

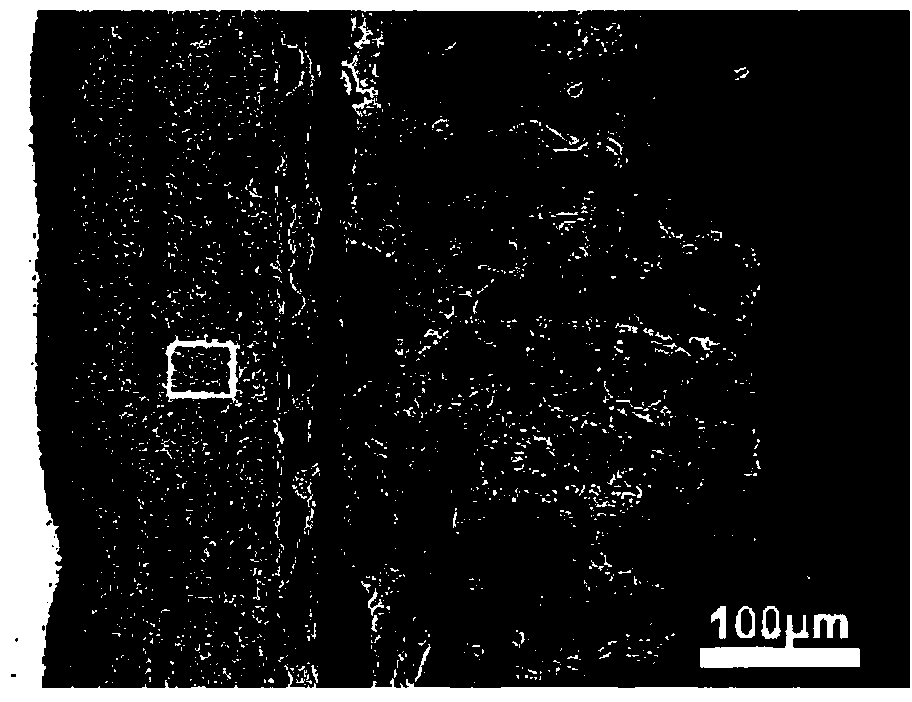

[0020] 1) The sample is cold-mounted in the longitudinal section, and the 220# grinding disc is used for rough grinding with a fully automatic grinding and polishing machine, and then polished with 9μm, 3μm and 1μm diamonds. The polishing time is 5min, 5min and 5min respectively. 0.02μm alumina polishing agent, the polishing time is about 3min, until no obvious scratches can be observed on the surface of the sample under the metallographic microscope at 50-100 times, the polished sample is quickly washed in absolute ethanol, and blown with a hair dryer dry with hot air;

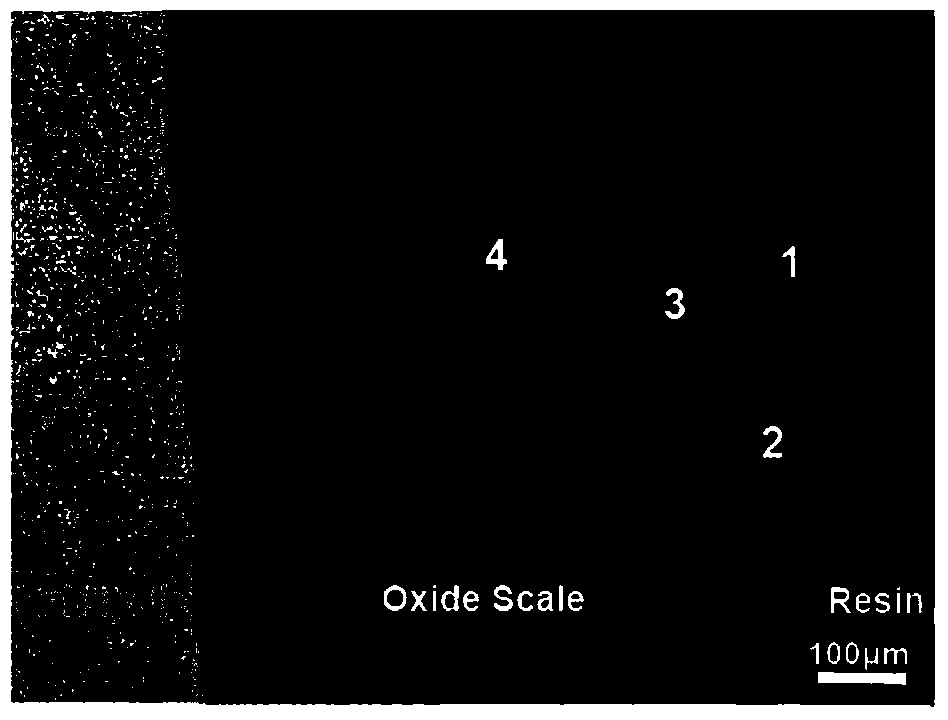

[0021] 2) Observing the microstructure of the iron oxide scale on the sample through the Shimadzu EPMA-1610 electronic probe, and using the state analysis function to collect data on the sample;

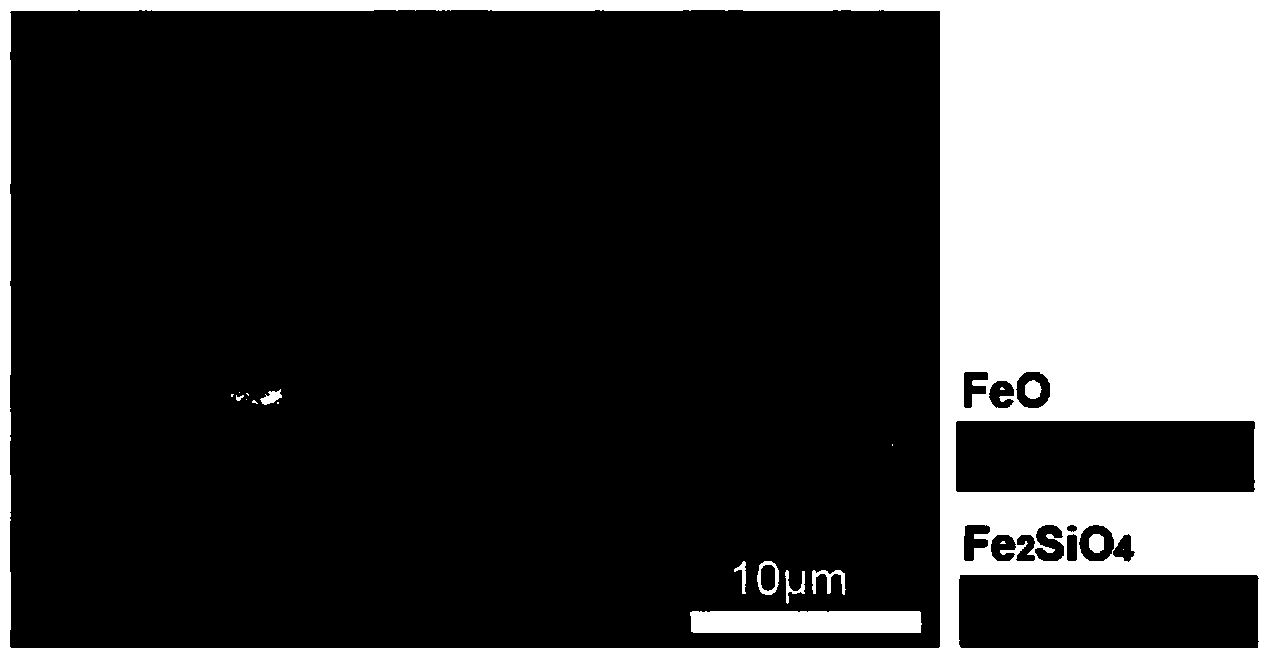

[0022] 3) The parameters set when the electronic probe collects the standard sample and the sample information to be tested are the same as follows: the accelerating voltage is 15kV, the current is 100nA, the beam s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com