Self-assembling method for preparing fibroin microspheres

A self-assembly, silk fibroin technology, which is applied in the preparation methods of peptides, chemical instruments and methods, animal/human peptides, etc. Structural features, simple preparation process, and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

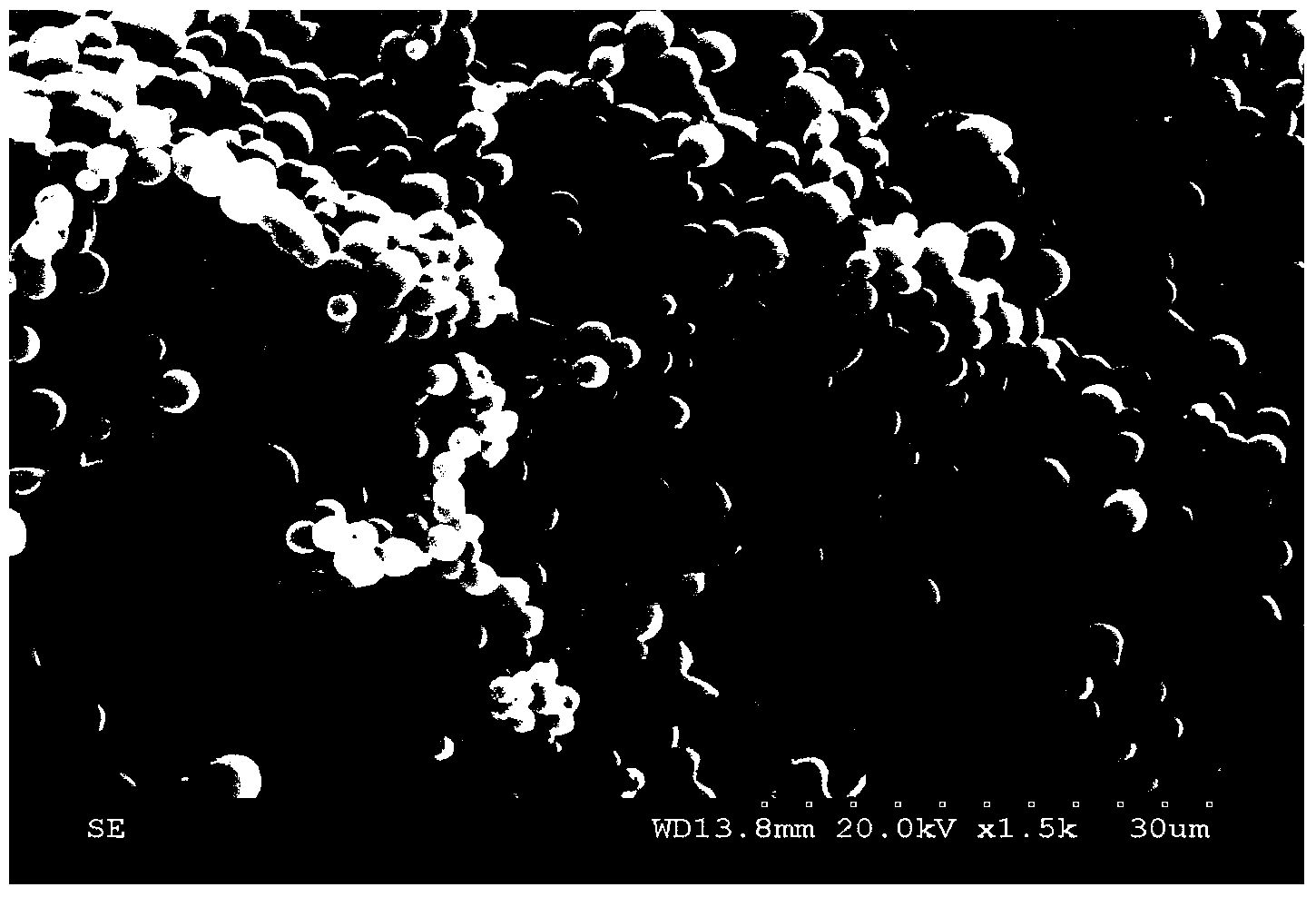

Image

Examples

Embodiment 1

[0026] The preparation method of silk fibroin microspheres in this embodiment includes the following steps in sequence.

[0027] (1) Cut the silkworm cocoon into pieces, weigh 20g and put it into 0.5% Na by mass at a bath ratio of 1:00 2 CO 3 in aqueous solution. Degumming was carried out in an aqueous solution, and after degumming for 30 minutes, it was washed twice with deionized water; the above steps were repeated, and after three times of washing with deionized water, the silk fibroin sample was flattened and dried in an oven at 50°C to obtain a silk fibroin sample. Silk fibroin fiber; the Na 2 CO 3 The temperature of the aqueous solution is 85-105°C.

[0028] (2) Weigh 10g of silkworm silk fiber in step (1) and add it to LiBr solution with a concentration of 9mol / L and place it in a shaker for 6 hours to accelerate the dissolution to obtain a silk fibroin solution; put the silk fibroin solution on the dialysis membrane Dialyzed with deionized water for 4 days to obt...

Embodiment 2

[0035] (1) Cut the silkworm cocoon into pieces, weigh 20g and put it into 0.5% Na by mass at a bath ratio of 1:00 2 CO 3 in aqueous solution. Degumming was carried out in an aqueous solution, and after degumming for 30 minutes, it was washed twice with deionized water; the above steps were repeated, and after three times of washing with deionized water, the silk fibroin sample was flattened and dried in an oven at 50°C to obtain a silk fibroin sample. Silk fibroin fiber; the Na 2 CO 3 The temperature of the aqueous solution is 85-105°C.

[0036] (2) Weigh 10g of silkworm silk fiber in step (1) and add it to the LiBr solution with a concentration of 9mol / L and place it in a shaker for 5 hours to accelerate the dissolution to obtain a silk fibroin solution; put the silk fibroin solution on the dialysis membrane Dialyzed with deionized water for 4 days to obtain a relatively pure silk fibroin solution, which was naturally air-dried and filtered to obtain a pure silk fibroin s...

Embodiment 3

[0043] (1) Cut the silkworm cocoon into pieces, weigh 20g and put it into 0.5% Na by mass at a bath ratio of 1:00 2 CO 3 in aqueous solution. Degumming was carried out in an aqueous solution, and after degumming for 30 minutes, it was washed twice with deionized water; the above steps were repeated, and after three times of washing with deionized water, the silk fibroin sample was flattened and dried in an oven at 50°C to obtain a silk fibroin sample. Silk fibroin fiber; the Na 2 CO 3 The temperature of the aqueous solution is 85-105°C.

[0044] (2) Weigh 10g of silkworm silk fiber in step (1) and add it to the LiBr solution with a concentration of 9mol / L and place it in a shaker for 5 hours to accelerate the dissolution to obtain a silk fibroin solution; put the silk fibroin solution on the dialysis membrane Dialyzed with deionized water for 4 days to obtain a relatively pure silk fibroin solution, which was naturally air-dried and filtered to obtain a pure silk fibroin s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com