Method for producing geopolymer binding material by red mud and geopolymer binding material

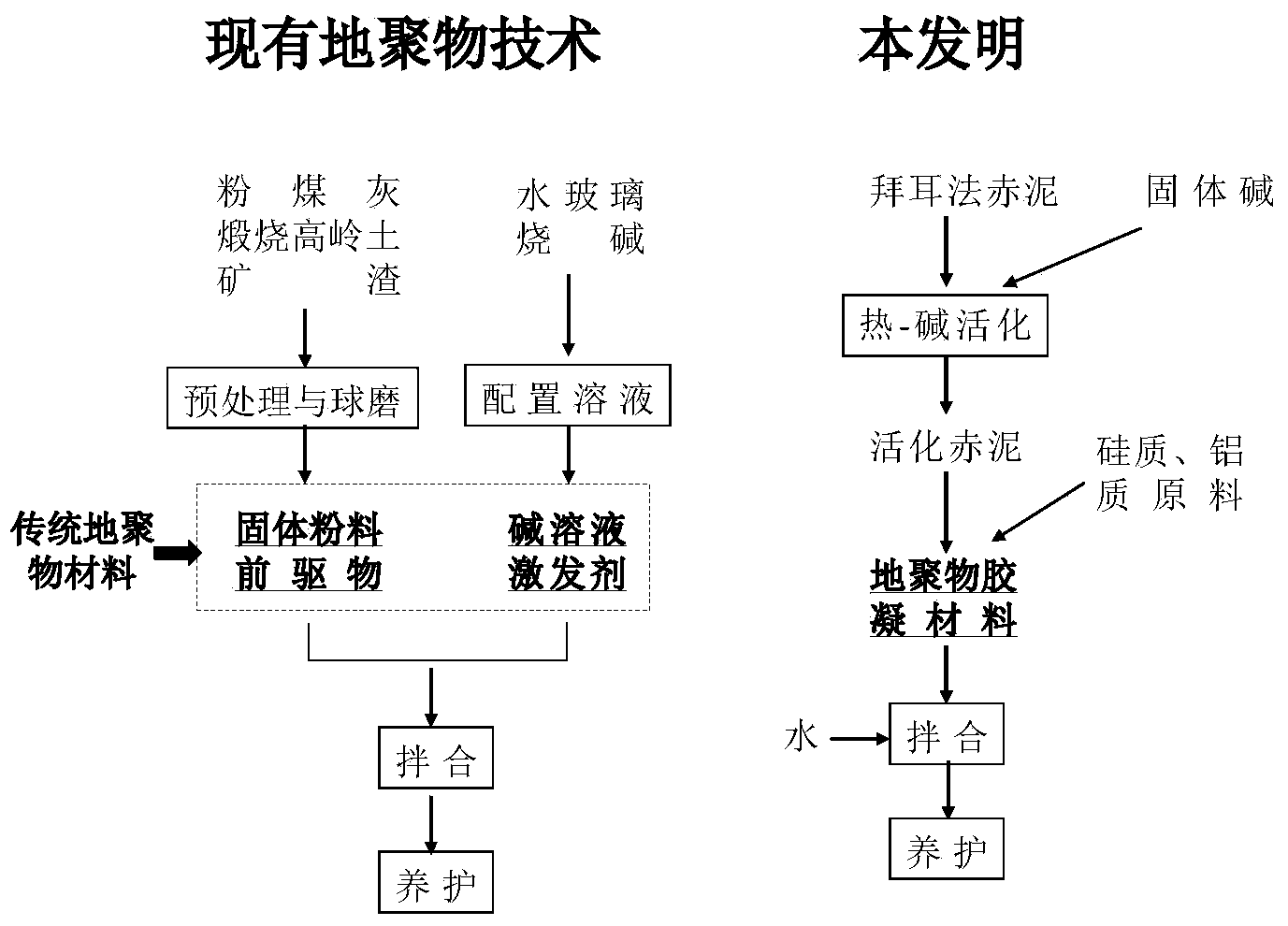

A technology of cementitious materials and production methods, which is applied in the direction of cement production, etc., can solve the problems of on-site configuration of water glass solution or caustic soda aqueous solution, and can only be applied to preformed bricks, tiles, and low addition of Bayer red mud. Achieve the effect of large red mud utilization, convenient application and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method of producing geopolymer cementitious material with red mud, comprising the following steps:

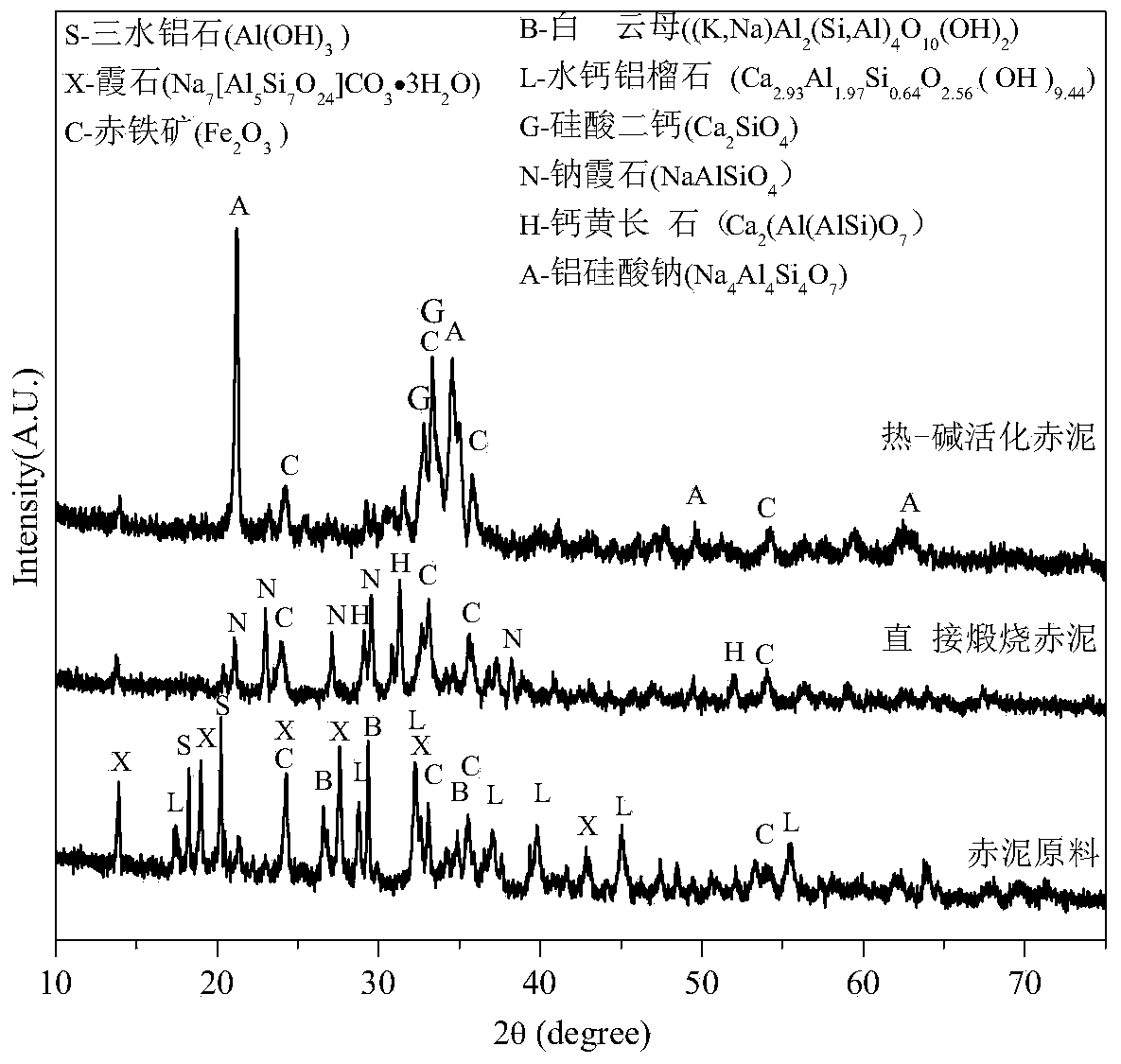

[0042] (1) Mix red mud and sodium hydroxide evenly, and the amount of sodium element in sodium hydroxide added per kilogram of red mud is 3 moles. The red mud is Bayer process red mud, obtained according to the following method: dry the solid or semi-solid Bayer process red mud residue, grind it through a sieve with a pore size of 0.3 mm, and obtain the Bayer process red mud. The Bayer process red mud residue is taken from a certain place in Henan, and its main chemical composition is 20.38% SiO 2 , 24.50%Al 2 o 3 , 9.48%Fe 2 o 3 , 11.46%Na 2 O, 12.86% CaO, loss on ignition at 1200°C is 15.40%.

[0043] (2) Calcining the mixture obtained in step (1) at 900° C. for 1 hour, and cooling to obtain heat-alkali activated red mud. The activated red mud is ground and passed through a sieve with a pore size of 0.3mm.

[0044] (3) The activated red mud obtained in step (...

Embodiment 2

[0047] A method of producing geopolymer cementitious material with red mud, comprising the following steps:

[0048] (1) Mix red mud and potassium hydroxide evenly, and the amount of potassium element in potassium hydroxide per kilogram of red mud is 5 moles. The red mud is Bayer process red mud, obtained according to the following method: dry the solid or semi-solid Bayer process red mud residue, grind it through a sieve with an aperture of 0.5mm, and obtain the Bayer process red mud. The Bayer process red mud residue is taken from a certain place in Henan, and its main chemical composition is 20.38% SiO 2 , 24.50%Al 2 o 3 , 9.48%Fe 2 o 3 , 11.46%Na 2 O, 12.86% CaO, loss on ignition at 1200°C is 15.40%.

[0049] (2) Calcining the mixture obtained in step (1) at 800° C. for 2 hours, and cooling naturally to obtain activated red mud. The activated red mud is ground and passed through a sieve with a pore size of 0.5mm.

[0050] (3) The activated red mud obtained in step ...

Embodiment 3

[0053] A method of producing geopolymer cementitious material with red mud, comprising the following steps:

[0054] (1) Mix red mud and sodium carbonate evenly, and the amount of sodium element in sodium carbonate added per kilogram of red mud is 4 moles. The red mud is Bayer process red mud, obtained according to the following method: drying solid or semi-solid Bayer process red mud residue, grinding through a sieve with an aperture of 0.4 mm, and obtaining the Bayer process red mud. The Bayer process red mud residue is taken from a certain place in Henan, and its main chemical composition is 20.38% SiO 2 , 24.50%Al 2 o 3 , 9.48%Fe 2 o 3 , 11.46%Na 2 O, 12.86% CaO, loss on ignition at 1200°C is 15.40%.

[0055] (2) Calcining the mixture obtained in step (1) at 700° C. for 3 hours, and cooling naturally to obtain activated red mud. The activated red mud is ground and passed through a sieve with a pore size of 0.4mm.

[0056] (3) The activated red mud obtained in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com