A purging device for removing foreign matter on the surface of an electrostatic chuck

An electrostatic chuck and foreign object technology, which is applied in the direction of cleaning methods, circuits, and electrical components using gas flow, can solve problems such as increasing wafer deformation, vacuum tank pressure alarm, and increasing the process time of purging, so as to avoid Negative pressure alarm problem, convenient operation, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

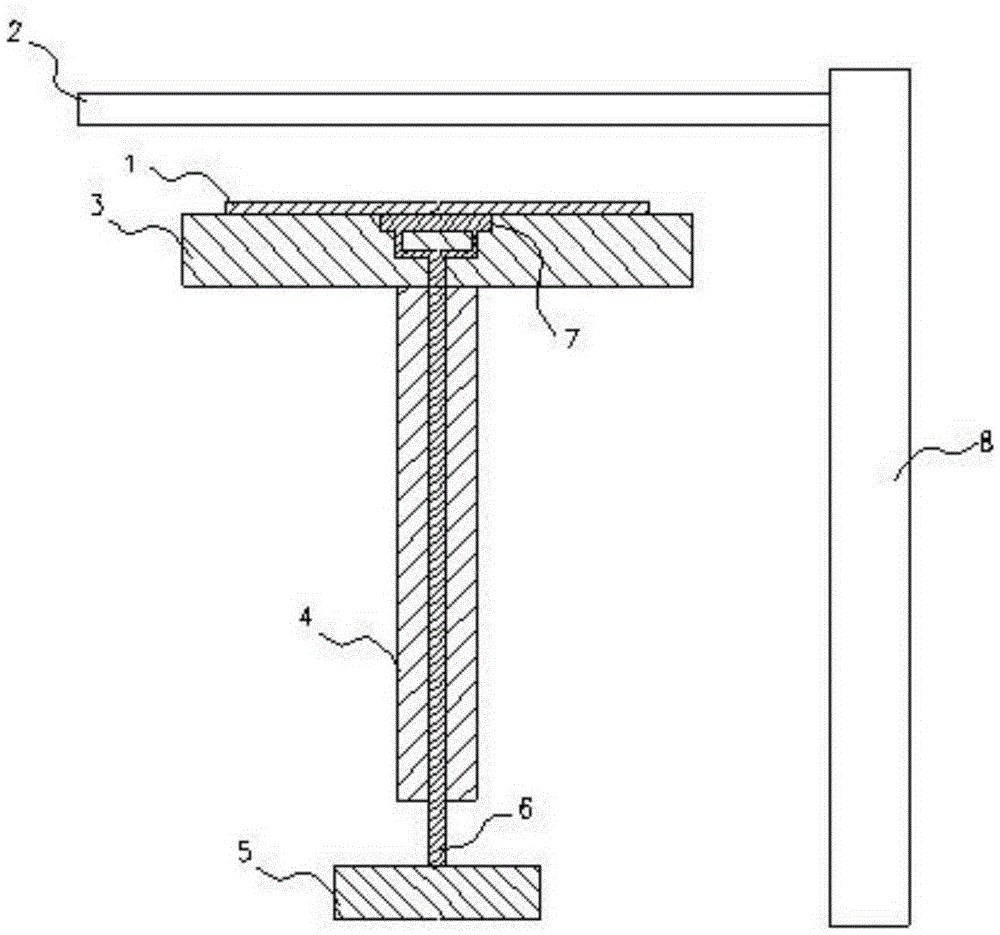

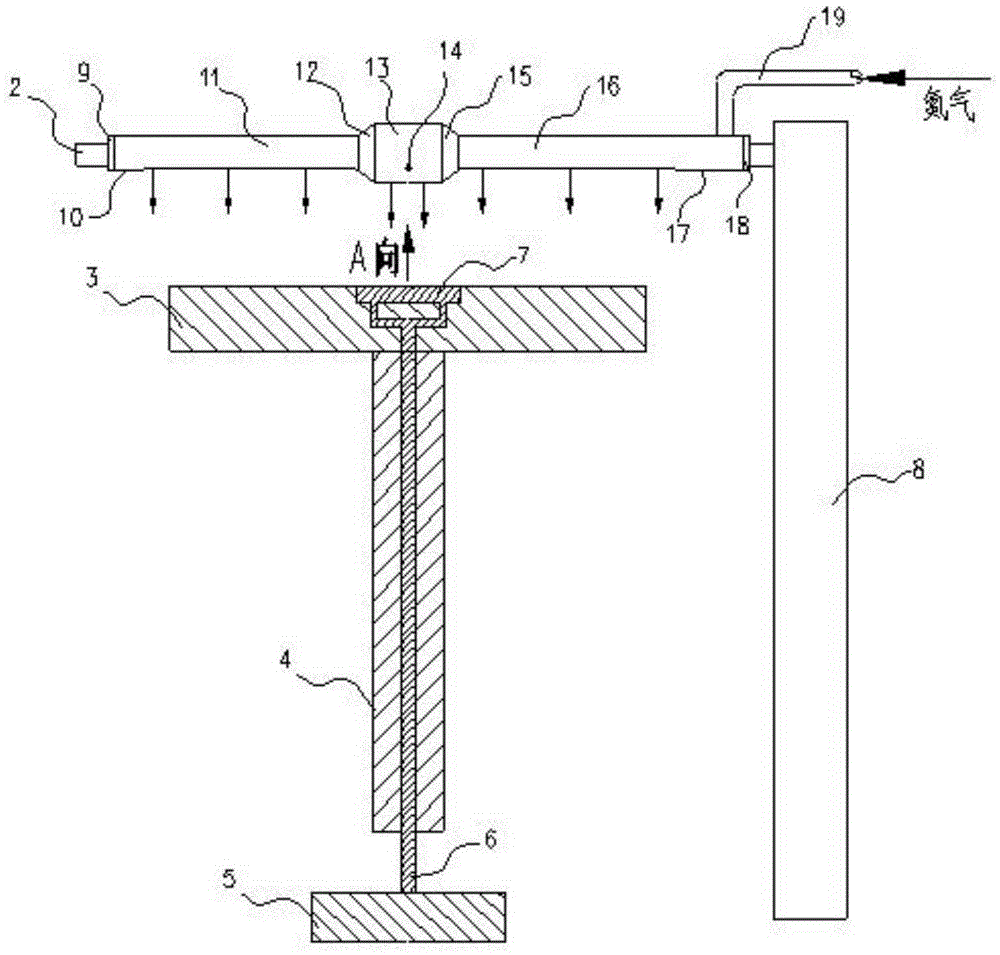

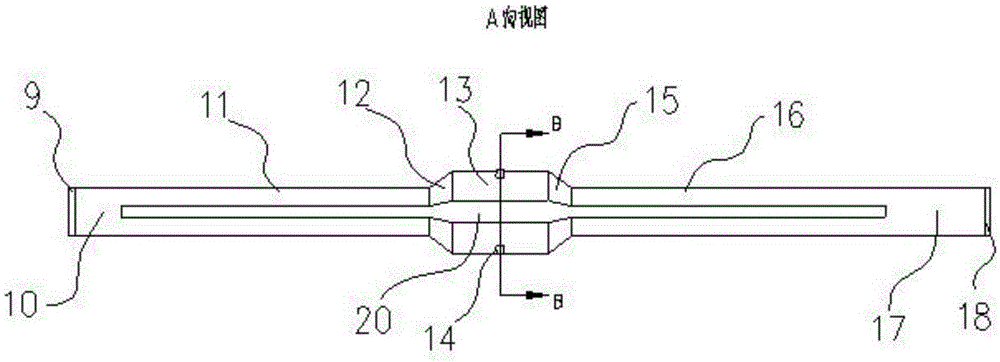

[0039] Such as Figure 2 to Figure 4As shown, a purging device for removing foreign matter on the surface of an electrostatic chuck 3 includes a column 8 arranged vertically to the ground, a cantilever beam 2 arranged horizontally, an electrostatic chuck 3, an electrostatic chuck bracket 4, a negative pressure pump 5, a vacuum Pipeline 6, vacuum tank 7, one end of the cantilever beam 2 is connected to the side of the column 8 near the top; it also includes a middle section nozzle 13, a root nozzle 16, a top nozzle 11, a root blind plate 18 and a top blind plate 9 , the root blind plate 18 and the top blind plate 9 are respectively connected to the outer ends of the root nozzle 16 and the top nozzle 11 in a full welding manner, and the middle section nozzle 13, the root nozzle 16 and the top nozzle 11 are arranged with slotted The opening 20 and the root nozzle 16 are connected with a nitrogen gas inlet pipeline 19 above the side near the column 8, and the nitrogen gas introduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com