Spunbond nonwoven fabrics

A non-woven fabric and spun-bonded technology, applied in the field of spun-bonded non-woven fabrics, can solve the problems of increased complexity, increased cost, and reduced capacity of various resins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0061] The following examples illustrate the invention but are not intended to limit the scope of the invention. The examples of the present invention demonstrate that monocomponent fibers comprising ethylene-based polymer compositions facilitate the spinning of fine denier fibers and soft / drapeable spunbond nonwovens while maintaining Maximum highest tensile strength accepted.

[0062] Invention Example Compositions 1-5

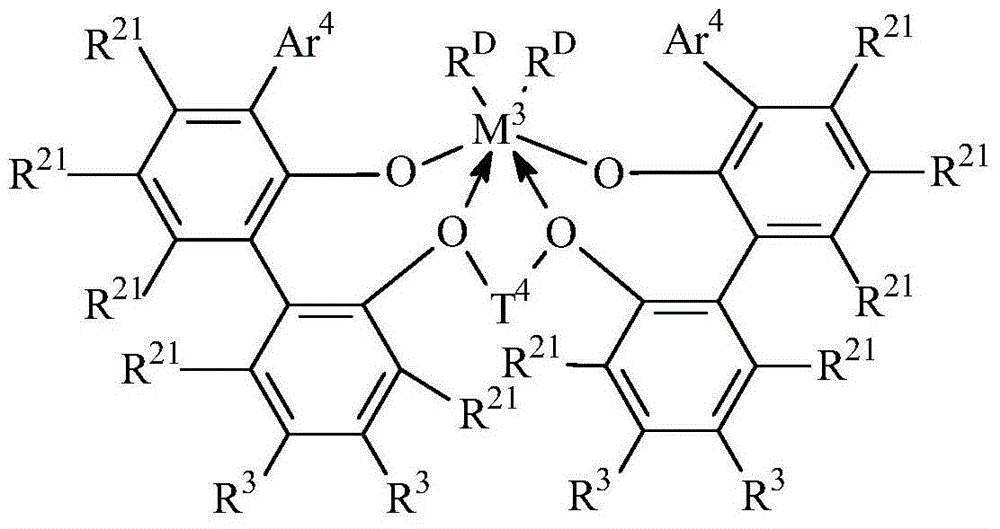

[0063] Inventive Example Compositions 1-2 and 4-5 are ethylene prepared as described above by a solution polymerization process in a two-reactor configuration connected in series in the presence of a catalyst system comprising a metal complex of a polyvalent aryloxyether. - Octene copolymer. The properties of the ethylene-octene copolymer compositions of Inventive Example Compositions 1-2 and 4-5 are reported in Table 1.

[0064] Inventive Example Composition 3 is an ethylene-hexene copolymer prepared as described above by a gas phase polymerization pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com