Method for determining bisphenol A without condensing and remelting for collecting extraction agent

An extraction agent, bisphenol technology, applied in the field of bisphenol A determination, to achieve the effects of environmental friendliness, saving coagulation, and rapid method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 The method for collecting the extractant to measure bisphenol A without condensation and melting again comprises steps:

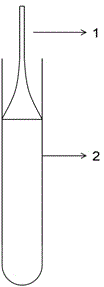

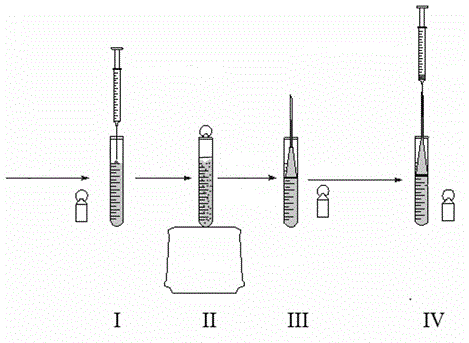

[0023] (1) Vortex-assisted liquid-phase microextraction based on the extractant collection device: use the extractant collection device, use a small amount of isooctyl alcohol as the extractant, use a vortex oscillator to vortex the water sample and the extractant system, and extract The vortex-assisted liquid phase microextraction in which the agent is broken into fine droplets to speed up the extraction speed; the extraction agent collection device is composed of a glass tube 1 and a glass tube 2, the glass tube 2 contains the water sample to be measured, and the inner diameters of both ends are the same, and the glass tube The inner diameter of both ends of 1 is very different, the outer diameter of the thick end is slightly smaller than the inner diameter of the glass tube 2, which just covers the surface of the water sample above the...

Embodiment 2

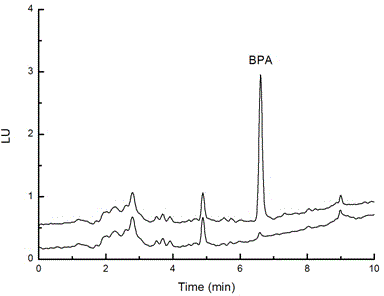

[0025] Example 2 The analysis method of bisphenol A in the raw water of a certain river is (1) separation and enrichment of bisphenol A based on the vortex-assisted liquid phase microextraction of the extractant collection device, (2) based on high performance liquid chromatography-fluorescence Detector for the detection of bisphenol A.

[0026] (1) Separation and enrichment of bisphenol A by vortex-assisted liquid phase microextraction based on extractant collection device: Take 5 mL of water containing bisphenol A and put it in a glass test tube, add 30 μL of isooctyl alcohol extractant, and use vortex Vortex-assisted extraction of water was performed with a shaker for a total of 90 s. During vortex extraction, bisphenol A in water is extracted into isooctyl alcohol. After the extraction was completed, it was left to stand for 2 minutes, and the isooctyl alcohol extractant droplets floated on the surface of the water because the density was smaller than that of water. use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com