Preparation method of wear-resistant alloy cast iron

A wear-resistant alloy and cast iron technology, which is applied in the field of wear-resistant alloy cast iron, can solve the problems of short replacement period, high use cost, easy sand falling, etc., and achieve the effects of impact resistance, less equipment and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

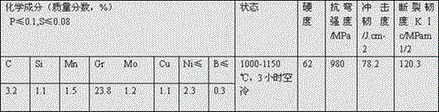

[0013] Implement Column 1:

[0014] (1) Furnace charge preparation and smelting: Use medium frequency induction furnace for smelting, prepare 1 ton charge, use low-carbon steel scraps as base material, add 400 kg of 58% high-carbon ferrochrome and low-carbon ferrochrome to make the molten iron contain 23% chromium When the carbon content reaches 3.2%, add 8-10 kg of 70% ferromanganese when the steel material and the added ferrochrome have just melted into water; while making slag, add 20 kg of 60% ferromolybdenum, and appropriately add ferrotungsten and ferroboron , when the furnace temperature reaches 1550°C, remove slag, and then add 8-10 kg of 70% ferromanganese. Add 12 kg of pure copper and 2-3 kg of nickel plate; rare earth silicon, ferrosilicon, clear water, and take samples to test and adjust the chemical composition. It is required that the furnace charge should not be wet, and the steel charge should not be rusted. During the smelting process, the alkaline furnace c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com