Method for extracting active components of yeast based on high voltage pulse discharge technology

A high-voltage pulse discharge and active component technology, which is applied in the field of extracting active components, can solve problems such as unfavorable industrial production, thermal reduction of protein and nucleic acid biological activity, and cumbersome soil treatment, so as to achieve suitable promotion and application, and improve the extraction rate. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

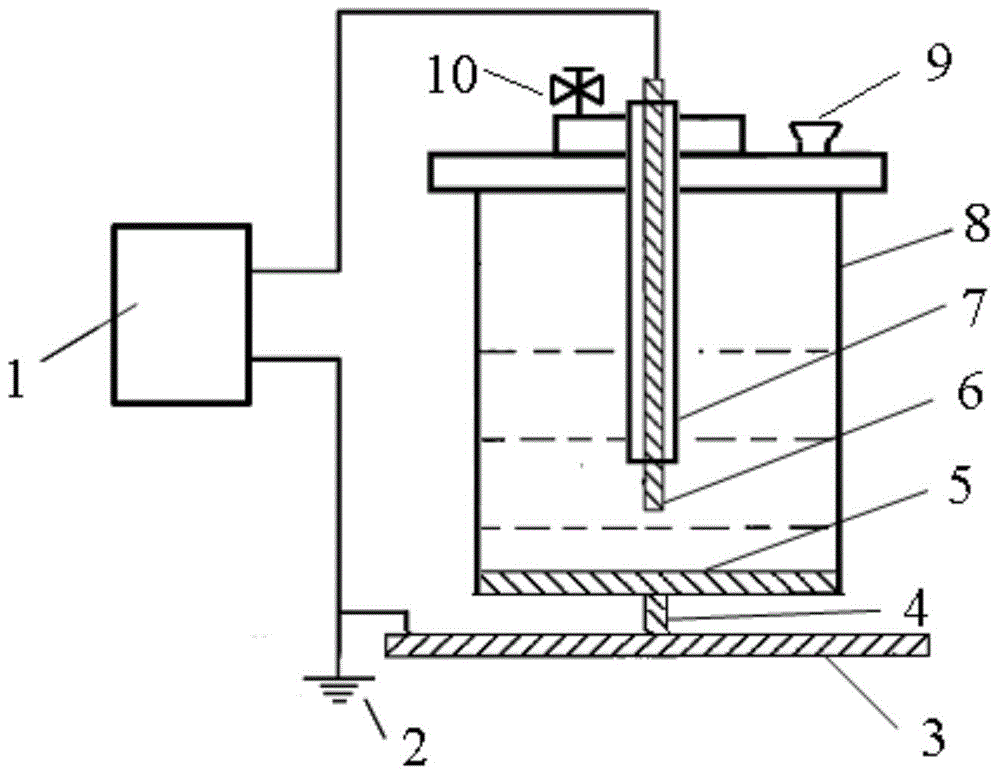

[0026] figure 1 The high-voltage pulse discharge treatment chamber used in this embodiment includes a high-voltage pulse discharge power supply 1, a ground wire 2, a ground electrode 3, a connecting plate 4, a flat plate electrode 5, a multi-pin electrode 6, an insulator 7, a treatment chamber 8, and a sample inlet 9 , Vent 10.

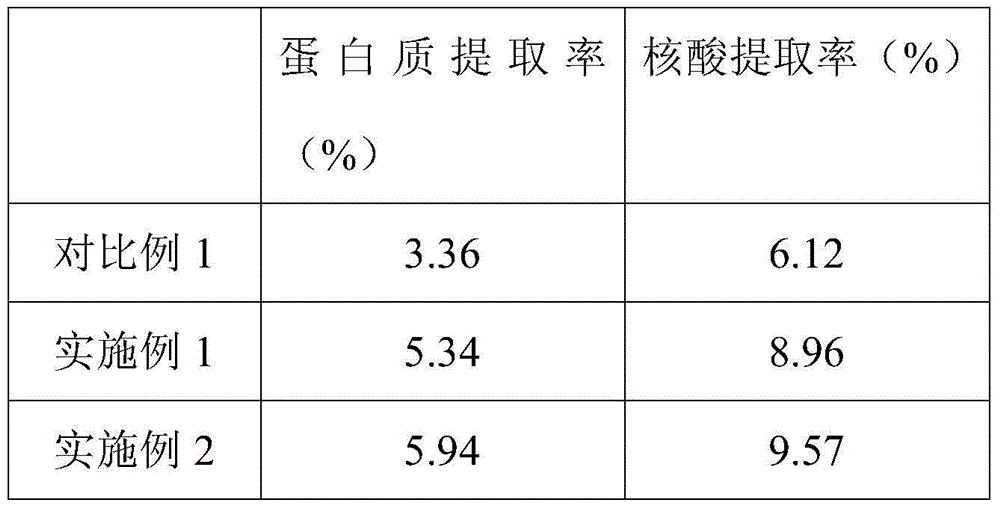

[0027] The yeast active component extraction method based on high-voltage pulse discharge technology of the present embodiment, the steps are as follows: put 10g beer dry yeast (protein content 48-50%, nucleic acid content 6%~9%) in 35 Rehydrate in warm water at ℃ for 15 minutes to make a yeast suspension. Move the prepared beer yeast suspension through the sample inlet into the high-voltage pulse discharge treatment chamber for treatment. Adjust the multi-needle electrodes so that the distance between the multi-needle electrodes and the plate electrodes is kept at 10 cm. The pulse discharge voltage is 10kV, the frequency is 50Hz, the pulse width is ...

Embodiment 2

[0037] The method for extracting yeast active components based on high-voltage pulse discharge technology in this embodiment, the steps are as follows:

[0038] Put 20g of beer dry yeast (48-50% protein content, 6%-9% nucleic acid content) at a ratio of 1:20 in warm water at 38°C for 20 minutes to make a yeast suspension, and prepare the beer yeast suspension Move the samples into the high-voltage pulse discharge treatment chamber through the sample inlet for treatment, and adjust the multi-needle electrodes so that the distance between the multi-needle electrodes and the plate electrodes is kept at 40 cm. The pulse discharge voltage is 40kV, the frequency is 200Hz, the pulse width is 100μs, the pulse number is 1000 times, and the pulse electric treatment time is 20s. The extract rich in active components is obtained, centrifuged at a speed of 4000 r / min for 10 min with a centrifuge, and protein and nucleic acid are obtained in the supernatant. The isoelectric point precipita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com