Preparation method of composite nano ZnO voltage-sensitive ceramic powder

A pressure-sensitive ceramic and powder technology, which is used in the preparation and application of electronic ceramics, can solve the problems of high production cost, different particle sizes, complex processes, etc., and achieves high potential gradient, large nonlinear coefficient and small leakage current. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

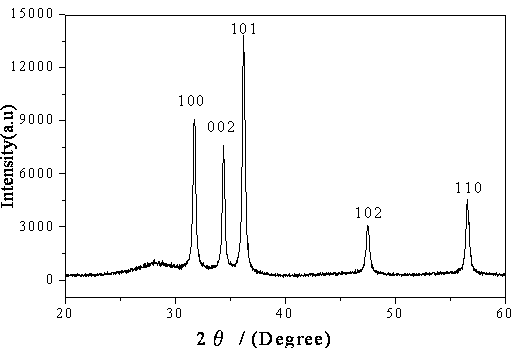

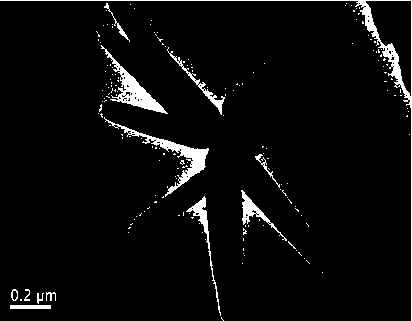

[0029] 1. Preparation of nanocomposite ZnO powder

[0030] (1) Dissolve 11.4349g of zinc nitrate into a 0.1 mol / L solution; dissolve bismuth nitrate, cobalt nitrate, and manganese chloride into aqueous solutions, respectively, and add them to 0.1 mol / L zinc nitrate solution under stirring. The added amount of the substance conforms to the molar ratio of 95:3:1:1, and the pH of the solution is adjusted to 8 with ammonia water, and stirring is continued for 2h.

[0031] (2) The obtained precipitate was filtered with suction, and washed with deionized water and ethanol to remove impurities. The obtained precursor was refluxed in ethanol medium for 2 hours, and the reflux temperature was controlled at 80 °C.

[0032] (3) Finally, the powder obtained by reflux was suction filtered, and washed with deionized water and ethanol to remove impurities. Finally, it was dried in a vacuum drying oven at 70 °C for 4 hours. After taking out, it was ground in an agate mortar to obtain nanocomp...

Embodiment 2

[0037] In this example, when preparing nanocomposite ZnO powder, the weight of each component is the same as in Example 1. The pH value of the solution is adjusted with ammonia water to 8.5, and stirring is continued for 2 hours; Reflux for 3 hours; the above materials are prepared into ZnO varistor ceramics by the same process steps as those in Example 1, the difference is that the sintering temperature of the ceramics is 1150°C.

Embodiment 3

[0039] In this example, when preparing nanocomposite ZnO powder, the weight of each component is the same as in Example 1, the pH value of the solution is adjusted with ammonia water to 8, and stirring is continued for 2 hours; Reflux for 4 hours; the above materials are prepared into ZnO varistor ceramics by the same process steps as those in Example 1, the difference is that the sintering temperature of the ceramics is 1050°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com