Multi-station spindle-swinging-type five-axis numerical control engraving and milling machine

A multi-station, engraving and milling technology, applied in engraving, processing models, decorative arts, etc., to achieve the effect of compact structure and high-quality processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

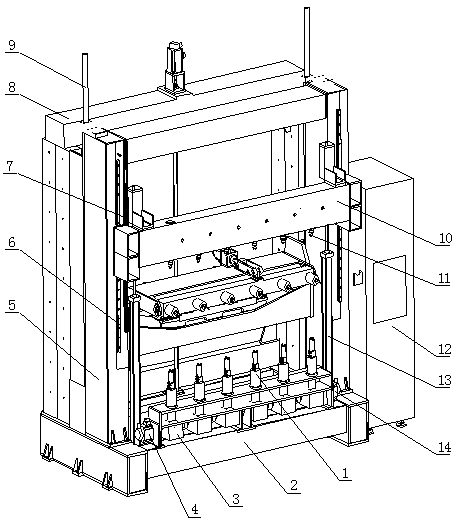

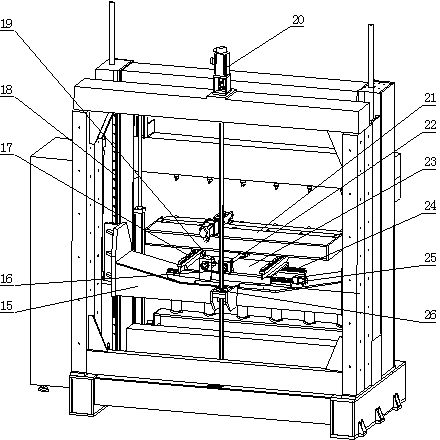

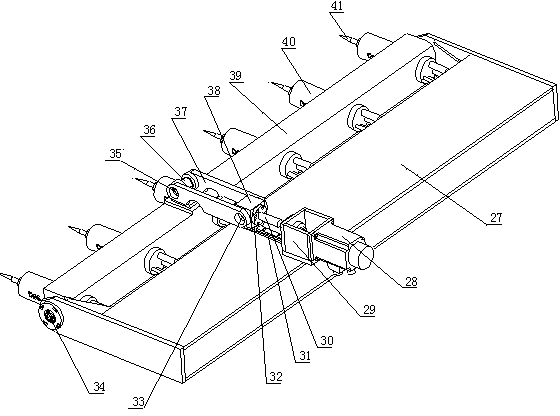

[0021] refer to figure 1 , figure 2 with image 3 , a multi-station five-axis CNC engraving and milling machine tool. Its described processing frame is formed " door " shape structure by bed base 2 , column 5 and fixed beam 8 .

[0022] The C-axis system is installed on the bed base 2: the C-axis system consists of two parts, the left and the right, consisting of the workpiece shaft 1, the reducer 3, the left C-axis servo motor 4 and the right C-axis servo motor 14, and the C-axis on both sides The servo motor drives the left and right sides of the workpiece shaft 1 to rotate respectively. The C-axis is composed of the left and right parts, which can shorten the C-axis transmission chain. The left and right parts turn in opposite directions, which can realize the engraving of symmetrical workpieces.

[0023] Between the bed base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com