Method for recycling iron and titanium in vanadium titano-magnetite

A technology of vanadium titanomagnetite and recovery method, applied in chemical instruments and methods, magnetic separation, solid separation and other directions, can solve the problems of inability to recover titanium concentrate, low recovery efficiency of titanium concentrate, etc., and achieves low cost and operation. Simple, avoid over-grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

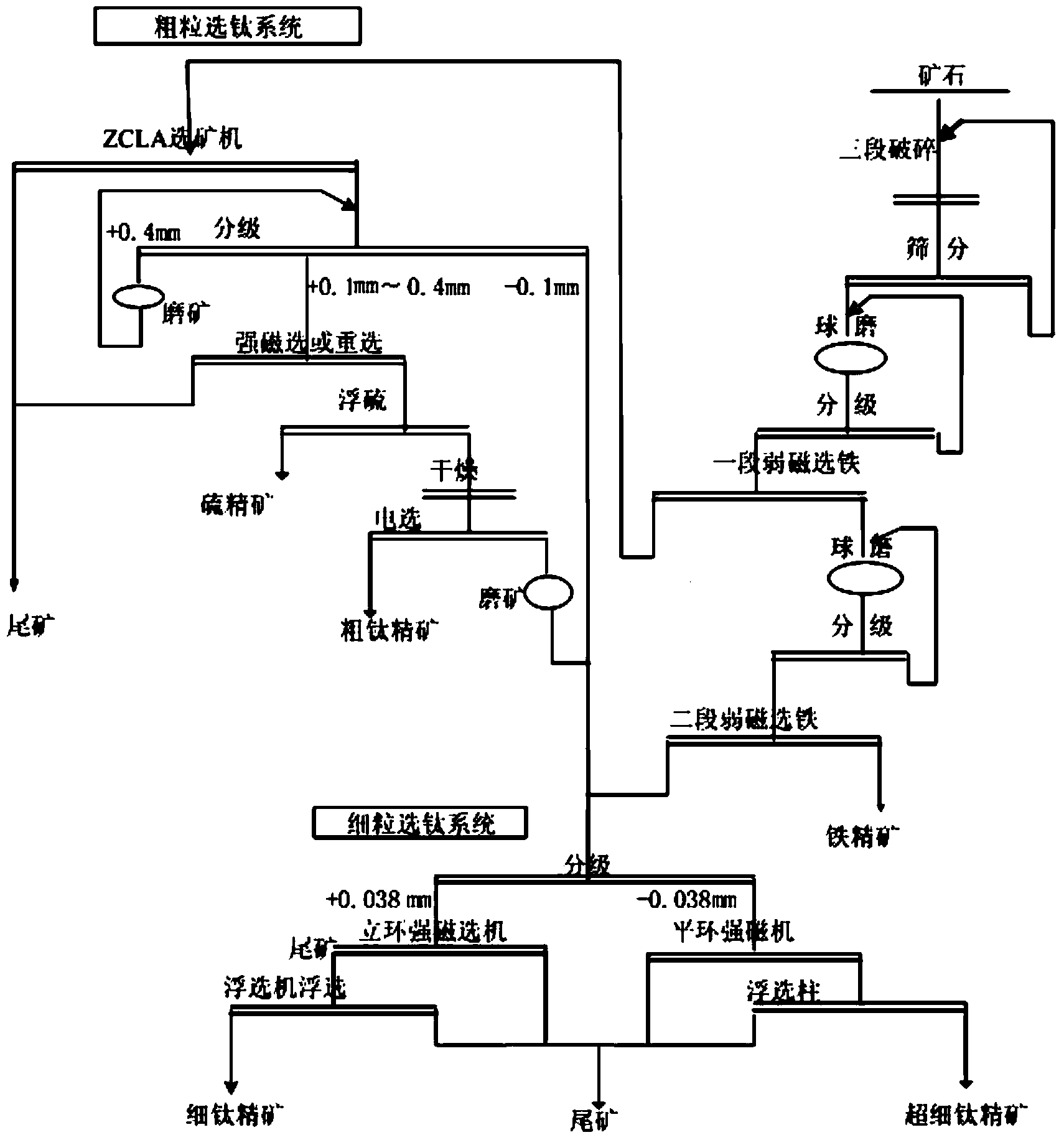

[0065] according to figure 1 The shown flow process recovers iron and titanium in vanadium-titanium magnetite, figure 1 The flow chart of the method for reclaiming iron and titanium in the vanadium-titanium magnetite provided by the embodiment of the present invention, the concrete process is:

[0066] The mass content of 10000 tons of Fe is 28%, TiO 2 The vanadium-titanium magnetite ore with a mass content of 11% is crushed in three stages of closed circuit to obtain mineral powder with a particle size of ≤15mm; the mineral powder with a particle size of ≤15mm is subjected to a stage of ball milling, and the mineral powder obtained from the stage of ball milling is sieved The vibrating screen 200 mesh under the sieve is subjected to a stage of weak magnetic separation with a magnetic field strength of 0.2T to obtain coarse iron ore and tailings of a stage of weak magnetic separation; the coarse iron ore is Two-stage ball milling, the ore powder obtained by the two-stage bal...

Embodiment 2

[0071] according to figure 1 The shown flow process recovers iron and titanium in vanadium-titanium magnetite, figure 1 The flow chart of the method for reclaiming iron and titanium in the vanadium-titanium magnetite provided by the embodiment of the present invention, the concrete process is:

[0072] The mass content of 10000 tons of Fe is 25%, TiO 2 The vanadium-titanium magnetite ore with a mass content of 9.5% is crushed in three stages of closed circuit to obtain ore powder with a particle size of ≤15mm; the ore powder with a particle size of ≤15mm is subjected to one-stage ball milling, and the ore powder obtained by the one-stage ball milling is sieved The vibrating screen 200 mesh under the sieve is subjected to a stage of weak magnetic separation with a magnetic field strength of 0.25T to obtain iron coarse ore and a stage of weak magnetic separation tailings; the iron coarse ore is Two-stage ball milling, the ore powder obtained by the two-stage ball milling is cl...

Embodiment 3

[0077] according to figure 1 The shown flow process recovers iron and titanium in vanadium-titanium magnetite, figure 1 The flow chart of the method for reclaiming iron and titanium in the vanadium-titanium magnetite provided by the embodiment of the present invention, the concrete process is:

[0078] The mass content of 10000 tons of Fe is 20%, TiO 2 The vanadium-titanium magnetite ore with a mass content of 9.0% is crushed in three stages of closed circuit to obtain ore powder with a particle size of ≤15mm; the ore powder with a particle size of ≤15mm is subjected to one-stage ball milling, and the ore powder obtained by the one-stage ball milling is sieved The vibrating screen 200 mesh under the sieve is subjected to a stage of weak magnetic separation with a magnetic field strength of 0.3T to obtain coarse iron ore and tailings of a stage of weak magnetic separation; the coarse iron ore is Two-stage ball milling, the ore powder obtained by the two-stage ball milling is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com