Cement clinker grinding implementation device capable of continuously producing

A cement clinker and grinding technology, applied in grain processing, etc., can solve the problems of over-grinding of materials and the inability of ball mills to adapt to continuous production, etc., and achieve the goals of preventing material feeding from being blocked, optimizing feeding and discharging methods, and reducing energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

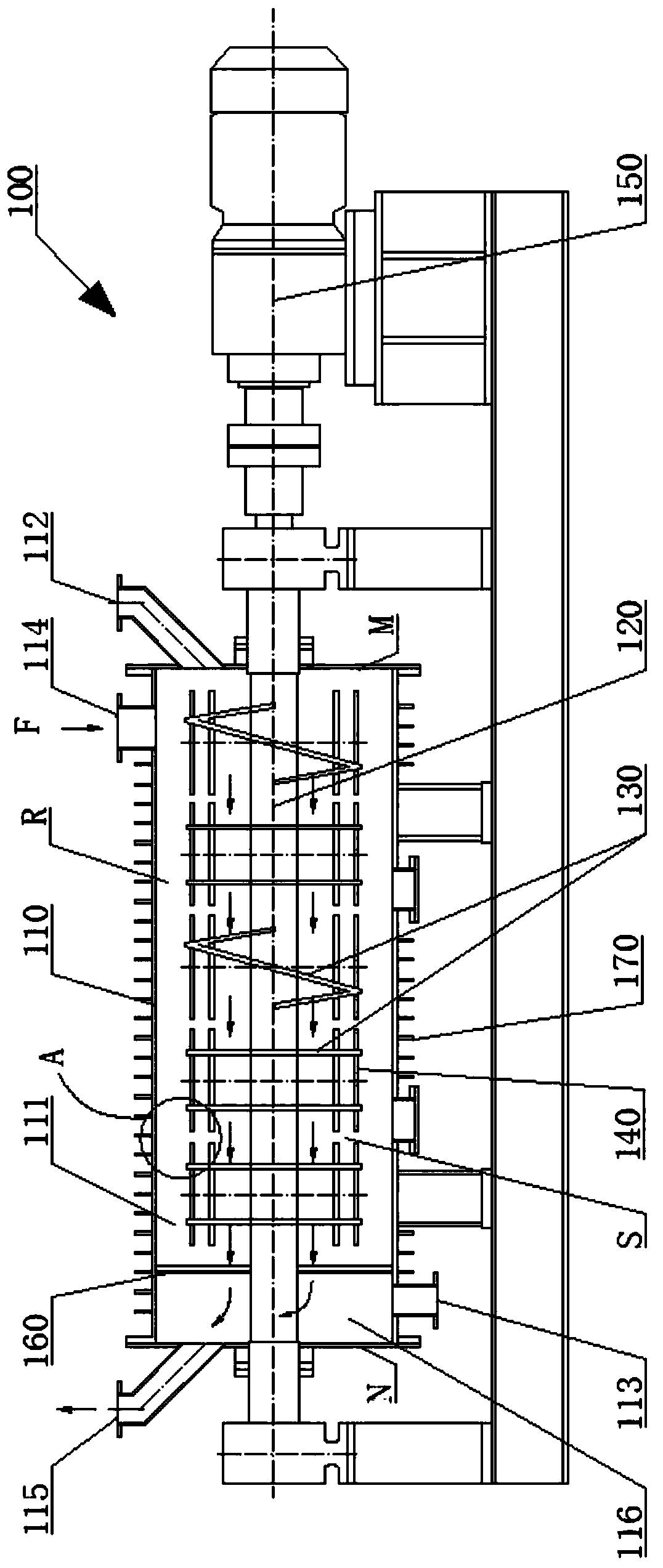

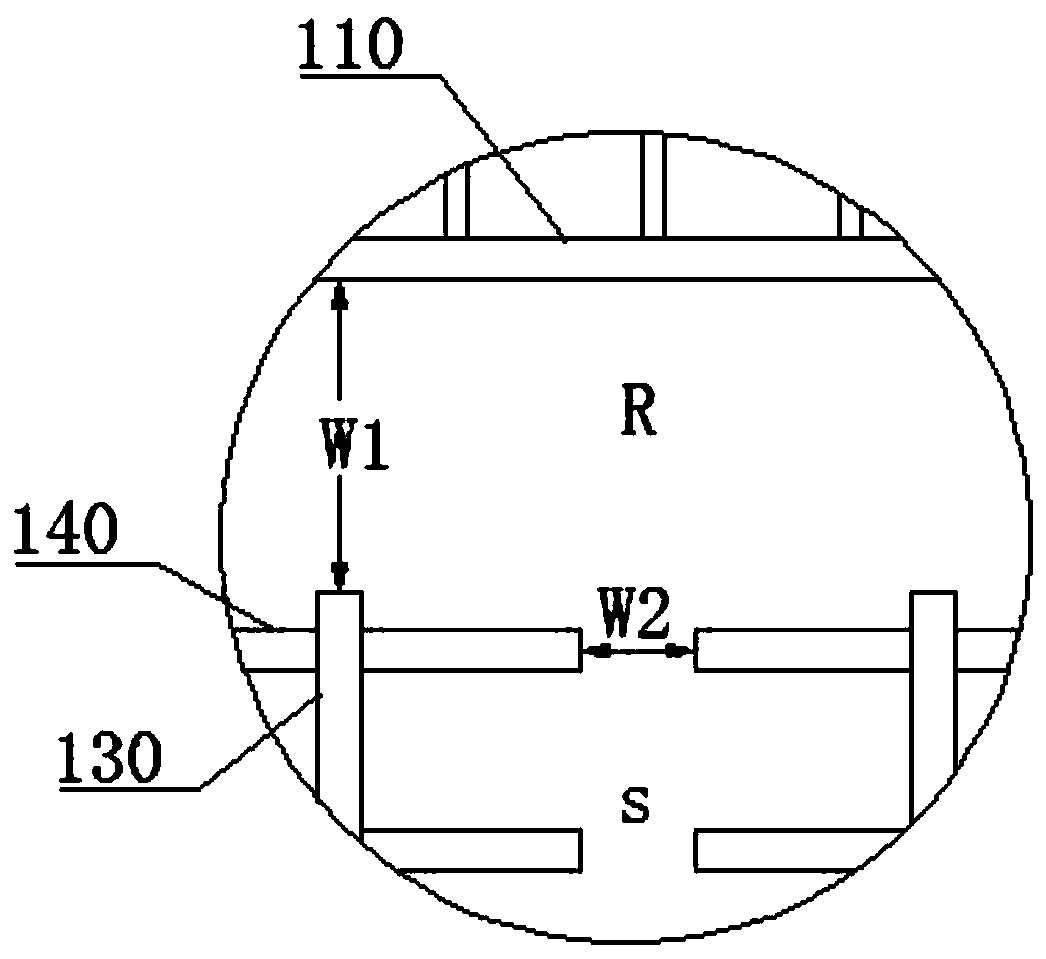

[0027] refer to figure 1 The implementation equipment 100 for continuous production of cement clinker grinding disclosed in this embodiment is illustrated, which includes a housing 110 , a stirring device and a screening device 160 . The housing 110 includes a wall that defines the stirring chamber 111, and a feed port 112 and a discharge port 113 that communicate with the stirring chamber 111. The stirring chamber 111 is filled with roughly spherical grinding media (not shown in the accompanying drawings), to be ground Materials (not shown in the drawings) enter the mixing chamber 111 through the feed port 112 . Stirring device is arranged in stirring chamber 111, and it comprises stirring shaft 120 and stirring unit 130; Through the rotation of the stirring device and the housing 110, at l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com