Powder-liquid stirring and mixing device based on magnetic force driving

A magnetic drive, stirring and mixing technology, used in mixers, mixing methods, mixer accessories, etc., can solve the problems of low mixing efficiency, slow mixing speed, uneven mixing, etc., to improve mixing efficiency, promote mixing, and achieve rotating effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

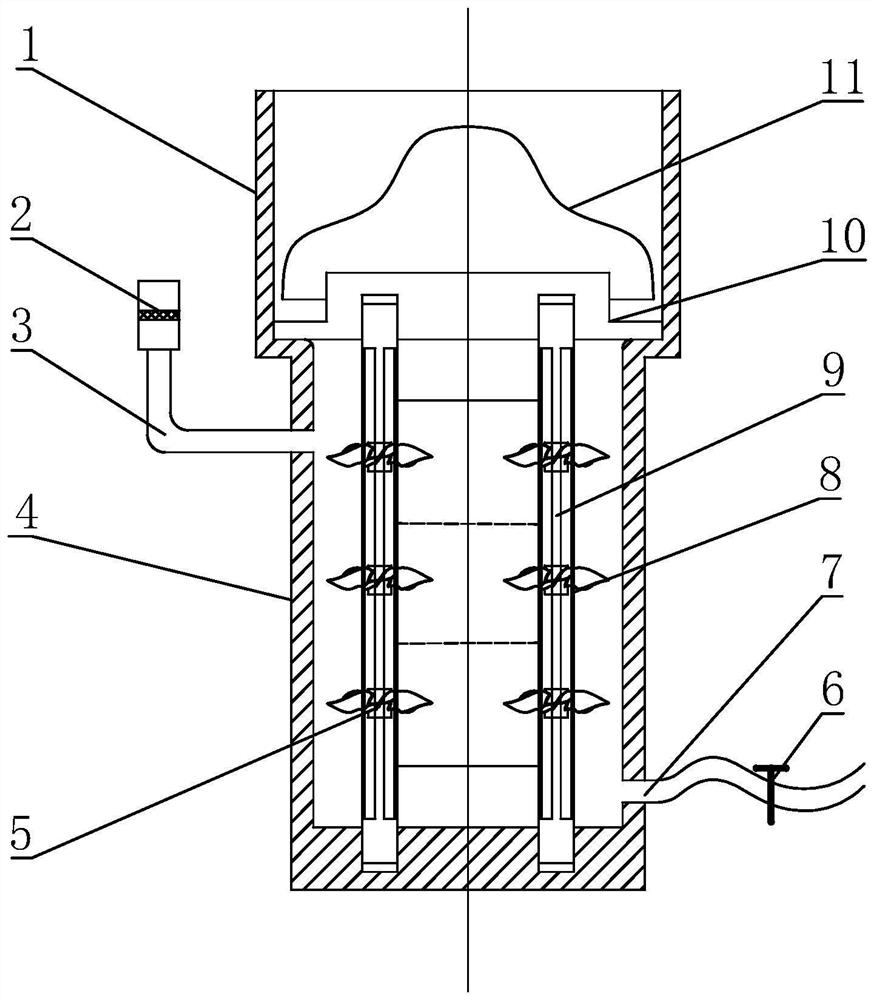

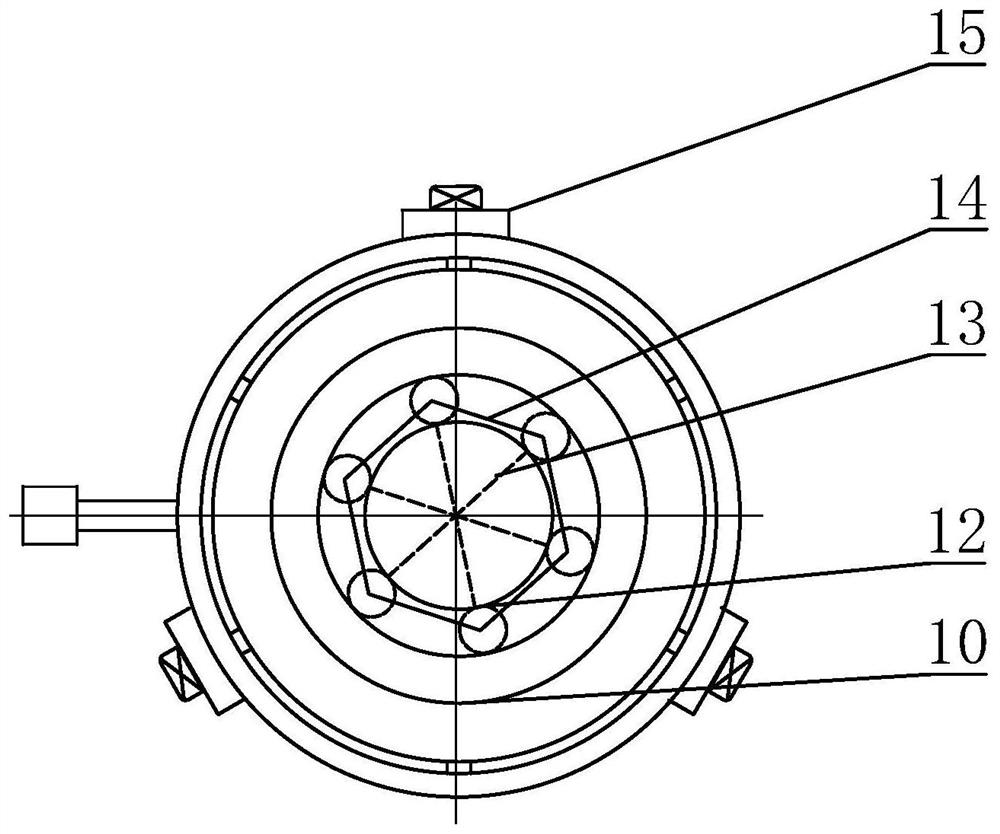

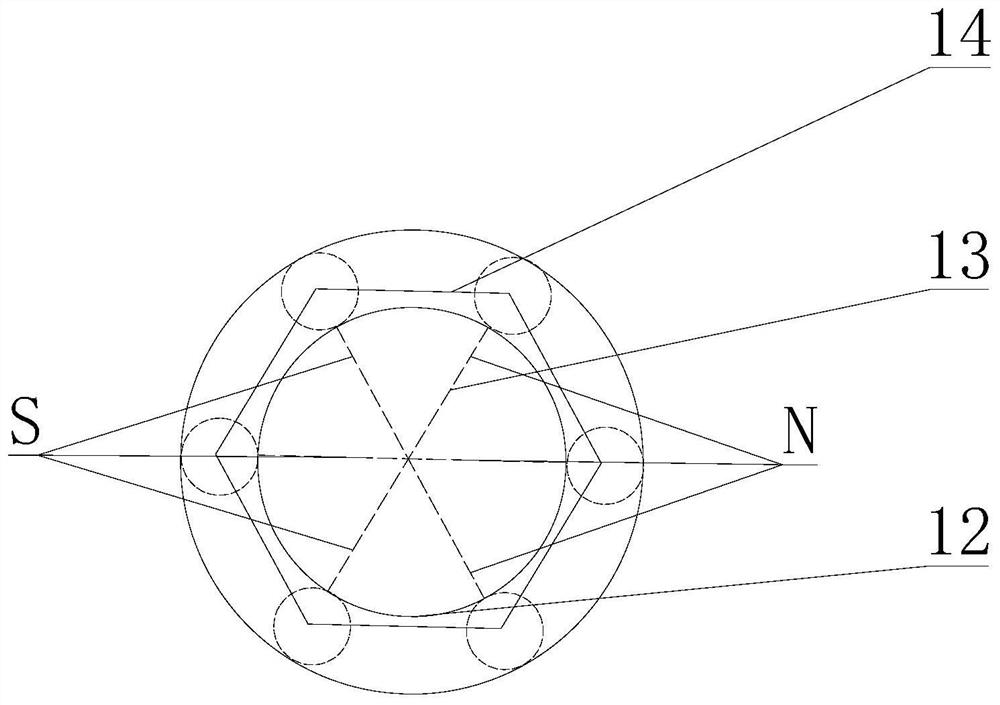

[0036] Such as Figure 1-3 As shown, a stirring and mixing device based on magnetic drive includes a fluid mixing chamber 4, an upper feed flow channel 1 is provided above the fluid mixing chamber 4, and a discharge flow channel 7 is provided at the lower part of the fluid mixing chamber 4. The fluid mixing chamber There is a tangential feed channel 3 on the side wall of the body 4, and a plurality of tangential feed channels 3 can be provided as required, and a magnetically driven turbulence assembly is provided inside the fluid mixing chamber 4.

[0037] The fluid mixing chamber 4 includes a rubber layer and a metal layer, the inner layer is the metal layer, the rubber layer is the outer layer, and the rubber layer covers the outside of the metal layer. The cross section of the fluid mixing chamber 4 is circular, which is convenient for connecting with the external flow channel. There is also a filter 2 at the feed inlet of the tangential feed channel 3 . There is also an ...

Embodiment 2

[0048] The difference between this embodiment and Embodiment 1 is that the fluid mixing chamber 4 is placed in a vertical magnetic field, and the magnetic field changes with a certain period, such as a sinusoidal period. The blade 5 is a magnetic blade 5, and the magnetic blade 5 is strung on the spoiler bar 8 and can slide up and down along the spoiler bar 8. The spoiler bar 8 has a vertical strip groove or a strip flange, There is a through hole in the middle part of the blade 5; when there is a vertical strip groove on the spoiler bar 8, there is a protrusion in the through hole, and the protrusion is stuck in the adjustment groove; when the spoiler bar 8 has a vertical strip When the flange is shaped, the shape of the through hole is the same as the cross section of the spoiler bar 8. The blade 5 slides up and down along the chute on the string rod of the blade 5 under the impact force of the fluid, buoyancy, its own gravity and the magnetic force of the external magnetic ...

Embodiment 3

[0050] In order to explore the mixing effect of the device of the present invention, the COMSOL Multiphysics 5.4 software was used to simulate the entire model. The rotational speed of the magnetic rod and the spoiler set is set at 200RPM, and the magnetic field strength used is 0.145T.

[0051] The concentration value of the diagonal line of the outlet section is selected as a data set, and the mixing intensity is characterized by mixing uniformity and mixing time. The mixing uniformity can better describe the mixing effect of the fluid in the mixing chamber, which can be calculated by formula (1).

[0052]

[0053] In the formula: S c ——mixing uniformity; N——total number of sampling points; c i - normalized concentration on node i; —The expected value of the normalized concentration of the sampling node, which is taken as 0.5.

[0054] Mixing time can describe the speed of mixing, which can be calculated by formula (2).

[0055]

[0056] In the formula: T - mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com