Air stirring pipe for electroplating production equipment

A technology of air stirring and production equipment, which is applied in the direction of electrolysis process, electrolysis components, mixers, etc., can solve the problems of uneven stirring, weak stirring, non-complementary, etc., and achieve enhanced stirring effect, increased bubbles, and enlarged stirring area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

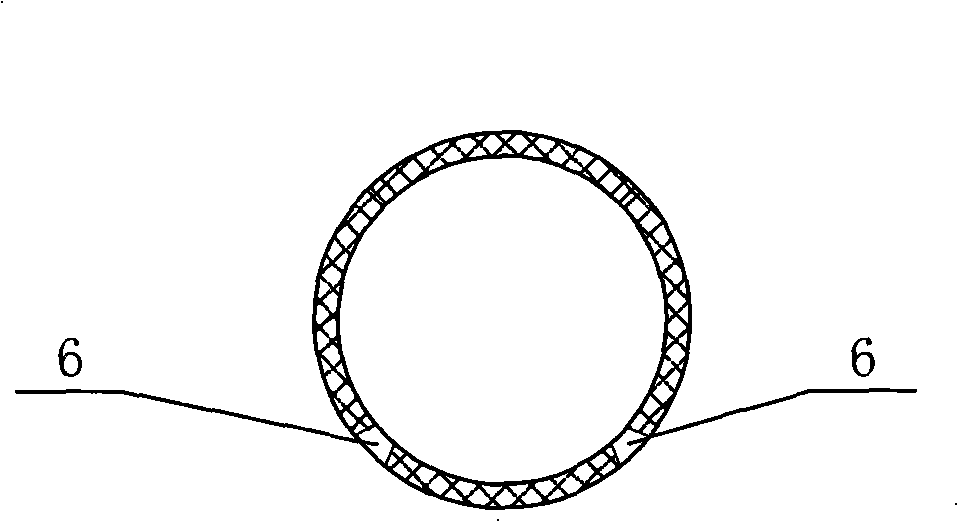

[0012] See Figure 2, Figure 3, Figure 5 , the stirring tube body 2 of the present invention, the stirring tube body 2 is assembled and connected into a "day" shape by the pipe 5 and the elbow 4, the horizontal tube in the middle is connected to the main intake pipe 3, and the air outlet 6 is distributed at the bottom of the stirring tube 2 (see Figure 3), distributed along the airflow direction and the number is getting denser, see Figure 5 . The air outlet hole 6 is a tapered hole with a small inside and a big outside; see Figure 4 , the air outlet holes 6 are staggered; the staggered angle of the adjacent air outlet holes 6 is 120°, 90° or 60° ( Figure 5 90° in the center).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com