Crusher suitable for plastic product processing

A technology of pulverizers and products, applied in the field of mechanical equipment, can solve problems such as pollution and danger, and achieve the effects of optimizing feeding methods, safe feeding, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

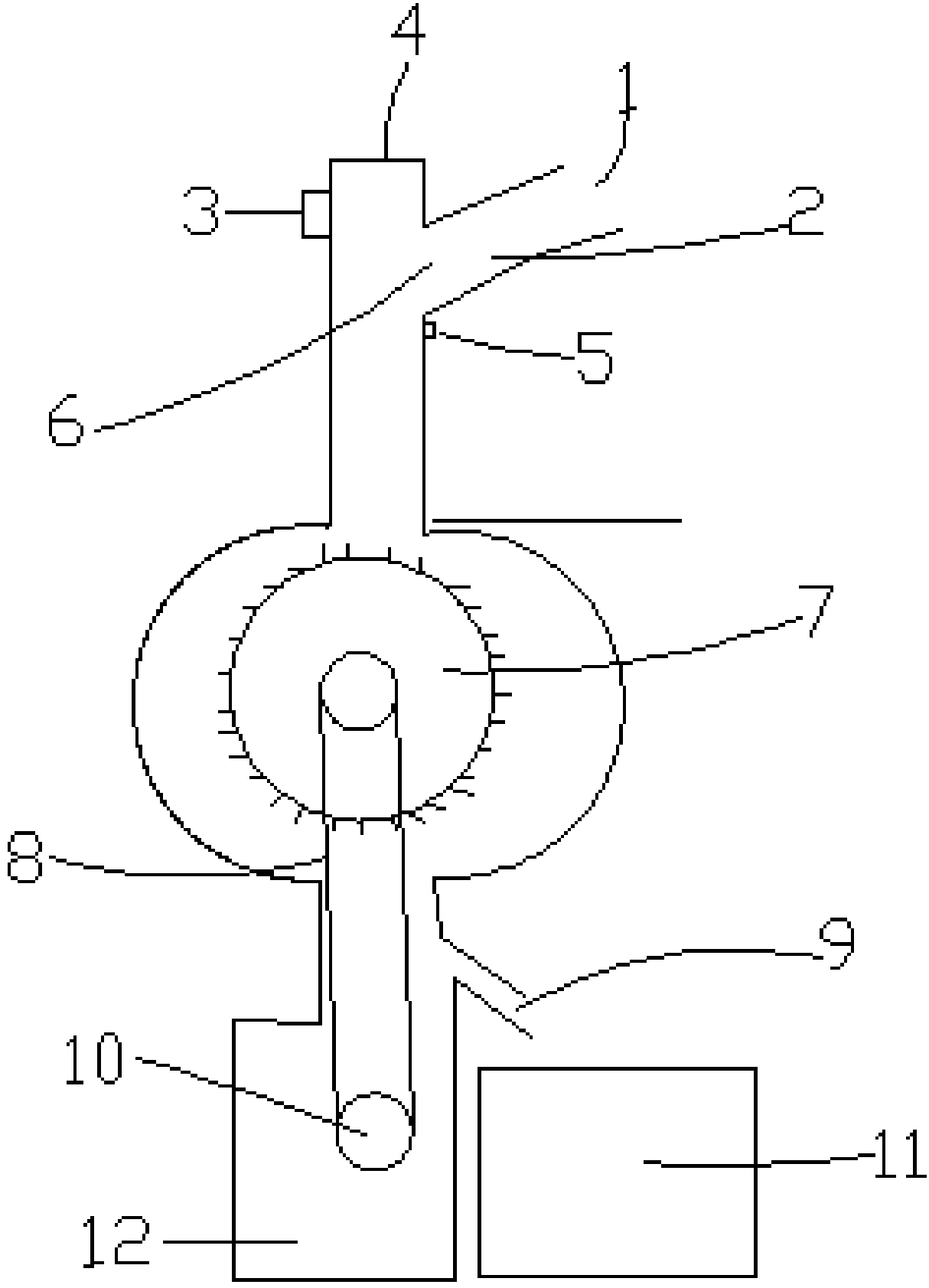

[0012] In order to enable the review committee to have a further understanding of the purpose, features and functions of the present invention, the preferred embodiments are hereby given in detail in conjunction with the drawings as follows:

[0013] Refer to attached figure 1 As shown, it is a structural schematic diagram of a preferred embodiment of the present invention, a pulverizer suitable for processing plastic products, the operation panel 3 is connected to the control electric board through electric wires, and the control electric board is connected to the motor 10 through electric wires, which can Control the switch of the machine; there is a one-way valve 6 at the connection between the feed pipe 2 and the feed pipe 4, and the plastic enters the feed pipe 4 from the feed port through the feed pipe 2 and the one-way valve 6, and the one-way valve 6 is Inward one-way valve, so that the plastic can only go in and out, the shell of the feed pipe 4 close to the feed pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com