Cuprous oxide-titanium dioxide composite structure and preparation method thereof

A technology of cuprous oxide and titanium dioxide, applied in the field of catalysis, to achieve the effect of low raw material price, good monodispersity and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The synthesis of embodiment 1 cuprous oxide hollow sphere

[0057] Under the condition of water bath at 60°C, take 300ml, 0.1mol / L cetyltrimethylammonium bromide, 0.450g copper sulfate pentahydrate respectively, add them to a 500ml three-necked flask in turn, stir in a nitrogen atmosphere for 30min, and pour into the three-necked flask. Add 10ml, 0.45mol / L of newly configured ascorbic acid solution dropwise into the bottle, and you can find that the solution turns from light blue to colorless. After stirring for 30min, add 30ml, 0.6mol / L dropwise into the three-necked bottle. L of sodium hydroxide solution. After adding sodium hydroxide solution, it can be found that bright yellow precipitate cuprous oxide is formed. After separation, it was washed several times with deionized water and ethanol successively to obtain fresh bright yellow cuprous oxide. Scanning electron microscope and transmission electron microscope photos are attached figure 1 And attached figure ...

Embodiment 2

[0058] Example 2 Synthesis of cuprous oxide-titanium dioxide composite structure hollow spheres

[0059] The above bright yellow precipitate (containing about 0.1g of cuprous oxide) was dispersed in 100ml of ethanol, sonicated for 30min, and 10ml of 0.018mol / L tetrabutyl titanate ethanol solution was added dropwise, stirred for 30min, and sonicated for 30min. Add 10 ml of an ethanol solution with a volume ratio of 0.024 water to the suspension under vigorous stirring, stir for 30 minutes, and ultrasonically treat for 30 minutes, so that amorphous titanium dioxide is deposited on the surface of cuprous oxide. After washing several times with ethanol, the obtained catalyst was dried in a vacuum oven at 50 °C for 5 hours.

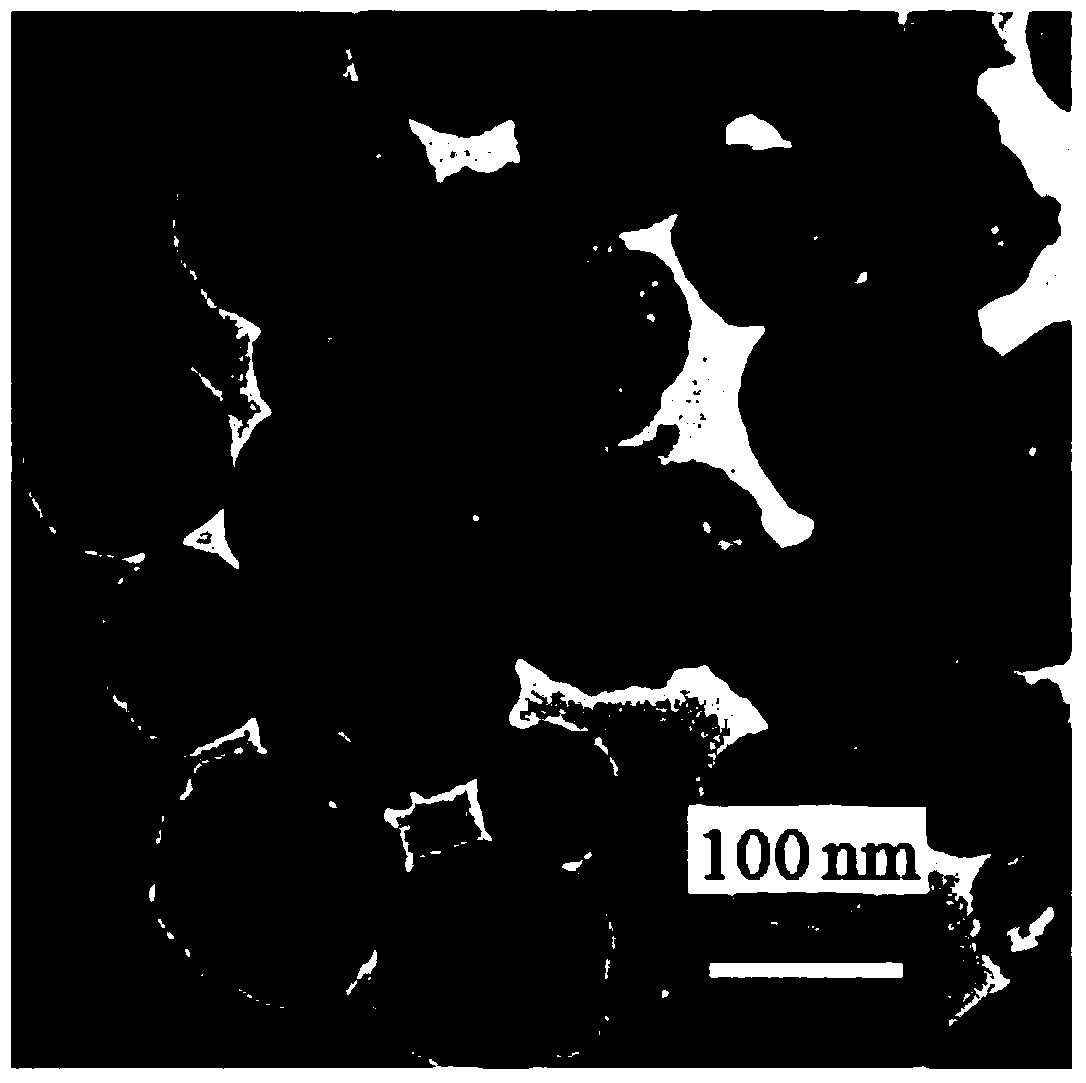

[0060] image 3 A scanning electron microscope picture of cuprous oxide titanium dioxide core-shell hollow spheres prepared in this example; Figure 4 A transmission electron microscope picture of cuprous oxide titanium dioxide core-shell hollow spheres prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com