Sealing material

A technology of sealing materials and polymers, applied in structural parts, battery pack parts, lithium batteries, etc., can solve problems such as easy creep and unsuitable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0097] 26.6 parts of decarbonated and demineralized water were charged into a jacketed autoclave equipped with a stirrer and capable of holding 174 parts of water. The space inside the autoclave was fully replaced with pure nitrogen and then evacuated, and 30.4 parts of perfluorocyclobutane (hereinafter referred to as "C-318"), 0.6 parts of methanol as a chain transfer agent, and 0.5 parts of PPVE were charged. Next, the inside of the autoclave was kept at 35° C. while stirring, and TFE was injected so that the internal pressure was 0.58 MPaG. 0.010 parts of di-n-propyl peroxydicarbonate (hereinafter referred to as "NPP") was added as a polymerization initiator to initiate polymerization. As the polymerization progressed, the pressure in the autoclave decreased, so TFE was injected to maintain the internal pressure at 0.58 MPaG. In addition, PPVE was appropriately added in order to make the polymerization composition uniform.

[0098] After 7.1 hours from the start of the po...

Synthetic example 2~11

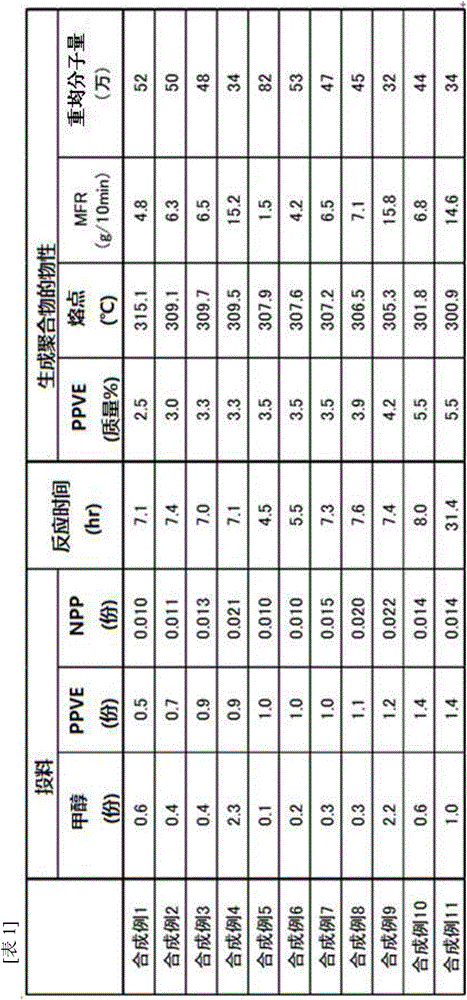

[0106] Polymerized product pellets were produced in the same manner as in Synthesis Example 1, except that the amount of reactants charged and the reaction time were changed as shown in Table 1.

[0107] For the obtained pellets, the copolymer composition (ratio of PPVE), melting point, MFR and weight average molecular weight were measured. The results are listed in Table 1.

[0108]

Embodiment 1

[0110] The pellets of the polymerized product obtained in Synthesis Example 1 were preheated at 350° C. for 1 hour, pressurized at 1 MPaG for 1 minute to form a sheet with a thickness of 20 mm, and cooled naturally to room temperature to obtain a sample sheet.

[0111] The above samples were cut into This was used as a test piece.

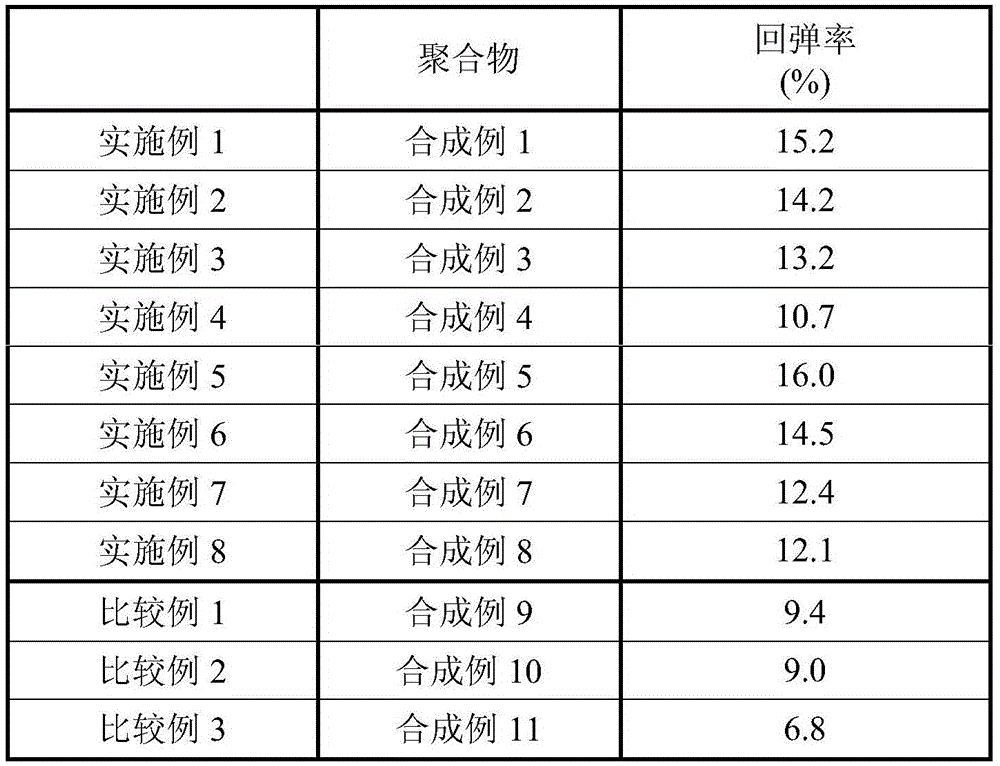

[0112] The rebound rate of the above-mentioned test piece was measured according to the above-mentioned method. The results are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com