Ce-doped water-soluble CdTe quantum dot synthetic method

A synthesis method and technology of quantum dots, applied in the nano field, can solve the problems of unsafe preparation process and complicated operation, and achieve the effects of easy control, simple operation steps and mild synthesis conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

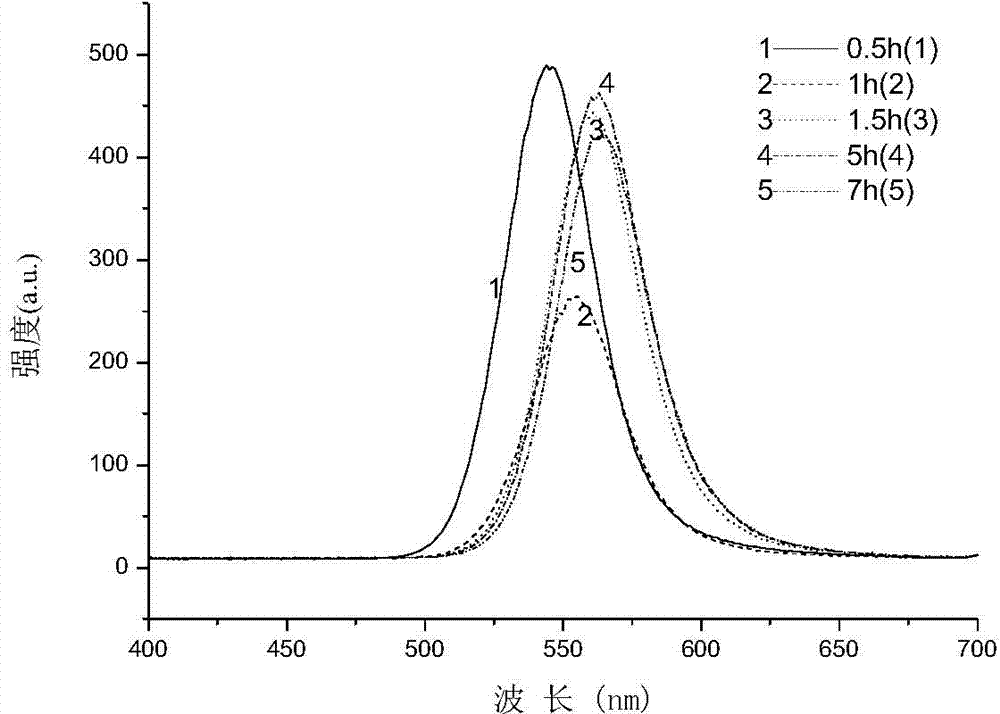

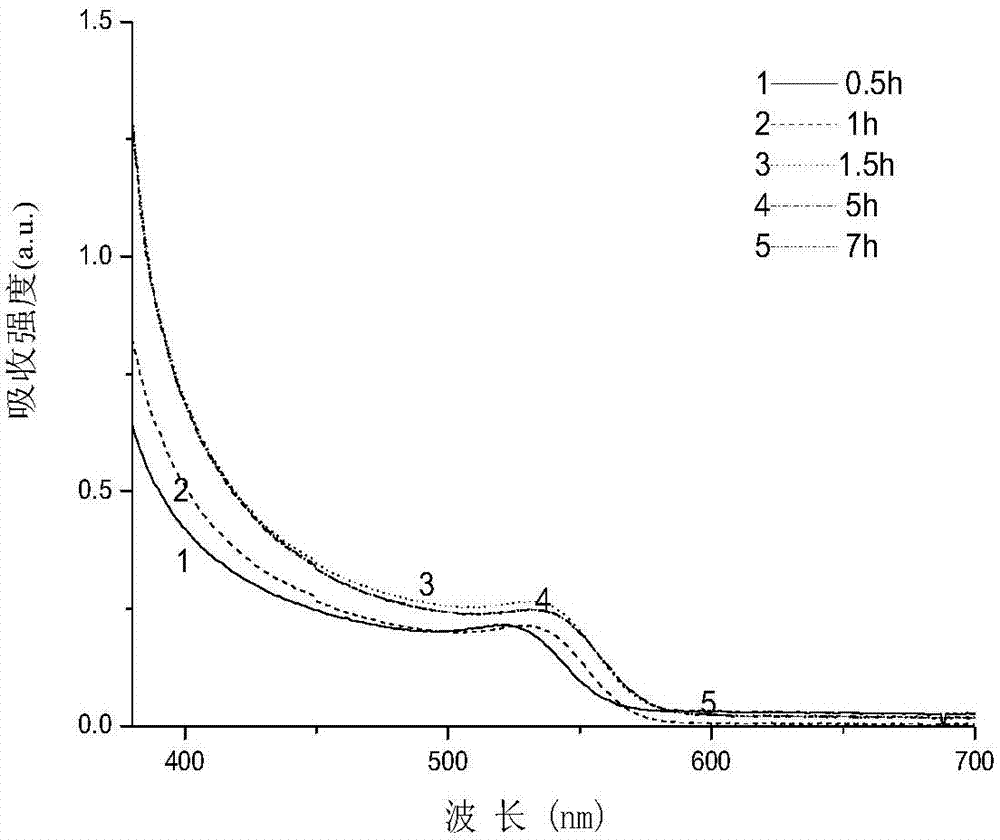

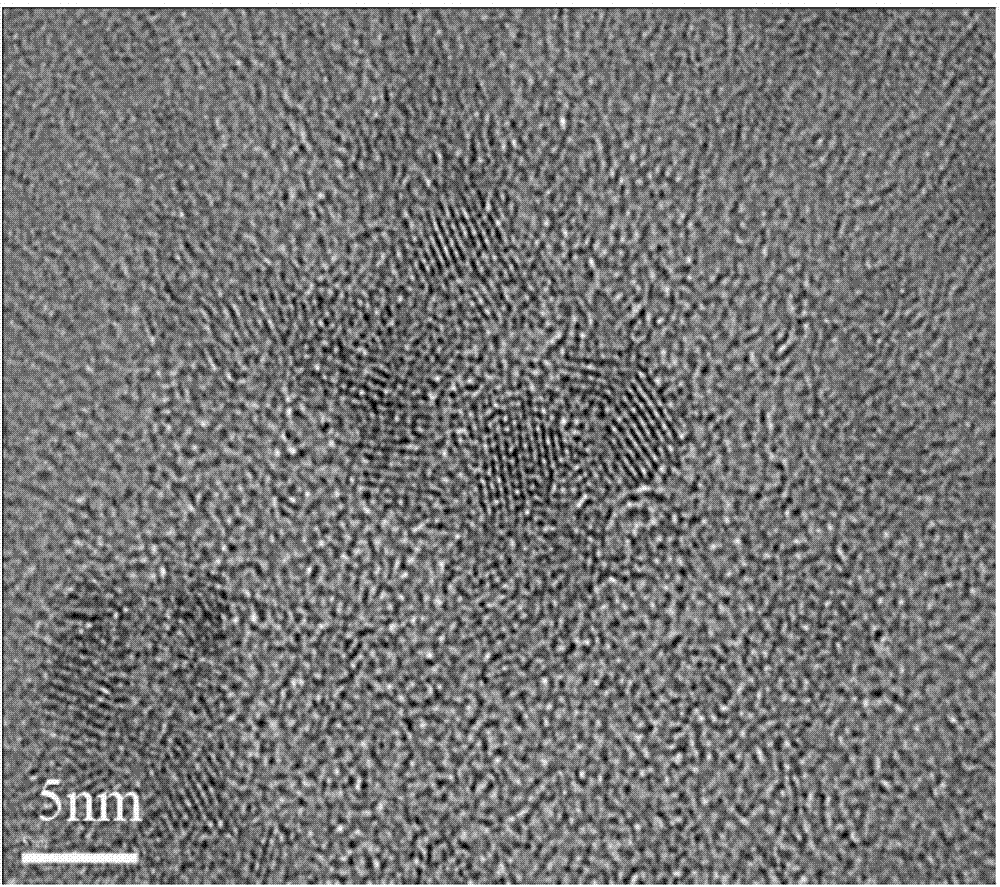

[0028] (1) Measure 98ml of 0.02mol / L cadmium chloride and 2ml of 0.02mol / L cerium ammonium nitrate solution, and put them into three-necked flasks respectively. One port of the three-necked flask is connected to a pipeline for inert gas, and a magnetic stirrer is placed at the middle port The stirring bar of the device, the other port is connected to the gas outflow pipeline, stirred with a magnetic stirrer for 10min, and then added 0.2579g of stabilizer thioglycolic acid (TGA), where (Cd 2+ +Ce 3+ ): The molar ratio of TGA is 1:1.4, and the precursor solution of metal ions is obtained after mixing evenly;

[0029] (2) Nitrogen is passed into the metal ion precursor solution obtained in step (1) to remove oxygen in the bottle, add 0.0096g sodium borohydride, adjust the pH value of the solution to 8.0 with sodium hydroxide, add 0.0313g tellurium dioxide, wherein two The molar ratio of tellurium oxide to sodium borohydride is 1:1.3, TeO 2 with Cd 2+ The molar ratio is 1:10; ...

Embodiment 2

[0033] (1) Measure 97ml of 0.02mol / L cadmium nitrate and 3ml of 0.02mol / L cerium nitrate solution, and put them into three-necked flasks respectively. One of the three-necked flasks is connected to a pipeline for inert gas, and a magnetic stirrer is placed at the middle of the bottle. Stirring bar, the other port is connected to the gas outflow pipeline, stirred with a magnetic stirrer for 8min, and then added 0.5159g of stabilizer thioglycolic acid (TGA), wherein (Cd 2+ +Ce 3+ ): The molar ratio of TGA is 1:2.8, and the precursor solution of metal ions is obtained after mixing evenly;

[0034] (2) Nitrogen is passed into the metal ion precursor solution gained in step (1) to remove oxygen in the bottle, add 0.0220g sodium borohydride, adjust the pH value of the solution to 8.0 with sodium hydroxide, add 0.0309g tellurium dioxide, wherein two The molar ratio of tellurium oxide to sodium borohydride is 1:3, TeO 2 with Cd 2+ The molar ratio is 1:10;

[0035](3) Fully magneti...

Embodiment 3

[0038] (1) Measure 96ml of 0.02mol / L cadmium perchlorate and 4ml of 0.02mol / L cerium ammonium nitrate solution, and put them into three-necked flasks respectively. One port of the three-necked flask is connected to a pipeline for inert gas, and a magnetic force is placed in the middle port. The stirring bar of the stirrer, the other port is connected to the gas outflow pipeline, stir with a magnetic stirrer for 12min, then add 0.7370g stabilizer thioglycolic acid (TGA), where (Cd 2+ +Ce 3+ ): The molar ratio of TGA is 1:4, and the precursor solution of metal ions is obtained after mixing evenly;

[0039] (2) Pass helium into the metal ion precursor solution obtained in step (1) to remove oxygen in the bottle, add 0.0436g sodium borohydride, adjust the pH value of the solution to 9.0 with sodium hydroxide, add 0.0306g tellurium dioxide, wherein The molar ratio of tellurium dioxide to sodium borohydride is 1:6, TeO 2 with Cd 2+ The molar ratio is 1:10;

[0040] (3) Fully sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com