Biodegradable polyester/cellulose nanocomposite and preparation method thereof

A technology of nanocomposite materials and biodegradable polyester, which is applied in the field of biodegradable polyester/cellulose nanocomposite materials and their preparation, polycaprolactone/cellulose nanocomposite materials and their preparation, and can solve the problems that cannot be achieved, etc. problem, achieve the effect of improving dispersion and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

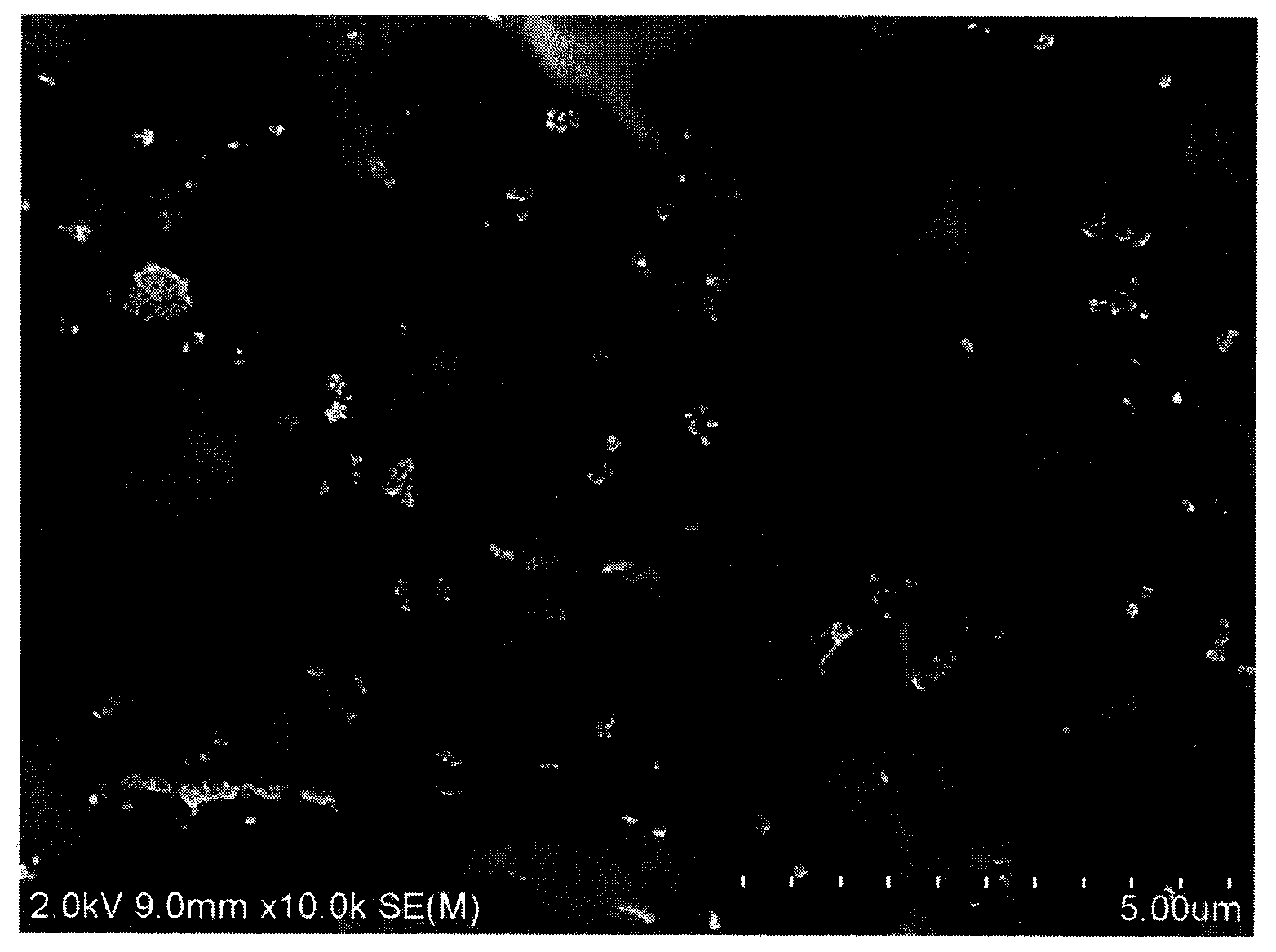

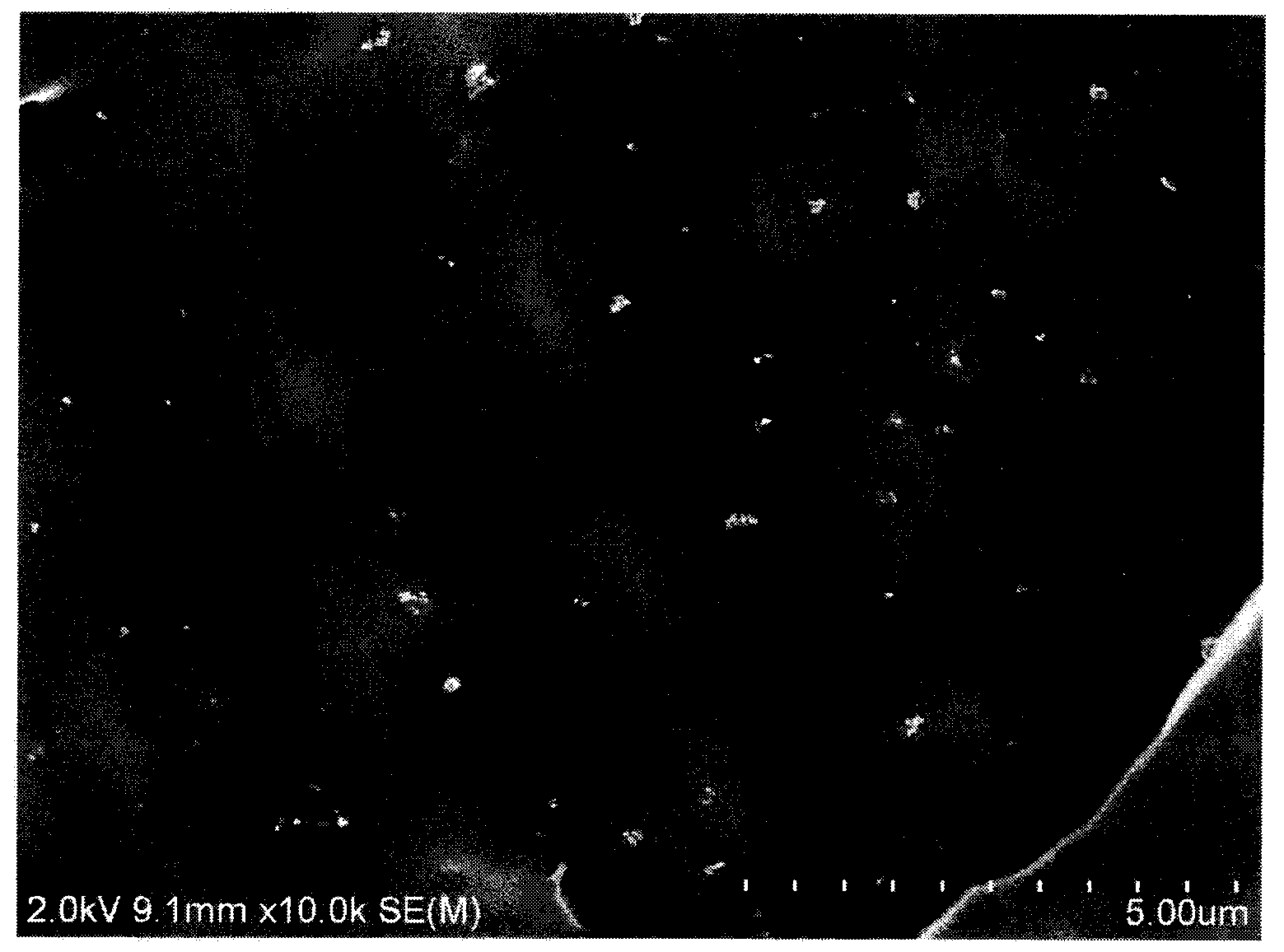

Image

Examples

preparation example Construction

[0019] Preparation of cellulose: Weigh a certain amount of cotton pulp, cut off the coarse powder, dissolve in water, and make starch milk of a certain concentration, then add 5% to 10% hydrochloric acid solution to acidify and heat up to 80°C to 90°C, mechanically Stir for 2h to 4h, sonicate for 0.5h to 1h, wash with deionized water twice, and filter under reduced pressure to obtain microcrystalline cellulose powder. On this basis, the microcrystalline cellulose is prepared by hydrolyzing the microcrystalline cellulose with 60%-70% sulfuric acid aqueous solution. Weigh a certain amount of microcrystalline cellulose and add it to 250mL of 60% to 70% sulfuric acid aqueous solution, stir at 50°C to 60°C for 2h to 5h, centrifuge the crude product suspension, wash until neutral, and filter under reduced pressure Dry to constant weight in a vacuum oven at 40°C.

[0020] Preparation of compatibilizer:

[0021] 1. Weigh 11.4g of dehydrated and dried caprolactone (moisture content2 ...

Embodiment 1

[0025] After mixing 2000g polycaprolactone (PCL), 4g cellulose and 0.4g compatibilizer COS-PCL, melt blending was carried out to obtain biodegradable polyester / cellulose nanocomposites. Made a standard sample, the properties of the composite material obtained through testing are shown in Table 1.

Embodiment 2

[0029] After mixing 2000g polycaprolactone (PCL), 10g cellulose and 1g compatibilizer COS-PCL, melt blending was carried out to obtain biodegradable polyester / cellulose nanocomposites. Made a standard sample, the properties of the composite material obtained through testing are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com