High-temperature-resistant modified asphalt pavement repairing material and preparation method thereof

A modified asphalt and pavement repair technology, which is applied to building insulation materials, building components, buildings, etc., can solve the problems of difficult application in high-temperature tropical regions, poor high-temperature resistance, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

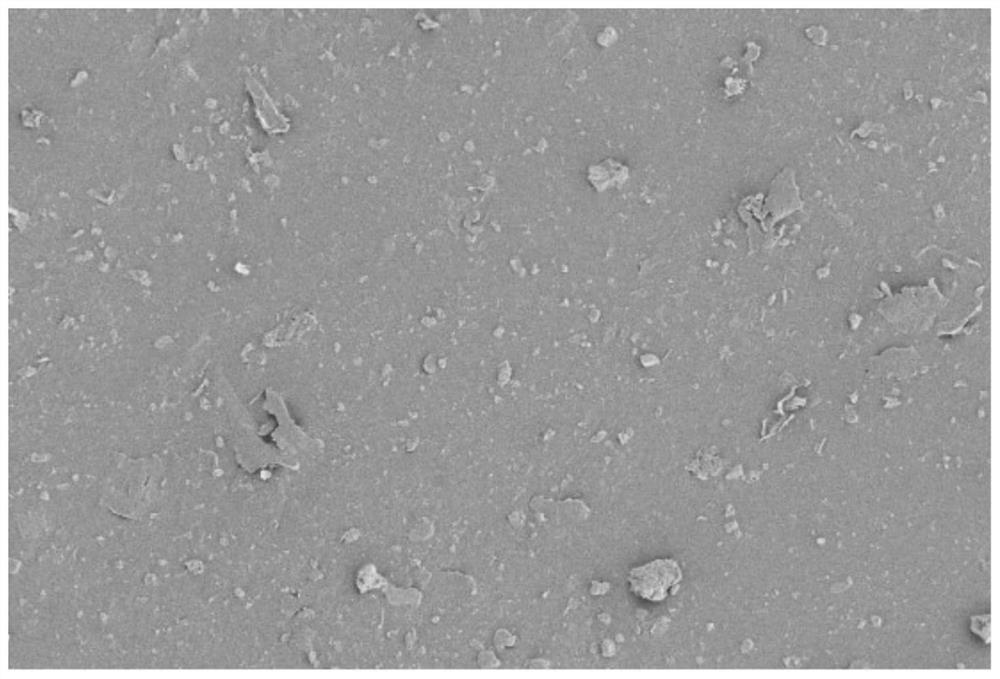

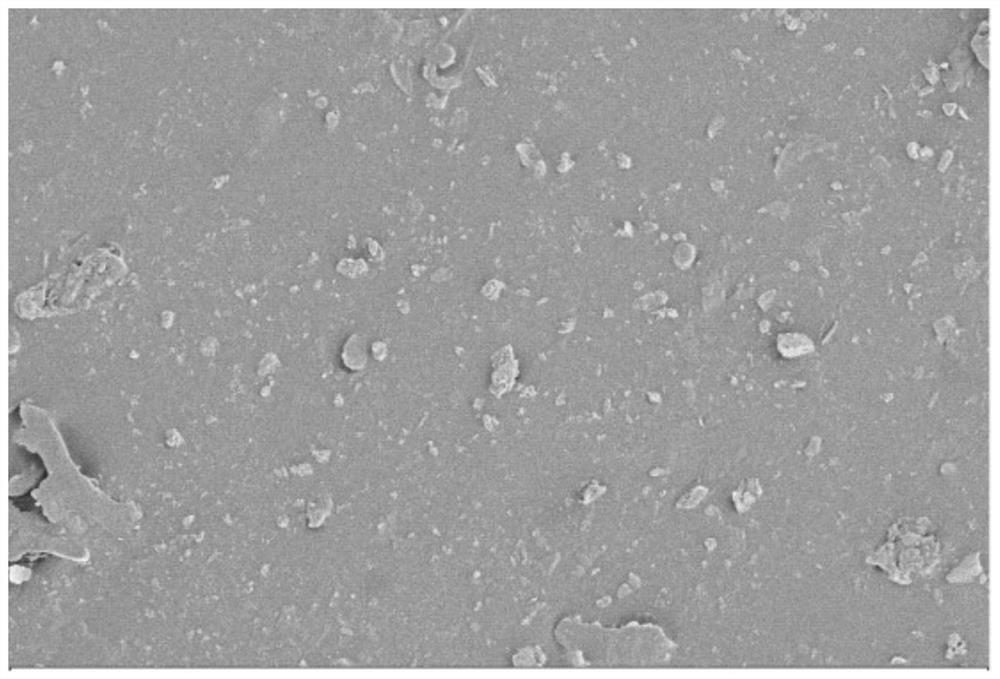

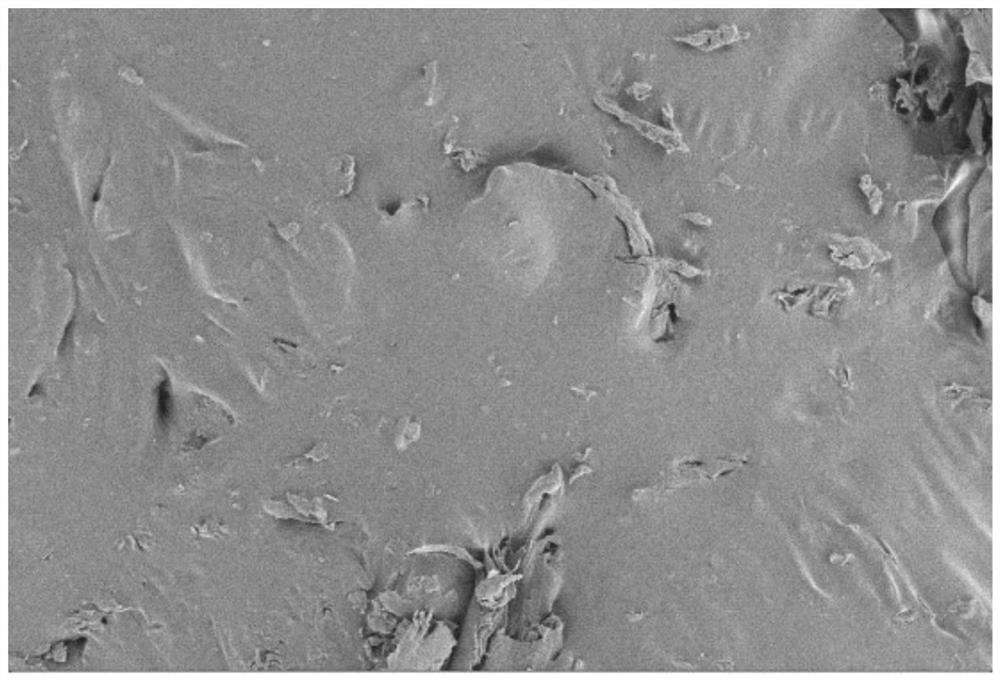

Image

Examples

Embodiment 1

[0040] A high temperature resistant modified asphalt pavement repair material, comprising the following mass parts: 85 parts of base asphalt, 19 parts of grafted SBS modifier, 3 parts of polyphosphoric acid (PPA), tackifier (methyl cellulose ) 6 parts, stabilizer (polyvinyl alcohol) 4 parts, anti-aging agent (UV-531) 5 parts. Among them, the grafted SBS modifier is prepared by mixing the YH-801 type SBS (ie, styrene and butadiene block copolymer) with the coupling agent in proportion, and the coupling reaction is obtained, wherein the coupling agent is For KH-560, the mixing ratio is SBS:KH-560=50:1, which is the case for the grafted SBS modifiers in the following examples.

[0041] The preparation method of the above-mentioned high temperature resistant modified asphalt pavement repairing material comprises the following steps: the preparation process includes melting, premixing, shearing and development; during the melting process, the solid base asphalt is burnt into a liqu...

Embodiment 2

[0043] A high temperature resistant modified asphalt pavement repair material, comprising the following mass parts: 81 parts of base asphalt, 19 parts of grafted SBS modifier, 2 parts of polyphosphoric acid (PPA), tackifier (methyl cellulose ) 8 parts, stabilizer (polyvinyl alcohol) 5 parts, anti-aging agent (UV-531) 6 parts.

[0044] The preparation method of the above-mentioned high-temperature-resistant modified asphalt pavement repair material includes the following steps: the same as the first embodiment, the modified asphalt pavement repair material must be prepared through 4 processes; the solid matrix asphalt is burnt by liquefied petroleum gas during the melting process It is in liquid state and should be stored properly for weighing. In order to make PPA better promote the compatibility of SBS and base asphalt, it is necessary to carry out the premixing stage. Weigh the liquid base asphalt, grafted SBS modifier and polyphosphoric acid according to the above mass frac...

Embodiment 3

[0046] A high temperature resistant modified asphalt pavement repair material, comprising the following substances in parts by mass: 79 parts of base asphalt, 16 parts of grafted SBS modifier, 2 parts of polyphosphoric acid, and 7 parts of tackifier (methyl cellulose) , 4 parts of stabilizer (polyvinyl alcohol), 4 parts of anti-aging agent (UV-531).

[0047] The preparation method of the above-mentioned high-temperature-resistant modified asphalt pavement repairing material comprises the following steps: taking the base asphalt that has been burnt into a liquid state according to the required parts and adding it to the modification system; adding the base asphalt, grafted SBS modifier, poly Preliminary mixing of polyphosphoric acid. Under mechanical stirring, the stirring rate is 800-1000r / min, the stirring time is 15min, and the temperature is 180°C to ensure that the compatibility between SBS and base asphalt is good; then methyl cellulose , polyvinyl alcohol, and UV-531 are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com