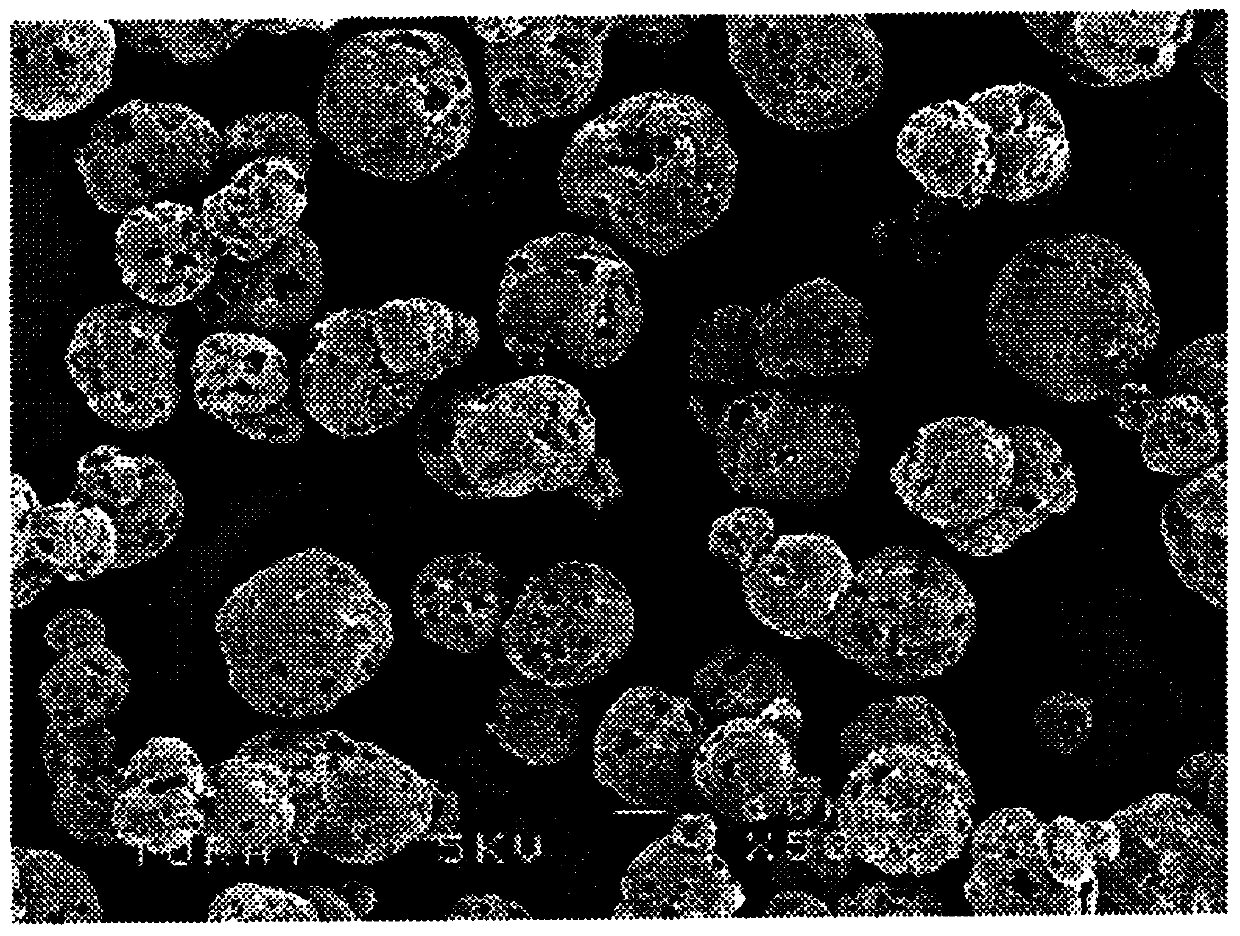

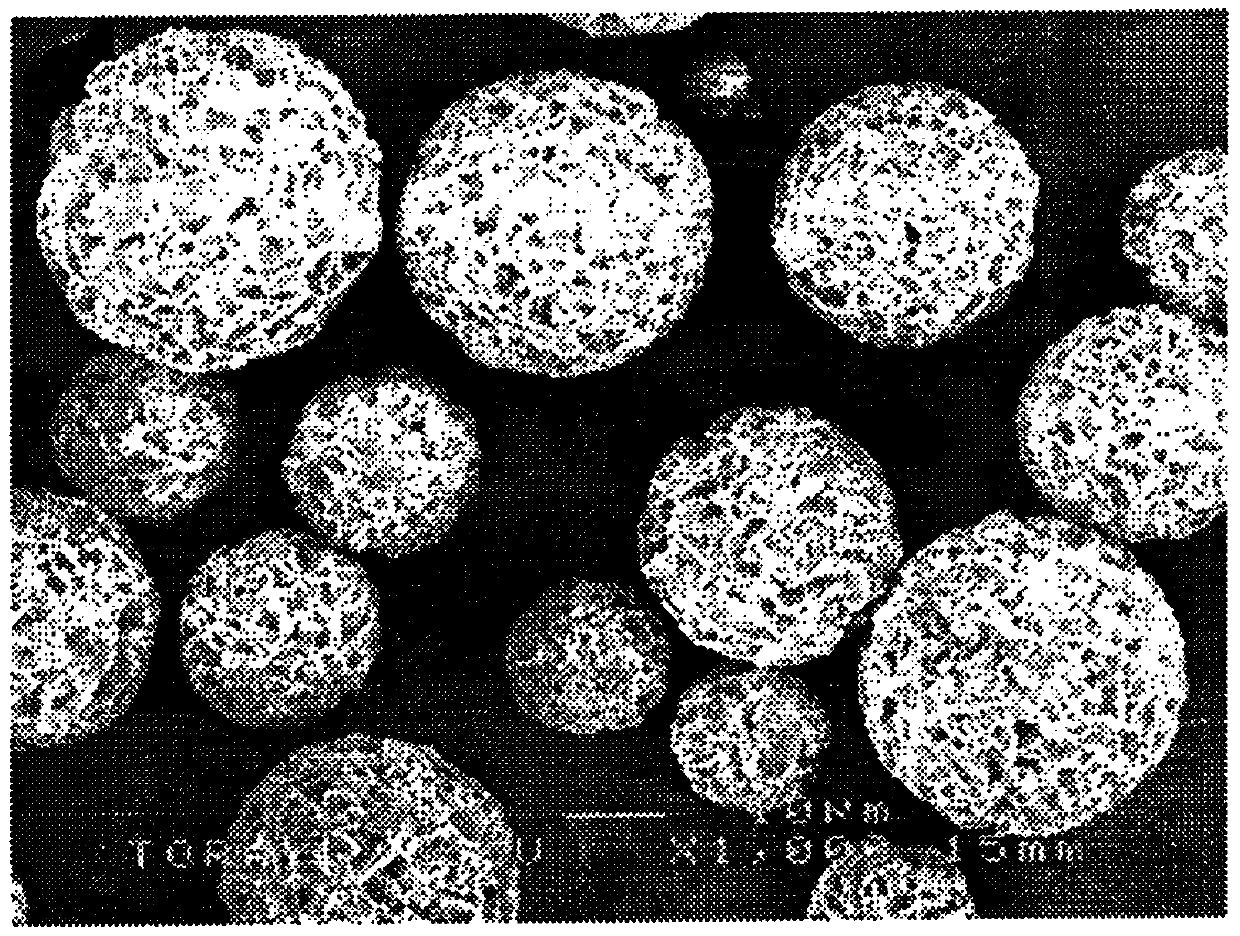

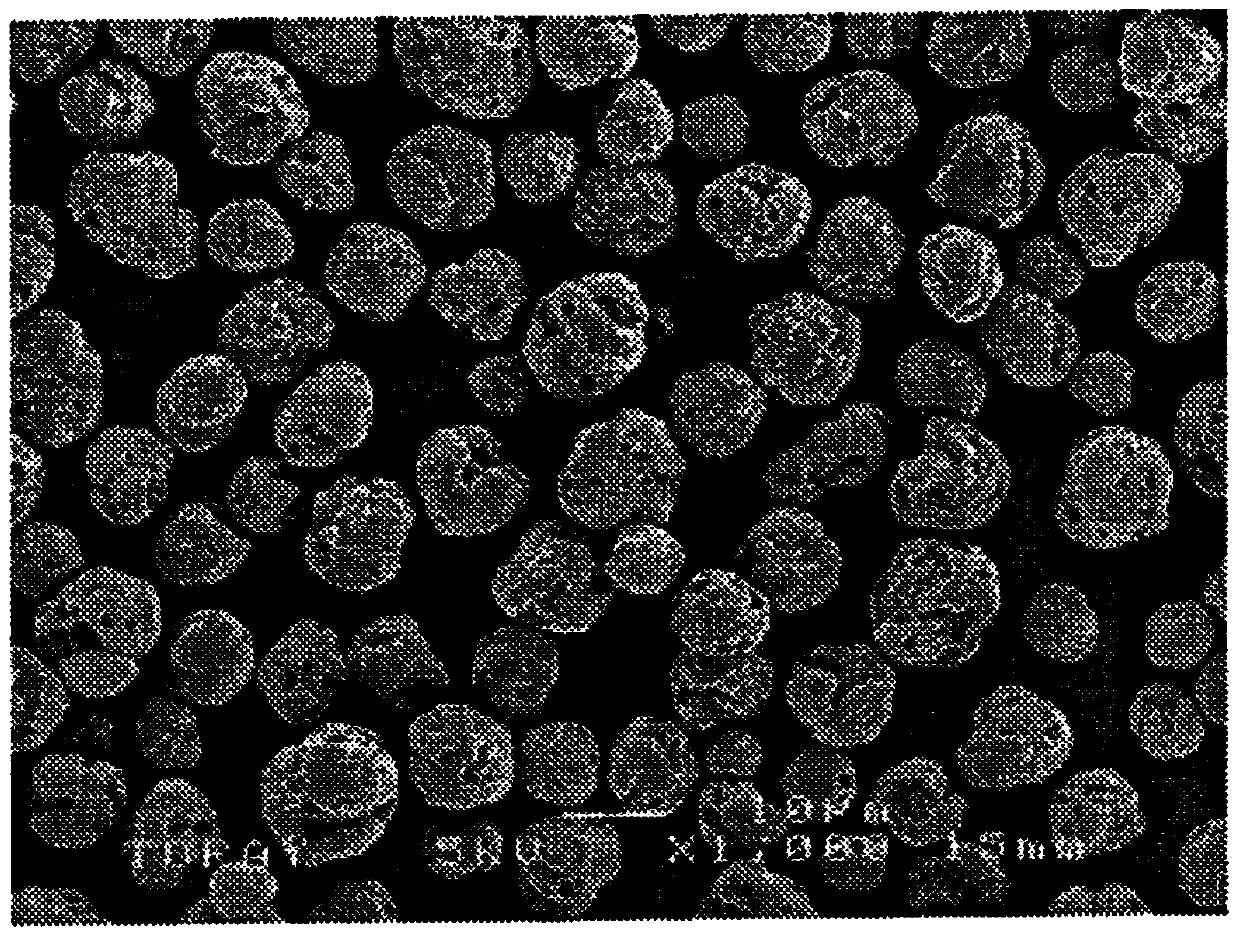

Method for producing microparticles of polylactic acid-based resin, microparticles of polylactic acid-based resin and cosmetic using same

A technology of polylactic acid-based resin particles, applied in cosmetics, cosmetics, cosmetic preparations, etc., can solve the problems of unclear manufacturing methods of polylactic acid-based resin particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0155] The present invention will be specifically described below based on examples, but the present invention is not limited by them.

[0156] (1) Determination of melting enthalpy and crystallization temperature

[0157] Using a differential scanning calorimeter (Robot DSCRDC220 manufactured by Seiko Instruments Co., Ltd.), the temperature was raised to 200° C. under a nitrogen atmosphere at a rate of 20° C. / min. Measurement was performed based on the area of the peak showing the heat of fusion near 160° C. calculate.

[0158] In addition, the crystallization temperature was measured using the above-mentioned apparatus, after raising the temperature to 200°C under the same conditions, and then measuring it at a cooling rate of 1°C / min. melting temperature.

[0159] (2) Weight average molecular weight

[0160] (i) Molecular weight measurement of polylactic acid resin (A)

[0161] The weight average molecular weight is a molecular weight calculated by comparing with a ca...

manufacture example 1

[0191] Production Example 1 Production Method 1 of Polylactic Acid

[0192]Add 70.2 g of L-lactide (manufactured by Aldrich: optical purity of 98% ee or higher), 30.1 g of D-lactide (manufactured by Aldrich: optical purity of 98% ee or higher) and 1.1 g of octanol into a stirring device In a reaction vessel, it was uniformly dissolved in a nitrogen atmosphere at 150° C., and then 0.90 g of tin octoate (manufactured by Aldrich) was added to a toluene solution adjusted to a concentration of 10% by mass in dry toluene, and polymerization was carried out for 6 hours. After completion of the polymerization reaction, the reactant was dissolved in chloroform, and reprecipitated while stirring in methanol, and the monomer and catalyst were removed to obtain a solid content. The obtained solid content was filtered, heated and vacuum-dried at 80° C. to obtain a polylactic acid-based resin having a copolymerization ratio of L / D=70 / 30, an enthalpy of fusion of 0 J / g, and a Mw (PMMA conver...

manufacture example 2

[0193] Production Example 2 Production method 2 of polylactic acid

[0194] Instead of using 49.9 g of L-lactide (manufactured by Aldrich: optical purity of 98% ee or higher), 49.8 g of D-lactide (manufactured by Aldrich: optical purity of 98% ee or higher), 0.95 g of octanol, and tin octoate (Manufactured by Aldrich) except 0.95 g, under the same conditions as in Production Example 1, a polylactic acid-based resin having a copolymerization ratio of L / D=50 / 50, an enthalpy of fusion of 0 J / g, and a Mw (PMMA conversion) of 9800 was obtained. . The SP value of this polymkeric substance is 23.14 (J / cm2) by above-mentioned calculation method 3 ) 1 / 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com