Three-dimensional electro-fenton water treatment method

A technology of water treatment and three-dimensional electricity, which is applied in the direction of sterilization/microdynamic water/sewage treatment, etc., can solve the problems that the efficiency cannot meet the industrial application, and achieve the effect of effective recovery, high efficiency, and overcoming environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] a. The activated carbon particles prepared from coconut shells were pickled and washed with water, then dried for later use, and ferric nitrate solution with 0.05 mol / L of zero-valent metal was prepared, and the dried active carbon was added to the ferric nitrate solution, stirred for 2 hours, and left to stand Settled, removed the supernatant, added 50 mL of pure water to wash and repeated 3 times, dried the loaded activated carbon at a temperature of 120 °C, and reduced the dried activated carbon in a hydrogen atmosphere reduction furnace at a temperature of 300 °C in a hydrogen atmosphere, and stored in Standby in the dust-free test bench;

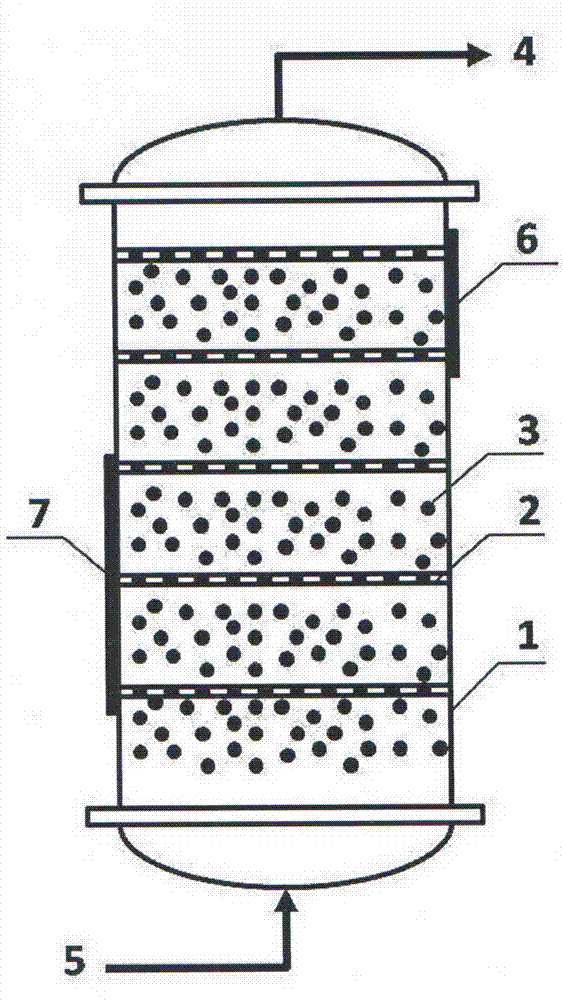

[0025] b. Equivalent arrangement of Ti / Sb-SnO in reactor 1 2 Porous electrode plate 2, Ti / Sb-SnO 2 The spacing between the porous electrode plates 2 is 2 cm, in Ti / Sb-SnO 2 Between the porous electrode plates 2 is placed a catalyst 3 that uses activated carbon to support zero-valent metal iron in step a to form a combination of...

Embodiment 2

[0031]a. The activated carbon granules prepared from apricot shells were pickled and washed with water, then dried for later use, and a copper nitrate solution with 0.05 mol / L of zero-valent metal was prepared, and the dried activated carbon was added to the copper nitrate solution, stirred for 2 hours, and left to stand Settled, removed the supernatant, added 50 mL of pure water to wash and repeated 3 times, dried the loaded activated carbon at a temperature of 120 °C, and reduced the dried activated carbon in a hydrogen atmosphere reduction furnace at a temperature of 300 °C in a hydrogen atmosphere, and stored in Standby in the dust-free test bench;

[0032] b, in the reactor 1, there are titanium mesh porous electrode plates 2 equally arranged, the spacing between the titanium mesh porous electrode plates 2 is 2 cm, and step a is placed between the titanium mesh porous electrode plates 2 to load zero with activated carbon. Catalyst 3 of valence metal copper nitrate forms a...

Embodiment 3

[0038] a. The activated carbon powder prepared from petroleum coke is pickled and washed with water, then dried for later use, and a nickel nitrate solution of 0.05 mol / L of zero-valent metal is prepared, and the dried activated carbon is added to the nickel nitrate solution, and after stirring for 2 hours, the Settled for sedimentation, removed the supernatant, added 50 mL of pure water to wash and repeated 3 times, dried the loaded activated carbon at a temperature of 120 °C, and reduced the dried activated carbon in a hydrogen atmosphere reduction furnace at a temperature of 300 °C in a hydrogen atmosphere, and stored Standby in a dust-free laboratory bench;

[0039] B, be provided with the stainless steel plate porous electrode plate 2 that equally arranges in reactor 1, the spacing between the stainless steel plate porous electrode plate 2 is 2 cm, between the stainless steel plate porous electrode plate 2, be placed with step a to load with activated carbon The catalyst ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com