A kind of preparation method of high-performance copper/aluminum composite pipe

An aluminum composite and high-performance technology, which is applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve problems such as high equipment requirements, high quality requirements for sealing welding, and fracture of brittle compound layers. Simple and equipment, improve subsequent cold processing performance, improve the effect of bonding state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

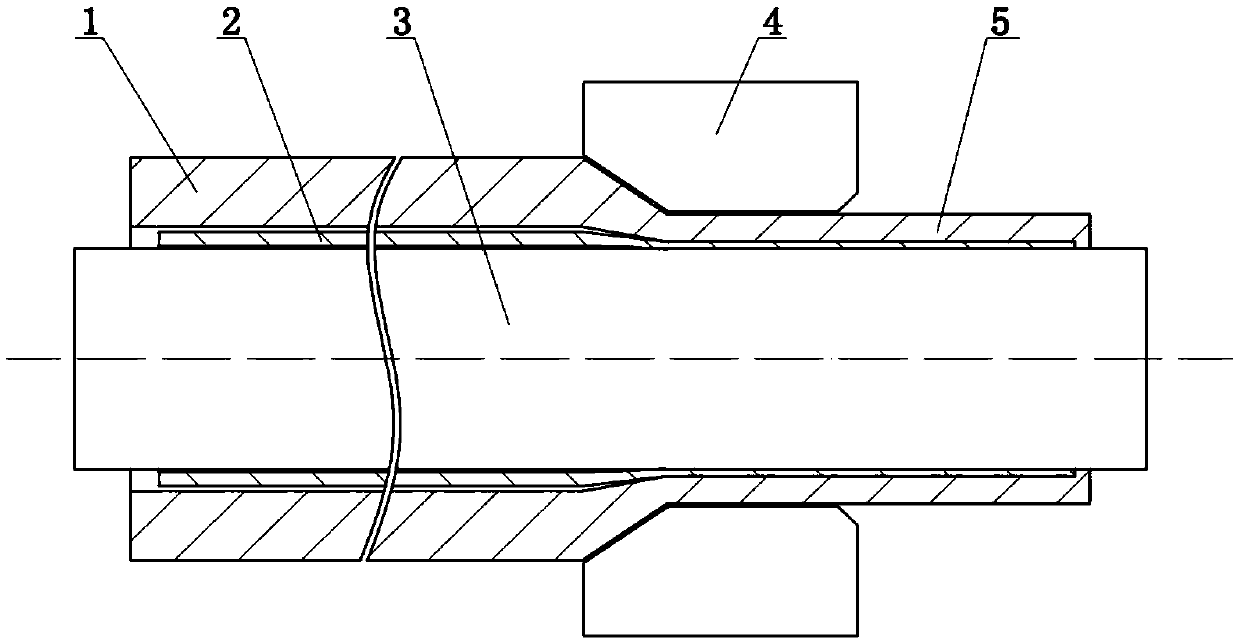

[0024] Preparation of metallurgically bonded copper / aluminum (outer aluminum and inner copper) bimetallic composite pipes.

[0025] (1) Surface treatment: the aluminum tube adopts 3003 aluminum alloy tube with a specification of Φ17×2mm, the copper tube adopts a pure copper tube with a specification of Φ12.7×0.55mm, the gap between the casings is 0.15mm, and the mandrel is hardened with a specification of Φ11.4mm. Degreasing the copper and aluminum tubes with 5% NaOH solution, then pickling with 10% HCl solution, and then grinding the inner surface of the aluminum tube and the outer surface of the copper tube with a wire brush to form a fresh metal matrix .

[0026] (2) Casing combination: Put the polished copper tube into the aluminum tube, and then insert the mandrel into the copper tube to ensure that the copper tube is shorter than the aluminum tube, the front end of the mandrel is the longest, and the surface of the mandrel is evenly coated with graphite emulsion lubrica...

Embodiment 2

[0031] Preparation of metallurgically bonded copper / aluminum (outer copper and inner aluminum) bimetal composite pipes.

[0032] (1) Surface treatment: the copper tube adopts a pure copper tube with a specification of Φ17×0.5mm, the aluminum tube is a pure aluminum tube with a specification of Φ15.8×2.1mm, the gap between the casings is 0.1mm, and the mandrel is a mold with a Φ11.4mm For steel, use 5% NaOH solution to degrease the copper and aluminum tubes, then pickle the copper and aluminum tubes with 10% HCl solution, and then use a wire brush to polish the inner surface of the copper tube and the outer surface of the aluminum tube to make them fresh metal base.

[0033] (2) Casing assembly: put the polished aluminum tube into the copper tube, evenly coat the surface of the mandrel with lubricating oil and insert it into the aluminum tube.

[0034] (3) Heating and heat preservation: Blow argon gas into the assembled double-layer tube, and then put it into a heating furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com